Compared to other metals, titanium is a lustrous and silver transition metal with low density and high corrosion resistance to sea water, aqua regia and chlorine, etc. Titanium is alloyed with aluminum, manganese, iron, molybdenum and other metals to increase strength, to withstand high temperatures, and to lighten the resultant alloy.

Advanced Refractory Metals a leading supplier of titanium products. We offer low pricing and great lead times on all our materials, and we’re capable of supplying custom materials per any specs/drawings you provide us with.

Introduction Titanium-clad copper is a composite material that combines the excellent corrosion resistance of titanium with the superior electrical conductivity of copper. This unique combination makes it an invaluable material across various industries, particularly in environments where both high conductivity and corrosion resistance are required. This article will discuss the features, uses, and benefits of […]

Introduction Metal fiber felt is an innovative material widely used in various filtration applications. It possesses exceptional properties, including high porosity, excellent permeability, and resistance to high temperatures and corrosion. This article explores the different types of metal fiber felt, their unique benefits, and the wide array of applications ranging from aerospace to chemical processing. […]

Tags: Filtration, Metal Fiber Felt

Introduction In the realm of advanced materials, metallic foams represent a fascinating and rapidly evolving area. These materials are notable for their unique combination of metal properties and foam structure. These intriguing characteristics are not found in traditional solid metals. How to Produce Metallic Foams? Producing metallic foams involves several methods. Each creates specific structural […]

Tags: Metallic Foam

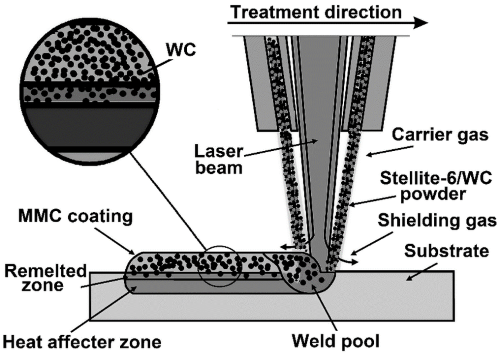

Introduction: Laser cladding is a versatile additive manufacturing process. It has gained significant traction in various industries for enhancing the surface properties of components. The success of laser cladding depends not only on the process parameters but also on the choice of material. Striking the right balance between price and performance is crucial. In this […]

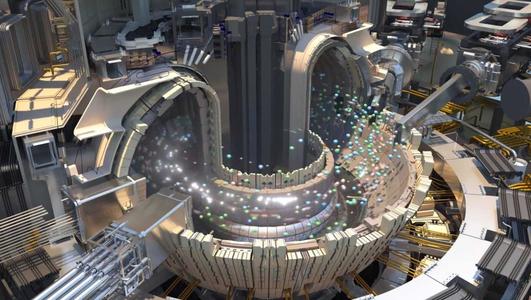

Introduction The aerospace industry stands at the forefront of human innovation. It is continually pushing the boundaries of what is technologically possible. Central to this progress are high-temperature materials. They enable the exploration of the skies and beyond. These high-temperature materials are meticulously designed to withstand extreme conditions. They play a pivotal role in the […]

Introduction The crust is the outermost layer of the Earth, making up 1% of the planet. It is composed of solid rocks and minerals formed, which are usually slowly formed over a long period of time. A range of elements can be found in the Earth’s crust, among which 7 of the 10 most abundant […]

Tags: 7 Most Abundant Metal Elements in Earth’s Crust, 7 Most Abundant Metal Elements in the Earth’s Crust, Aluminum Everywhere, Iron - the Most Used Metal, Magnesium - A Lightweight Metal, Potassium - Another Highly Reactive Element, Sodium and Salt, Titanium - Strong but Lightweight

Uses of Titanium Alloys in Civil Aircraft Titanium alloy is an alloy composed of titanium as a base material and other elements. It has the outstanding advantages of low density, high specific strength, good corrosion resistance, good heat and low-temperature resistance, non-magnetic, good impact resistance, and good welding performance. Therefore, it is widely used in the chemical […]

Tags: Advanced Refractory Metals, ARM, manufacturer & supplier of refractory metals & alloys, refractory alloys, Refractory Metals, tatanium fasteners, titanium, Titanium alloys, Titanium Alloys in Civil Aircraft, titanium metal, Uses of Titanium Alloys

Strengthening Mechanism of TZC Alloy TZC alloy, namely molybdenum–titanium–zirconium-carbon alloy, is an aluminum alloy composed of a high content of titanium, zirconium, carbon, and molybdenum, and its general composition is Mo-1.25Ti-0.15Zr-0.15C. Compared with TZM alloy, TZC alloy has better high-temperature resistance and greater strength and can be used as a mold for high-temperature heat processing of […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, Molybdenum Powder, powder metallurgy, powder metallurgy method, titanium, TZC Alloy, TZM Alloy, Zirconium

High-strength & High-elasticity Titanium Alloy Development Status Titanium alloy‘s high strength and low elastic modulus endow it with excellent elastic deformation ability, and it is widely used in the aerospace field as a structural and functional integrated material. In the 1950s, the United States first used titanium alloy bolts made of Ti-6Al-4V on B-52 bombers, which […]

Tags: Advanced Refractory Metals, ARM, High-elasticity Titanium Alloy, High-strength Titanium Alloy, manufacturer & supplier of refractory metals, Rubber Metal, Ti-2448, Ti-6Al-4V, titanium alloy fasteners, Titanium alloys, Types of Refractory Materials

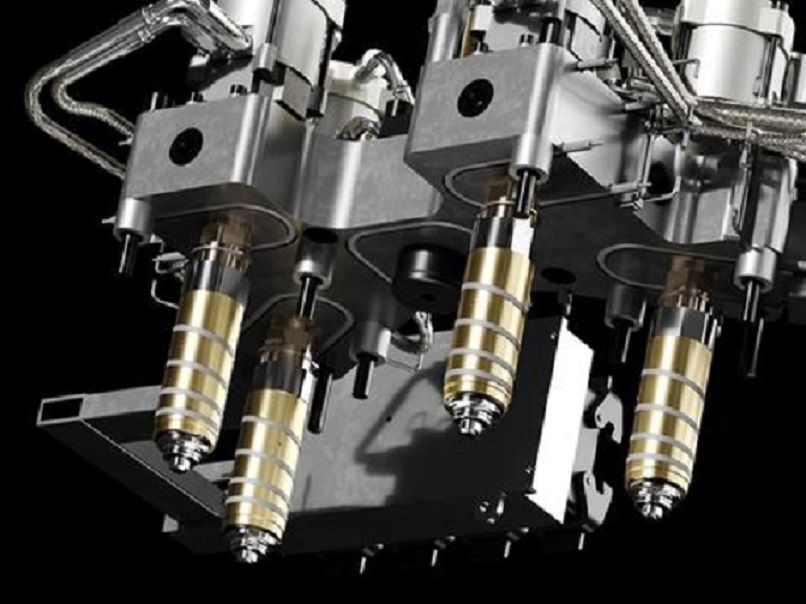

Titanium Zirconium Molybdenum (TZM) Alloy for Hot Runner Nozzles Why use titanium zirconium molybdenum (TZM) alloy for hot runner nozzles? In this article, we will try to find the answer to this question. According to reports, HRSflow is completing the expansion of its 3,000-square-meter factory in San Polo di Piave, Italy. The expansion is designed according […]

Tags: Advanced Refractory Metals, ARM, injection molding process, manufacturer & supplier of refractory metals & alloys, Molybdenum, powder metallurgy, titanium, Titanium-Zirconium-Molybdenum Alloy, types of refractory metals and alloys, TZM, TZM Alloy, Zirconium

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.