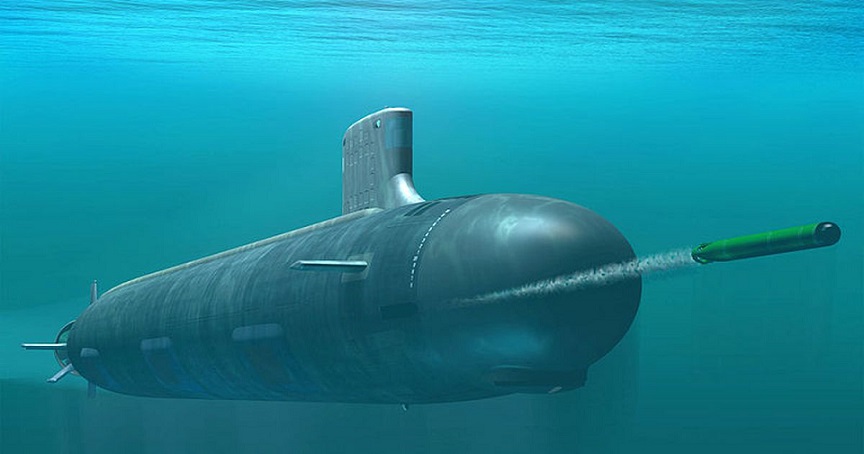

Titanium-Aluminum-Niobium-Zirconium-Molybdenum Alloy for Submersible Shell Compared with titanium alloys, titanium-aluminum-niobium–zirconium–molybdenum alloys are more suitable for producing deep submersible shells with high comprehensive performance. This is mainly due to its superior welding performance, impact toughness, fracture toughness, and corrosion resistance. In this article, let’s take a closer look at the titanium-aluminum-niobium-zirconium-molybdenum alloy for submersible shells. Since the […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, Niobium, refractory alloys, Refractory Metals, titanium, Titanium alloys, Titanium-Aluminum-Niobium-Zirconium-Molybdenum Alloy, Zirconium

Molybdenum Sputtering Target for Semiconductors Nowadays, sputtering targets have a wide range of applications, from the semiconductor industry to the thin film deposition of various materials in integrated circuit processing. Sputtering is a mature technology that can deposit thin films of multiple materials onto substrates of various shapes and sizes. In order to obtain the required characteristics […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, molybdenum alloy target, Molybdenum Sputtering Target, molybdenum tantalum target, molybdenum titanium target, Niobium, pure molybdenum targe, Refractory Metals, Sputtering Target, titanium, Tungsten, TZM plate

Tungsten Alloy Radioactive Source Container Tungsten alloy radioactive source container refers to a tungsten alloy shielded container used to store and transport radiopharmaceuticals, radionuclide-labeled compounds, or biological agents. Among them, radiopharmaceuticals refer to a class of special drugs that contain radionuclides for medical diagnosis and treatment, such as radiotherapy drugs 32P, 89Sr, 90Y, etc. that emit […]

Tags: Advanced Refractory Metals, ARM, leading manufacturer & supplier of refractory metals & alloys, Molybdenum, Niobium, rhenium, tantalum, titanium, Tungsten, Tungsten alloys, types of refractory metals and alloys, Zirconium

TZM Alloy for Rocket Nozzle TZM alloy, also known as titanium zirconium molybdenum alloy, is commonly used in the production of rocket nozzles because of its high melting point, small volume expansion effect, good thermochemical stability, and other characteristics. In this article, let’s take a deeper look at the TZM alloy for rocket nozzle. Rocket nozzles […]

Tags: Advanced Refractory Metals, ARM, manufacturer & supplier of refractory metals & alloys, Molybdenum, Niobium, powder metallurgy, rhenium, tantalum, titanium, Titanium-Zirconium-Molybdenum Alloy, Tungsten, types of refractory metals and alloys, TZM Alloys, Zirconium

Application of Niobium in Stomatology Niobium is a shiny gray metal with a melting point of 2468 ℃ and a boiling point of 4742 ℃. Due to its excellent physical and chemical properties, niobium has a wide range of applications in many fields. In this article, let’s take a deeper look at the application of niobium […]

Tags: Advanced Refractory Metals, Application of Niobium, Application of Niobium in Oral Implantation, Application of Niobium in Oral Medicine, Application of Niobium in Oral Radiation, Application of Niobium in Oral Restoration, Application of Niobium in Oral Surgery, Application of Niobium in Orthodontics, ARM, Niobium, refractory alloys, Refractory Metals

Application of Niobium in the Steel Industry The application fields of niobium can basically be divided into the steel industry and the non-steel industry. The former accounts for more than 85% of the world’s niobium consumption, while the latter accounts for less than 15%. In this article, let’s take a closer look at the application of […]

Tags: Advanced Refractory Metals, Application of Niobium, Application of Niobium in Alloy Steel, Application of Niobium in Cast Iron, ARM, Niobium, niobium bars, Niobium in the Steel Industry, Refractory Metal, Types of Refractory Metals

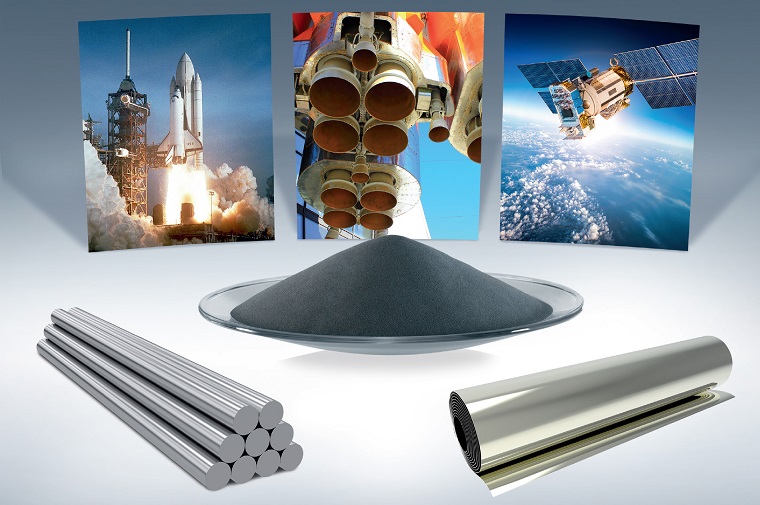

Refractory Metals & Alloys for Aerospace Refractory metals refer to metals with melting points above 2000°C. They include tungsten, molybdenum, tantalum, niobium, rhenium, and vanadium. The common characteristics of refractory metals and their alloys are high melting point, high strength at high temperatures, and good corrosion resistance to liquid metals. Their use temperature range is 1100~320℃, […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, Molybdenum Alloys, Niobium, Niobium alloys, refractory alloys, Refractory Metals, refractory metals & alloys, rhenium, Rhenium Alloys, tantalum, tantalum alloys, Tungsten, Tungsten alloys, tungsten-copper composite material, Vanadium, vanadium alloys

Titanium Aluminum Alloy Preparation & Applications As early as the 1970s, titanium aluminum alloy was known as a promising high-temperature resistant material. It has high strength and good high-temperature resistance, but due to its low ductility and poor workability, it has not been mass-produced and used in the industry. In order to improve the high-temperature resistance of Ti-Al […]

Tags: Advanced Refractory Metals, ARM, Chromium, Composite Material Technology, Copper, high-temperature resistant material, Ingot Metallurgy Technology, manganese, Molybdenum, Niobium, Powder Metallurgy Technology, Preparation and Processing Technology of the Titanium Aluminum Alloy, Rapid Condensation Technology, The Applications of the Titanium Aluminum Alloy, Titanium Aluminum Alloy, Titanium Aluminum Alloy Application, Titanium Aluminum Alloy Preparation, Vanadium

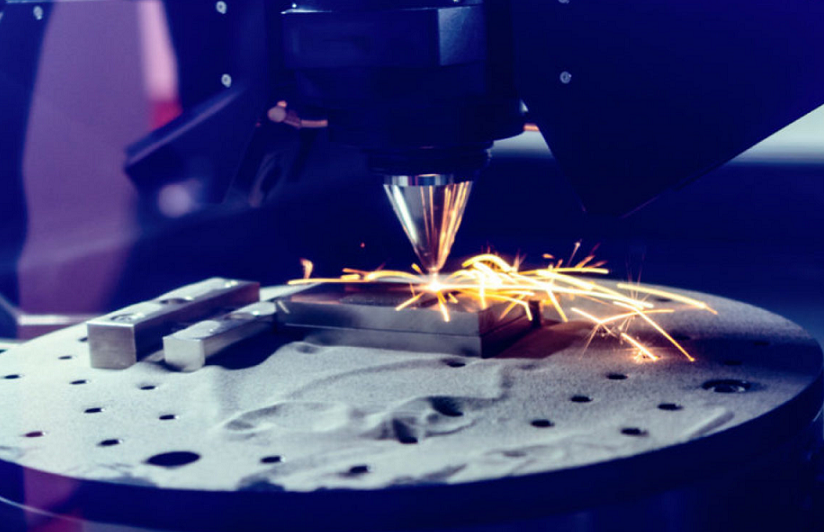

3D Printing Is Used to Develop Refractory Metal Components for Nuclear Weapons 3D printing has always been favored by the military manufacturing and aerospace industries. Metal Technologies (MTI), a manufacturing service provider from Oregon, USA, won a contract from the US Navy. Under this contract, MTI will develop and demonstrate advanced aerospace additive manufacturing technology for the […]

Tags: 3D Printing, Advanced Refractory Metals, ARM, Molybdenum, Niobium, refractory alloys, Refractory Metal, Refractory Metal Components, refractory metal parts, rhenium, tantalum, titanium, Tungsten, Zirconium

How Was Vanadium Discovered? Vanadium is a silvery-white transition metal with element symbol V, atomic number 23, and an atomic weight of 50.9414. Vanadium has a high melting point of 1890 ° C and is called refractory metal together with niobium, tantalum, tungsten, and molybdenum. Due to its excellent physical and chemical properties, vanadium and vanadium alloy […]

Tags: Advanced Refractory Metals, ARM, Chromium, How Was Vanadium Discovered?, Molybdenum, Niobium, Refractory Metal, rhenium, tantalum, The Discovery of Vanadium, titanium, Tungsten, Vanadium, vanadium alloy, Vanadium Element, Vanadium Metal, Zirconium

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.