Metallic Foams: Production, Properties, and Diverse Applications

Introduction

In the realm of advanced materials, metallic foams represent a fascinating and rapidly evolving area. These materials are notable for their unique combination of metal properties and foam structure. These intriguing characteristics are not found in traditional solid metals.

How to Produce Metallic Foams?

Producing metallic foams involves several methods. Each creates specific structural and physical properties in the final product. The main techniques are:

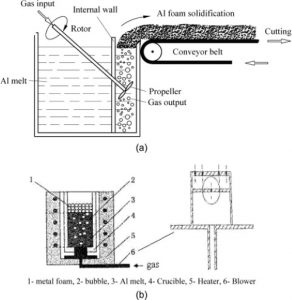

1. Gas Injection Method:

This method involves injecting a gas or a gas-releasing blowing agent into molten metal. As the metal cools and solidifies, it traps the gas bubbles and forms a porous, foam-like structure consequently.

Gas Injection Method [1]

This technique is suitable for a variety of metals and alloys and allows for control over the size and distribution of the pores.

2. Powder Metallurgy Technique:

In this approach, metal powders are mixed with a foaming agent. The foaming agent decomposes to release gas upon heating. The mixture is compacted and then heated to a temperature where the metal softens but does not fully melt. Thus, they allow the gas released by the foaming agent to create a porous structure.

This method is particularly useful for creating foams with very fine and uniform pore structures.

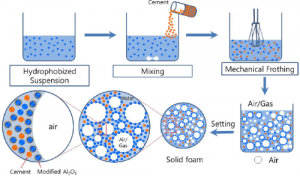

3. Direct Foaming Method:

This involves directly introducing gas (such as air, argon, or nitrogen) into molten metal. You can achieve this through mechanical stirring or by injecting the gas through a nozzle. Additives and stabilizers are often used to help maintain the foam's structure as it solidifies.

Direct Foaming Method [2]

This method is useful for creating foams with large, irregular pores.

4. Space Holder Technique:

Here, a space-holding material can be salt, sand, or another particulate. These materials are mixed with metal powder. After compaction, the space-holding material is removed (often by dissolution or heating), leaving behind a porous metal structure.

This technique allows for the production of metallic foams with very specific and controlled pore sizes and shapes.

5. Electrodeposition:

In this method, metallic foams are produced by depositing metal onto a substrate through an electrochemical process. By controlling the deposition parameters, porous structures can be created.

This method is typically useful for coatings or thin foam layers.

6. Replication Method:

This involves impregnating a porous template (like polyurethane foam) with metal or alloy, typically in molten form. Once the metal solidifies, the template is removed. The removal method is often burning or chemical dissolution, leaving behind a metal foam that replicates the template's structure.

What Are the Common Types of Metallic Foams?

Metallic foams are fascinating materials with a variety of types. They come with unique properties and applications. The common types of metallic foams include:

- Aluminum Foams: Aluminum foams are perhaps the most widely used due to their low weight, good strength, and corrosion resistance. They find common use in automotive and aerospace industries for impact absorption, lightweight structures, and thermal management.

- Nickel Foams: They stand out for their high thermal and electrical conductivity. They are useful in batteries, particularly in electrodes for nickel-metal hydride (NiMH) and lithium-ion batteries. They also find use in filtration and catalysis applications due to their large surface area.

- Copper Foams: Like nickel, copper foams are excellent conductors of heat and electricity. They find applications in heat exchangers, electrode materials for batteries, and electromagnetic shielding.

- Titanium Foams: These foams possess biocompatibility and similar mechanical properties to bone. Their common uses include medical implants, like orthopedic and dental implants. They also feature in aerospace applications for their high strength-to-weight ratio and corrosion resistance.

- Steel Foams: Steel foams combine the strength of steel with the reduced weight of a foam structure. They are useful in structural applications where high strength is necessary, and also in sound absorption and vibration damping.

- Magnesium Foams: These are lighter than aluminum foams. These foams find their use in applications where weight reduction is critical, such as in some automotive and aerospace components. Their biodegradability also opens up potential applications in biodegradable implants.

- Composite Metallic Foams: These composites combine different metals or metal and non-metal materials to achieve specific properties. For example, a metal-ceramic composite foam might offer both high-temperature resistance and good mechanical strength.

What Are the Properties of Metallic Foams?

With these materials, metallic foams exhibit a unique set of properties:

- Lightweight: Their porous structure makes them significantly lighter than solid metals. They have become ideal for weight-sensitive applications.

- High Strength-to-Weight Ratio: Despite their lightness, they possess considerable strength, particularly in compression.

- Thermal Conductivity: These foams can conduct heat but at a reduced rate compared to solid metals. That’s quite useful in heat exchangers and insulation.

- Sound Absorption: The porous structure effectively absorbs sound. So, they are excellent for noise reduction applications.

- Energy Absorption: They can deform under stress without fracturing. This ability is valuable in impact absorption and vibration damping.

What Are the Diverse Applications of Metallic Foams?

The unique properties of metallic foams have led to their use in a wide range of applications:

- Automotive Industry: You can find metallic foams in car bodies and components for weight reduction, energy absorption in crash scenarios, and sound insulation.

- Aerospace: These foams are essential in lightweight structures for aircraft and spacecraft.

- Medical Devices: Their biocompatibility and similar structure to bone make them suitable for implants and prosthetic devices.

- Architecture and Construction: They find use in soundproofing, vibration damping, and even in decorative elements due to their aesthetic appeal.

- Heat Exchangers and Cooling Systems: Their thermal conductivity and surface area make them effective in heat dissipation applications.

Conclusion

Metallic foams are a remarkable class of materials. They combine the best aspects of metals and foams. Their production methods include Gas Injection Method, Powder Metallurgy Technique, Direct Foaming Method, Electrodeposition, etc. Each method yields different structural and physical properties in the final foam product.

As research and technology advance, we can expect to see even more innovative uses for these versatile materials. These uses are potentially revolutionizing various industries and opening new horizons in material science and engineering. For more information related to metallic foams, please check our homepage.

Reference:

[1] Porous Materials : Processing and Applications. Elsevier 2014. INSERT-MISSING-DATABASE-NAME Accessed 4 Feb. 2024.

[2] Pokhrel, Ashish & Seo, Dong & Lee, Seung & Kim, I.J.. (2013). Processing of Porous Ceramics by Direct Foaming: A Review. Journal of the Korean Ceramic Society. 50. 10.4191/kcers.2013.50.2.093.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}