Properties & Applications of Molybdenum Copper Alloy

Properties & Applications of Molybdenum Copper Alloy

Molybdenum copper alloy is one of the important materials indispensable for the development of modern technology. It has both the characteristics of molybdenum and copper and has good comprehensive properties. In this article, let's take a look at the properties and applications of molybdenum copper alloys.

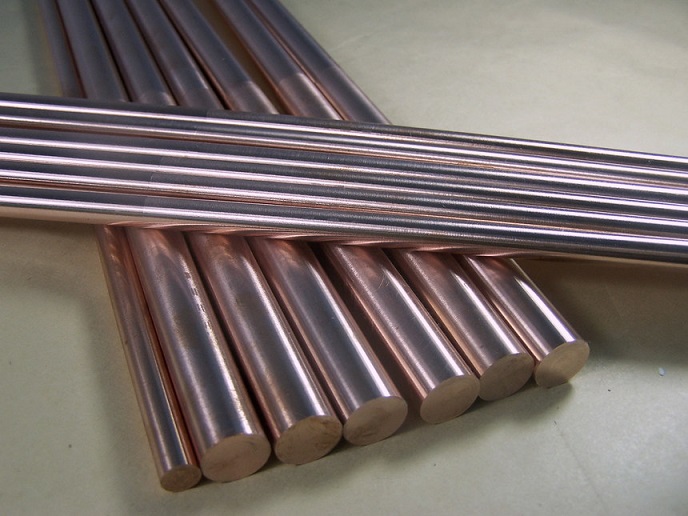

Molybdenum Copper Alloy

Properties of Molybdenum Copper Alloy

1. High Electrical and Thermal Conductivity

Molybdenum is an element with good electrical and thermal conductivity in addition to gold, silver, copper, and other metals. Therefore, the molybdenum-copper alloy composed of molybdenum and copper has high electrical and thermal conductivity.

2. Low Adjustable Coefficient of Thermal Expansion

Copper has a high thermal expansion coefficient, but molybdenum has a very low thermal expansion coefficient. Therefore, in practical applications, the required lower thermal expansion coefficient can be made according to the combination of different components so that they can be matched and combined with the thermal expansion coefficients of other materials to avoid thermal stress damage caused by excessive thermal expansion coefficient differences.

3. Special High-temperature Performance

The melting point of molybdenum is 2610°C, while the melting point of copper is only 1083°C. Molybdenum-copper alloy has both good strength and certain plasticity at room temperature and medium temperature. When the temperature exceeds the melting point of copper, the copper can liquefy and evaporate to absorb heat and play a cooling role. This performance can be used as high-temperature materials for special purposes, such as electrical contacts under the action of high-temperature arcs.

4. Non-magnetic

Both molybdenum and copper are non-ferromagnetic metals, so the molybdenum copper alloy is an excellent non-magnetic material.

5. Low Gas Content and Good Vacuum Performance

The oxides of molybdenum or copper are easy to reduce, and their N, H, C, and other impurities are also easy to remove so that they can maintain extremely low outgassing under vacuum and have good vacuum performance.

6. Good Machinability

Pure molybdenum metal itself is difficult to machine due to its higher hardness and brittleness. Molybdenum-copper alloys are advantageous for machining because the hardness of the material decreases and the plasticity increases after copper is added, and they can be processed into parts with complex shapes.

Applications of Molybdenum Copper Alloy

Because of the above-mentioned properties, the application prospects of molybdenum copper alloys are broad. Mainly include:

1. Used as a vacuum contact, which is currently being promoted and applied in a large area;

2. Used as a conductive heat dissipation element, which can meet the requirements of high electrical conductivity, thermal conductivity, heat resistance, vacuum performance, and constant thermal expansion coefficient of high-power integrated circuits and microwave devices;

3. Used as some instrumental components with special requirements, and can meet its non-magnetic, constant thermal expansion coefficient, high elastic modulus, high electrical thermal conductivity, etc.;

4. Used for high-temperature parts of rockets and missiles with lower temperatures, and can also replace molybdenum as parts in other weapons, such as extended-range guns;

5. Used as a solid dynamic seal, a reinforcing rib for sliding friction, a water-cooled electrode tip of a high-temperature furnace, and an electrode for electrical machining, etc.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the properties & applications of molybdenum copper alloy. If you want to learn more about molybdenum & molybdenum alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as molybdenum, tantalum, rhenium, tungsten, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}