This blogging site provides professional knowledge of tungsten, molybdenum, tantalum, columbium to expand the markets for refractory metals. So if you want to know a bit more about refractory metals and related processed products, then please take a look through our blogs.

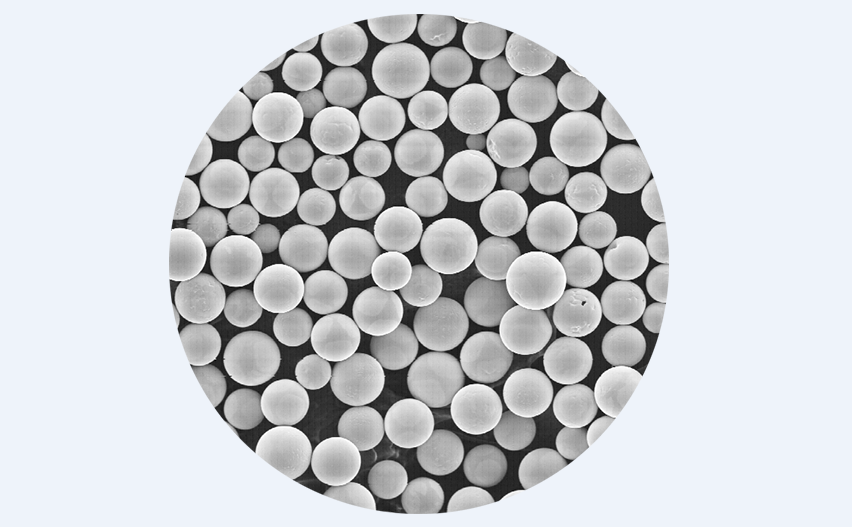

Introduction Spherical tantalum powder has emerged as a game-changer in the aerospace and medical industries. This advanced powder form offers unique properties that make it an ideal choice for critical applications in these sectors. In this article, we will explore how spherical tantalum powder is breaking barriers and revolutionizing the aerospace and medical industries. Hope […]

Tags: 3D Printing, Additive Manufacturing, Aerospace, Biocompatibility, corrosion resistance, Medical, Spherical Tantalum Powder

Zr702 & Zr705 Zirconium the element (Zr, 40) is located in Group 4 and Period 5 in the periodic table. It is a silver-gray metal with impressive strength and corrosion resistance. The applications of zirconium include heat exchangers, pipe and fittings, pump and valve housings, nuclear power reactors, sputtering targets, etc. There are mainly two […]

Tags: corrosion resistance, Strength, Zirconium, Zr702, Zr705

Introduction As energy demand increases and environmental concern rises, people start to search for new renewable energy sources such as wind, solar, and geothermal power. Lots of advanced techniques including artificial photosynthesis and water-splitting reaction are developed to generate solar fuels. Moreover, photoactive semiconductor materials like Niobium are also utilized to enhance the efficiency of […]

Tags: How Does Artificial Photosynthesis Happen, How Does Water Splitting Occur, Niobium-based Photoactive Water Splitting Catalyst, Uses of Niobium

1. Introduction to Alloys An alloy is a blend of 2 or more chemical elements, one of which is supposed to be metal. Different substances of controlled amount are added to a metal to form alloys with desirable properties. Examples of alloys like stainless steel, bronze, and brass are applied to various fields including construction, […]

Tags: Introduction to Alloys, Melting Point Diagrams of An Compound, Melting Points of Alloys, The Melting Point and Melting Range, The Melting Point of An Alloy Is Lower

Refractory metals are a group of metallic elements that are highly resistant to heat, wear, and tear. These metals are popular and widely used because of their unique and desirable properties and behaviors, especially their resistance to corrosion and their extraordinary resistance to wear and heat. These refractory metals are mostly used in the fields […]

Tags: high density tungsten powder, Refractory Metals, Tungsten (W)

How is titanium used in aerospace/aeronautics applications? Titanium was discovered in 1791 and has since become a hot product in the metallurgy manufacturing industry. Until the start of the Cold War, titanium was yet to begin its entry into the military and aerospace/aeronautics industries. Fast-forward to today, substances such as titanium tubing are a prime […]

Tags: Application Of Titanium In Aerospace, Electron beam welding of titanium alloy, How is titanium used in aerospace/aeronautics applications?, Laser welding of titanium alloy, titanium alloy

How to Prolong the Service Life of Molybdenum Wire? Molybdenum wire is made of precious metals such as molybdenum. Pure molybdenum wire is used for winding-core wires, brackets, lead wires, heating elements, molybdenum foil tapes, and spraying of auto parts. Lanthanum molybdenum wire can be used for wire-wound core glass seals, molybdenum foil tapes, furnace heating […]

Tags: Advanced Refractory Metals, ARM, How to Prolong the Service Life of Molybdenum Wire, lanthanum molybdenum wire, Molybdenum, molybdenum wire, molybdenum wire for cutting, pure molybdenum wire, refractory alloys, Refractory Metals, yttrium-molybdenum wire

Types and Uses of Molybdenum Wire Molybdenum is a silver-white metal with a high melting point and does not undergo oxidation reaction with air at room temperature. Because molybdenum has the advantages of high strength, high melting point, corrosion resistance, and wear resistance, it is widely used in steel, petroleum, chemical, electrical and electronic technology, medicine, […]

Tags: Advanced Refractory Metals, ARM, high-temperature molybdenum wire, manufacturer & supplier of refractory metals & alloys, metal with a high melting point, Molybdenum, Molybdenum Wires, pure molybdenum wire, sprayed molybdenum wire, Types of Molybdenum Wire, Uses of Molybdenum Wire, wire-cut molybdenum wire

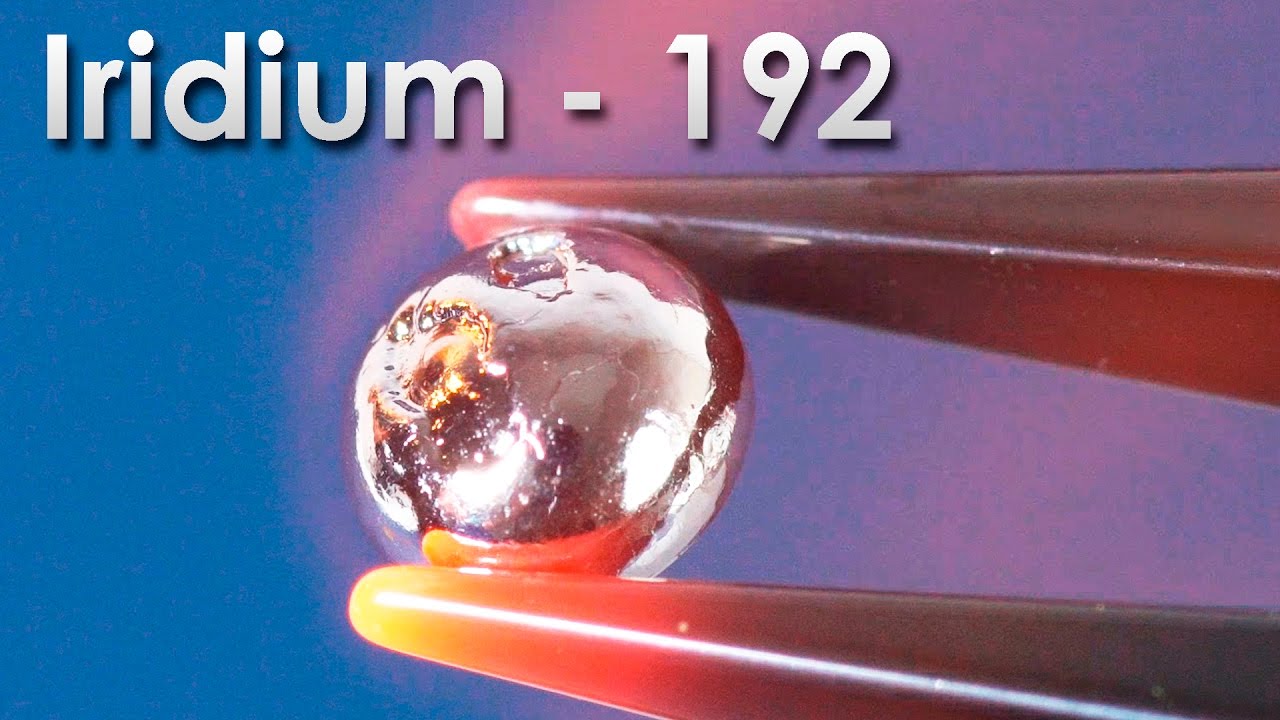

How Does Iridium Work in Modern Industries? How does iridium work In modern industries? If you are new to the world of refractory metal iridium, you may ask such a question. Actually, the high melting point, hardness, and corrosion resistance of Iridium and its alloys determine most of its applications. Iridium and especially iridium–platinum alloys or osmium–iridium […]

Tags: Advanced Refractory Metals, ARM, iridium, iridium crucibles, iridium–platinum, iridium–platinum alloys, osmium–iridium alloys, platinum alloys, Pure Iridium, refractory metal iridium, Refractory Metals

8 Excellent Properties of Titanium That Make It A New Marine Metal Thanks to its excellent properties, titanium, and titanium alloys have been widely used in the industry and our everyday life. For instance, titanium is called “marine metal” due to its excellent properties such as being light in weight, high in strength, and resistant to corrosion. In […]

Tags: Advanced Refractory Metals, ARM, Marine Metal, properties of titanium, Refractory Metals, supplier of refractory metals, titanium, Titanium alloys, titanium plates, titanium wires

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.