Properties & Applications of Molybdenum Copper Alloy Molybdenum copper alloy is one of the important materials indispensable for the development of modern technology. It has both the characteristics of molybdenum and copper and has good comprehensive properties. In this article, let’s take a look at the properties and applications of molybdenum copper alloys. Properties of […]

Tags: Advanced Refractory Metals, Applications of Molybdenum Copper Alloy, ARM, manufacturer & supplier of refractory metals & alloys, Molybdenum, Molybdenum Alloys, Molybdenum Copper Alloys, Properties of Molybdenum Copper Alloy, refractory alloys, Refractory Metals, rhenium, tantalum, titanium, Tungsten, Zirconium

Tantalum Powder Preparation Methods Tantalum powder is powdered metal tantalum, dark gray, or silver-gray, which is an important raw material for the preparation of capacitors and tantalum materials. In this article, let’s take a deeper look at the tantalum powder preparation methods. Before going any further, let’s figure out the types of tantalum powder. Types […]

Tags: Advanced Refractory Metals, ARM, capacitor grade tantalum powder, metallurgical grade tantalum powder, methods for preparing tantalum powder, Molybdenum, physical properties and chemical composition of the tantalum powder., rhenium, tantalum, Tantalum Powder, titanium, Tungsten, types of tantalum powder, Zirconium

Applications of Molybdenum Rhenium Alloys So far, rhenium is the most effective element to improve the properties of molybdenum alloys. The addition of rhenium greatly reduces the plastic-brittle transition temperature of the molybdenum alloy, so that the molybdenum-rhenium alloy has good room temperature performance. At the same time, it can increase the recrystallization temperature of […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, Molybdenum Alloys, Molybdenum Rhenium Alloy Applications, Molybdenum-rhenium Alloys, rhenium, Rhenium Alloys, tantalum, titanium, Tungsten, Zirconium

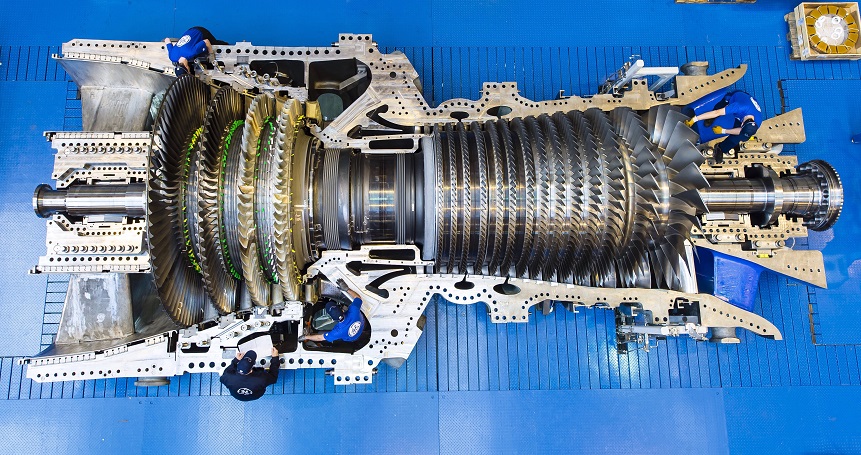

Refractory Metals & Alloys for Aerospace Refractory metals refer to metals with melting points above 2000°C. They include tungsten, molybdenum, tantalum, niobium, rhenium, and vanadium. The common characteristics of refractory metals and their alloys are high melting point, high strength at high temperatures, and good corrosion resistance to liquid metals. Their use temperature range is 1100~320℃, […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, Molybdenum Alloys, Niobium, Niobium alloys, refractory alloys, Refractory Metals, refractory metals & alloys, rhenium, Rhenium Alloys, tantalum, tantalum alloys, Tungsten, Tungsten alloys, tungsten-copper composite material, Vanadium, vanadium alloys

South America Surpasses China in Molybdenum Production and Becomes the Largest Molybdenum Producer in the World According to the latest data from the International Molybdenum Association (IMOA), global molybdenum production in the second quarter of 2020 was 67,222 tons, an increase of 3% from the first quarter, and a 3% increase from the second quarter of […]

Tags: Advanced Refractory Metals, ARM, International Molybdenum Association, Molybdenum, Molybdenum Alloys, molybdenum metal, Molybdenum Production, refractory alloys, Refractory Metals, rhenium, tantalum, titanium, Tungsten, Zirconium

Tungsten Molybdenum Iron Alloy for Steelmaking Tungsten molybdenum iron alloy can be simply understood as an alloy composed of three metal elements: tungsten, molybdenum, and iron. Because of its excellent physical and chemical properties, it is widely used in the steel industry. According to statistics, 40% of tungsten and 80% of molybdenum are currently used in […]

Tags: Advanced Refractory Metals, ARM, manufacturer & supplier of refractory metals & alloys, Molybdenum, refractory alloys, Refractory Metals, rhenium, tantalum, titanium, Tungsten, Tungsten Molybdenum Iron Alloy, Zirconium

Properties and Applications of Tantalum Tantalum is very hard, and its melting point is as high as 2996, second only to tungsten and rhenium. Tantalum is ductile and can be drawn into filaments or processed into tantalum foil. Its coefficient of thermal expansion is very small, only 6.6 percent per degree Celsius rise. In addition, its toughness […]

Tags: Advanced Refractory Metals, Applications of Tantalum, ARM, Chemical Properties of Tantalum, Properties of Tantalum, refractory alloys, Refractory Metals, tantalum, tantalum foil, tantalum metal, Tantalum Powder

Heat Treatment of Titanium Alloy Titanium alloy is favored by people for its excellent room temperature and high-temperature mechanical properties, outstanding corrosion resistance, and high strength. It has become an important structural material in the aviation and aerospace industries. The heat treatment of titanium alloy can significantly increase the strength of the alloy so that it can […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, refractory alloys, Refractory Metals, rhenium, tantalum, titanium, titanium alloy, Tungsten, Zirconium

Tips for Using Titanium Pans Daily maintenance of pans and utensils is very important, and titanium pans are no exception. Although titanium pans have advantages over ordinary pans, such as no coating, less oily smoke, physical non-stickiness, sturdiness, and durability, etc., they still need to be carefully taken care of and cleaned in time to keep the pan […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, refractory alloys, Refractory Metals, rhenium, tantalum, Tips for Cleaning Titanium Pans, titanium, Titanium alloys, Titanium Pans, Tungsten, Zirconium

Titanium Alloy Investment Casting Technology The castings produced by the investment casting method have low surface roughness and precise dimensions. In addition, the investment casting method can cast castings with complex shapes and improve the utilization rate of metallic materials. However, the investment casting process is more complicated and difficult to control, and the materials used and […]

Tags: Advanced Refractory Metals, ARM, Carbon Refractory Materials, Metallic Mater, Molybdenum, Oxide Ceramic Materials, Refractory Materials, tantalum, titanium, titanium alloy, Titanium Alloy Investment Casting, titanium alloy investment casting process, Tungsten

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.