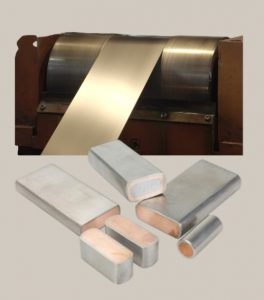

Titanium-Clad Copper Used in Electrolytic Copper Production

Introduction

Titanium-clad copper is a composite material that combines the excellent corrosion resistance of titanium with the superior electrical conductivity of copper. This unique combination makes it an invaluable material across various industries, particularly in environments where both high conductivity and corrosion resistance are required.

This article will discuss the features, uses, and benefits of titanium-clad copper. Hope that you can have a better understanding of this clad material.

What Is Titanium-Clad Copper?

Titanium-clad copper is a bimetallic product that consists of a core of copper or a copper alloy coated with a layer of titanium. The cladding process involves bonding titanium and copper under high pressure and temperature, creating a material that leverages the best properties of both metals. The copper core provides excellent electrical and thermal conductivity, while the titanium cladding offers outstanding resistance to corrosion, particularly in harsh environments. The composite comes with several benefits:

- Improved Mechanical Properties: The copper core provides excellent strength and structural integrity, while the titanium cladding adds toughness and resistance to physical wear and tear.

- Corrosion Resistance: Titanium is highly resistant to corrosion, particularly in harsh environments such as acidic or saline conditions. This makes titanium-clad copper ideal for use in corrosive environments.

- Thermal and Electrical Conductivity: Copper is known for its excellent electrical and thermal conductivity, while the titanium cladding protects the conductive properties of the copper core, ensuring consistent performance even in harsh conditions.

- Cost Efficiency: Using a less expensive core material like copper with a thin layer of expensive titanium reduces overall material costs while still providing the superior properties of titanium. Additionally, the extended lifespan and reduced maintenance requirements of titanium-clad copper components contribute to long-term cost savings.

How to Make Titanium-Clad Copper?

Titanium-clad copper is manufactured through a process called explosive welding, where a layer of titanium is bonded to a copper substrate. This method involves placing a sheet of titanium over a copper plate, with a precise amount of explosive material spread evenly across the titanium surface. The controlled explosion creates a high-velocity impact, causing the titanium to bond with the copper at an atomic level without melting either metal. This results in a strong metallurgical bond with excellent conductivity and corrosion resistance.

Post-explosion, the titanium-clad copper undergoes further processing to achieve the desired dimensions and surface finish. This typically includes heat treatment to relieve any residual stresses, followed by cold working or rolling to refine the material's thickness and improve its mechanical properties. The final product is a composite material that combines the beneficial properties of both metals, such as titanium's corrosion resistance and copper's excellent electrical conductivity, making it suitable for applications in the chemical, marine, and electrical industries.

Related reading:

Titanium Clad Copper & Its Production Methods

The Processing of Titanium Clad Copper Parts

How Is Titanium-Clad Copper Used in Electrolytic Copper Production?

Electrolytic copper production is a process that involves the refining of copper by electrolysis. In this process, impure copper is used as an anode, and pure copper is deposited onto the cathode. The electrolyte is typically a solution of copper sulfate and sulfuric acid, which is highly corrosive. This environment necessitates the use of materials that can resist corrosion while maintaining high electrical conductivity, making titanium-clad copper an excellent choice.

The clad material serves three main purposes: supporting the anode, conducting electricity, and resisting corrosion.

- First, the titanium-clad copper rods in electrolytic cells help increase current density and improve processing efficiency. In this process, the titanium cladding protects the copper conductor from corrosion, ensuring consistent current density and improving the quality of electrolytic products.

- They are also useful in electrolytic copper production due to their ability to carry large currents under highly corrosive conditions. The titanium layer prevents the copper core from corroding, thereby maintaining the integrity of the electrical conductor and ensuring long-term performance. This makes titanium-clad copper an ideal material for supporting metal anodes in electrolytic cells.

- Last, traditional bonding methods, such as suspended welding or rigid connections, can lead to several problems, including increased resistance, uneven current density, and corrosion. Yet, using titanium coated copper rods is a fundamental solution to eliminate the above unfavorable factors.

Broader Applications and Future Prospects

Beyond electrolytic copper production, titanium-clad copper is used in various other applications where corrosion resistance and electrical conductivity are crucial. These include chemical processing, marine engineering, power generation, and electronics.

- In chemical processing, titanium-clad copper components are used in equipment exposed to highly corrosive environments, such as heat exchangers, reactors, and piping systems.

- In marine engineering, they are used in shipbuilding and offshore platforms, where resistance to seawater corrosion is essential.

- In the power generation industry, titanium-clad copper is used in components that require high strength, conductivity, and corrosion resistance, such as connectors and battery components. The electronics industry also benefits from the use of titanium-clad copper in the manufacture of electronic components that demand both high conductivity and corrosion resistance.

As the demand for high-performance materials continues to grow, the future prospects for titanium-clad copper are promising. Advances in production techniques and bonding methods will likely further enhance the performance and reliability of this versatile material, opening up new applications and markets.

Conclusion

In summary, titanium-clad copper is an advanced composite material essential in electrolytic copper production. Its unique combination of high conductivity and exceptional corrosion resistance makes it invaluable across various industries. Beyond electrolytic copper production, titanium-clad copper's versatility extends to chemical processing, marine engineering, power generation, and electronics.

As demand for high-performance materials grows, advancements in production techniques and bonding methods will further enhance the capabilities of titanium-clad copper, opening new applications and markets.

Advanced Refractory Metals (ARM) offers high-quality titanium-clad materials at competitive prices. With extensive expertise in clad metals and their applications across various industries, ARM provides customized titanium-clad solutions tailored to your project's specific needs. Whether you require enhanced corrosion resistance, superior thermal conductivity, or unique design elements, ARM is the ideal choice.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}