Choosing the Right Material for Laser Cladding: Price and Performance Comparison

Introduction:

Laser cladding is a versatile additive manufacturing process. It has gained significant traction in various industries for enhancing the surface properties of components.

The success of laser cladding depends not only on the process parameters but also on the choice of material. Striking the right balance between price and performance is crucial.

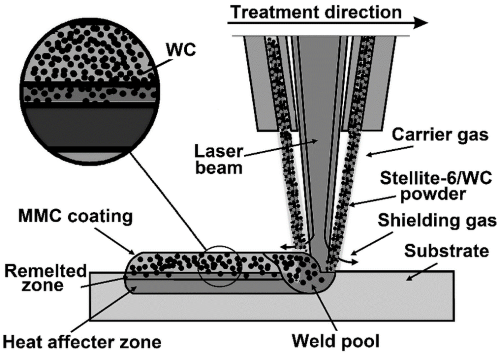

Laser Cladding Processes [1]

In this article, we delve into the considerations for selecting materials for laser cladding. Hope that you enjoy this comprehensive price and performance comparison.

1. Understanding Laser Cladding:

Laser cladding is a versatile surface treatment technique. It involves depositing a layer of material onto a substrate to enhance its properties. Laser cladding is also known as laser metal deposition (LMD) or laser cladding deposition.

The choice of materials for laser cladding is crucial, as it directly influences the performance, durability, and functionality of the treated components. Here are some common materials used in laser cladding:

2. Common Materials for Laser Cladding:

a. Nickel-Based Alloys:

Advantages:

- High corrosion resistance;

- Excellent high-temperature performance;

- Suitable for aerospace and high-temperature applications.

Considerations:

- Higher material cost compared to some alternatives;

b. Stainless Steels:

Advantages:

- Good corrosion resistance;

- Moderate cost;

- Widely used in various industries, including automotive and chemical processing;

Considerations:

- Limited performance in high-temperature applications;

c. Tool Steels:

Advantages:

- High hardness and wear resistance;

- Suitable for cutting and forming applications;

- Used in tooling and die applications;

Considerations:

- Moderate to high material cost;

d. Carbide Alloys:

Advantages:

- Exceptional hardness and wear resistance;

- Suitable for abrasive conditions;

- Commonly used in mining and drilling equipment;

Considerations:

- Higher material cost;

e. Titanium Alloys:

Advantages:

- Lightweight with a high strength-to-weight ratio;

- Excellent corrosion resistance;

- Used in aerospace, medical, and marine applications;

f. Aluminum Alloys:

Advantages:

- Lightweight and corrosion-resistant;

- Widely used in automotive and aerospace industries;

- Enhances thermal conductivity;

g. Cobalt-Chromium Alloys:

Advantages:

- High hardness and wear resistance;

- Suitable for applications with high mechanical stress;

- Used in medical implants and aerospace components;

h. Ceramic Reinforcements:

Advantages:

- Enhanced hardness and wear resistance;

- Used in combination with metal matrices for improved properties;

- Commonly employed in high-wear environments;

3. Performance Considerations:

The success of laser cladding is intricately tied to the choice of materials. This decision hinges on a delicate balance between price and performance. Let’s focus on wear resistance, corrosion resistance, temperature resistance, and mechanical properties in this part. Understanding these factors is paramount for the optimal outcomes in laser cladding.

- Wear Resistance:

Choose materials with high hardness and wear resistance for applications exposed to abrasive conditions or frequent friction.

- Corrosion Resistance:

In corrosive environments, opt for materials with superior corrosion resistance to ensure the longevity of the treated components.

- Temperature Resistance:

Consider the operating temperature range of the application. Some materials excel in high-temperature conditions. Thus, they are suitable for specific industries like aerospace and energy.

- Mechanical Properties:

Assess the mechanical properties required for the application. There are tensile strength, toughness, and fatigue resistance.

4. Cost Considerations:

Beyond the realm of performance considerations, the cost considerations matter as well. The evaluation of material costs, process efficiency, and the impact on tooling and equipment wear becomes pivotal in the pursuit of achieving optimal outcomes. In this segment, we unravel the factors that influence the financial landscape of laser-cladding ventures.

- Material Cost:

Evaluate the cost of the cladding material per unit volume. Some high-performance alloys come with a higher price tag.

- Process Efficiency:

Consider the efficiency of the laser cladding process with different materials. Some materials may require additional processing steps, impacting overall costs.

- Tooling and Equipment Wear:

Assess the wear on tooling and equipment during the laser cladding process. Some materials may accelerate wear and require more frequent maintenance.

5. Case Studies:

As laser cladding continues to establish itself as a pivotal technology in surface treatment, the real-world applications of this method extend across diverse industries. The case studies span the aerospace industry, mining equipment, and oil and gas components. They illustrate the direct impact of material selection on the efficacy and longevity of laser cladding applications.

- Aerospace Industry:

In aerospace applications, nickel-based alloys are often preferred for their high-temperature performance and corrosion resistance.

- Mining Equipment:

Carbide alloys or high-strength tool steels may be suitable for components subjected to abrasive wear in mining equipment.

- Oil and Gas Components:

Stainless steels with good corrosion resistance are commonly used in the oil and gas industry where exposure to harsh environments is prevalent.

Conclusion:

Selecting the right material for laser cladding involves a meticulous balance between price and performance considerations. It is crucial to conduct a thorough analysis of the specific application's demands and weigh the advantages and disadvantages of each material option.

By understanding the unique properties of materials like nickel-based alloys, stainless steels, tool steels, and carbide alloys, industries can make informed decisions that optimize both performance and cost-effectiveness in laser cladding applications.

With the right material choice, laser cladding proves to be a powerful tool for extending life and enhancing the functionality of critical components across diverse industries.

With more than two decades of expertise, Advanced Refractory Metals (ARM) excels in delivering top-notch metals and alloys at competitive rates. Our capability extends to tailoring this product to your specific requirements. Send us an inquiry if you are interested.

Reference:

[1] Bartkowski, Dariusz & Matysiak, Waldemar & Wojtko, Kamil. (2018). Stellite-6 surface layers reinforced with hard and refractory WC particles produced on steel for metal forming. IOP Conference Series: Materials Science and Engineering. 393. 012093. 10.1088/1757-899X/393/1/012093.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}