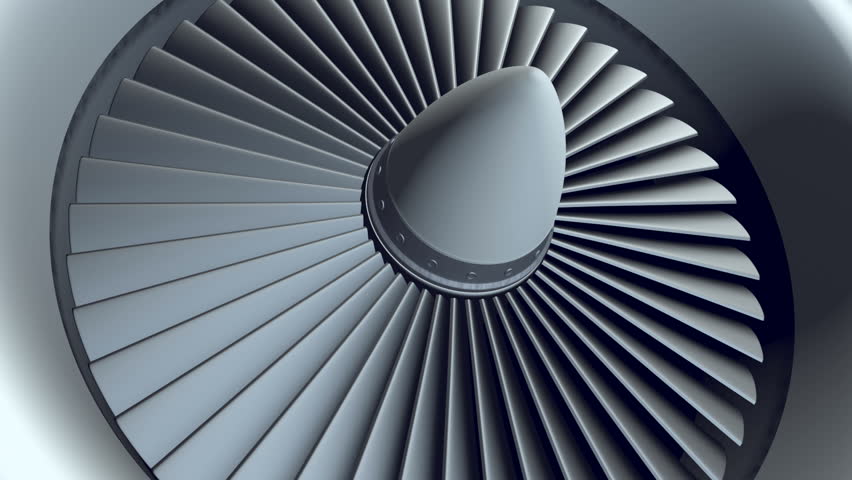

How is titanium used in aerospace/aeronautics applications? Titanium was discovered in 1791 and has since become a hot product in the metallurgy manufacturing industry. Until the start of the Cold War, titanium was yet to begin its entry into the military and aerospace/aeronautics industries. Fast-forward to today, substances such as titanium tubing are a prime […]

Tags: Application Of Titanium In Aerospace, Electron beam welding of titanium alloy, How is titanium used in aerospace/aeronautics applications?, Laser welding of titanium alloy, titanium alloy

Application of Titanium in Watches As we all know, watches are necessities in people’s daily life. Traditional watches are made of brass and the surface is electroplated with Ni. The surface layer of this watch contains a large amount of nickel, which often causes a “nickel allergic reaction” when worn. Therefore, since the 1970s, relevant scientific and […]

Tags: Advanced Refractory Metals, Application Of Titanium, ARM, powder metallurgy, pure titanium, Refractory Metal, Ti-6Al-4V, titanium alloy, Titanium in Watches, titanium metal

Heat Treatment of Titanium Alloy Titanium alloy is favored by people for its excellent room temperature and high-temperature mechanical properties, outstanding corrosion resistance, and high strength. It has become an important structural material in the aviation and aerospace industries. The heat treatment of titanium alloy can significantly increase the strength of the alloy so that it can […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, refractory alloys, Refractory Metals, rhenium, tantalum, titanium, titanium alloy, Tungsten, Zirconium

Titanium-Iron Hydrogen Storage Alloy Hydrogen storage alloy is a new type of alloy that can store hydrogen. This kind of alloy can absorb hydrogen and release it under certain conditions. It is often used in large batteries, especially electric vehicles, hybrid electric vehicles, and high-power applications. There are three main series of hydrogen storage alloys: rare […]

Tags: Advanced Refractory Metals, Application of Titanium-Iron Hydrogen Storage Alloy, ARM, refractory alloys, Refractory Metals, TiFe hydrogen storing alloy, TiFe hydrogenated alloy, titanium, titanium alloy, titanium hydrogen storage alloy

Titanium Alloy Oil Well Pipe Advantages & Applications In the petroleum industry, the oil well pipe has a pivotal position, and its quality and performance have a significant impact on the development of the petroleum industry. In oil and natural gas exploration and development, a lot of oil well pipes are consumed. Compared with oil […]

Tags: Advanced Refractory Metals, ARM, refractory alloys, Refractory Metals, titanium, titanium alloy, Titanium Alloy Oil Well Pipe, Titanium Alloy Oil Well Pipe Advantages, Titanium Alloy Oil Well Pipe Applications

Characteristics and Applications of Titanium Titanium is a silver-white metal with a melting point of 1668°C. Compared with other metals, titanium has more and better characteristics, so it is used in various scenarios. So in this article, let’s take a look at the characteristics and applications of titanium. 1. Low Density, High Specific Strength The […]

Tags: Advanced Refractory Metals, Applications Of Titanium, ARM, Characteristics of Titanium, TA7, TC4, Ti-2.5Zr-1.5Mo, Ti-5Al-2.5Sn, titanium, titanium alloy

Application of Titanium Alloys on Ships Titanium alloy is an alloy composed of titanium as a base material and other elements. It has the outstanding advantages of low density, high specific strength, good corrosion resistance, good heat and low-temperature resistance, non-magnetic, good impact resistance, and good welding performance. The hull components made of titanium alloy greatly improve […]

Tags: Advanced Refractory Metals, Application of Titanium Alloys, ARM, marine titanium alloy, refractory alloys, Refractory Metals, titanium, titanium alloy, Titanium Alloys on Ships, titanium fasteners, use of titanium on ships

Titanium Alloy Investment Casting Technology The castings produced by the investment casting method have low surface roughness and precise dimensions. In addition, the investment casting method can cast castings with complex shapes and improve the utilization rate of metallic materials. However, the investment casting process is more complicated and difficult to control, and the materials used and […]

Tags: Advanced Refractory Metals, ARM, Carbon Refractory Materials, Metallic Mater, Molybdenum, Oxide Ceramic Materials, Refractory Materials, tantalum, titanium, titanium alloy, Titanium Alloy Investment Casting, titanium alloy investment casting process, Tungsten

Forging Technology of Titanium Alloy Titanium alloy has excellent characteristics such as high strength, good corrosion resistance, non-magnetic, good welding performance, and a series of other advantages such as superconductivity, hydrogen storage, and memory. Therefore, titanium alloys are widely used in some cutting-edge fields such as aerospace, military industry, marine development, and petrochemicals. In the application of […]

Tags: Advanced Refractory Metals, Applications of Titanium Alloy Forgings, ARM, Forging of Titanium Alloy, Forging Technology of Titanium Alloy, manufacturer & supplier of refractory metals, refractory metals & alloys, Ti-6Al-2Sn-4Zr-6Mo alloy, Ti-6Al-4V alloy, titanium alloy

Application of Titanium Alloy in Golf Club Golf is a sport deeply loved. People have high requirements for golf equipment, not only for its beautiful appearance but also for light clubs and fast and accurate hitting speed, which promotes the continuous development of golf club manufacturing. In the early 1990s, the Japanese began to introduce […]

Tags: Advanced Refractory Metals, Application of Titanium Alloy, Application of Titanium Alloy in the Golf Club, Application Status of Titanium Alloy in Golf Club, ARM, Golf Club, refractory alloys, Refractory Metals, titanium, titanium alloy, Titanium Alloy Iron Clubhead, Titanium Alloy Putter Head, Titanium Alloy Wooden Clubhead

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.