Why use titanium zirconium molybdenum (TZM) alloy for hot runner nozzles? In this article, we will try to find the answer to this question. According to reports, HRSflow is completing the expansion of its 3,000-square-meter factory in San Polo di Piave, Italy. The expansion is designed according to lean production standards to make the hot runner assembly process more efficient. The goal is to ensure increased production capacity and provide customers with greater flexibility.

Titanium Zirconium Molybdenum (TZM) Alloy

Since its introduction into the industry, hot runners have played a key role in improving the injection molding process. Although the capital cost is greater than that of cold runners, its ultra-high production efficiency makes it a long-term and more economical choice. The improvement of system performance can produce parts with excellent appearance and increase part functions. In addition, the hot runner improves energy efficiency and saves plastic raw materials, thereby shortening cycle time and reducing part costs.

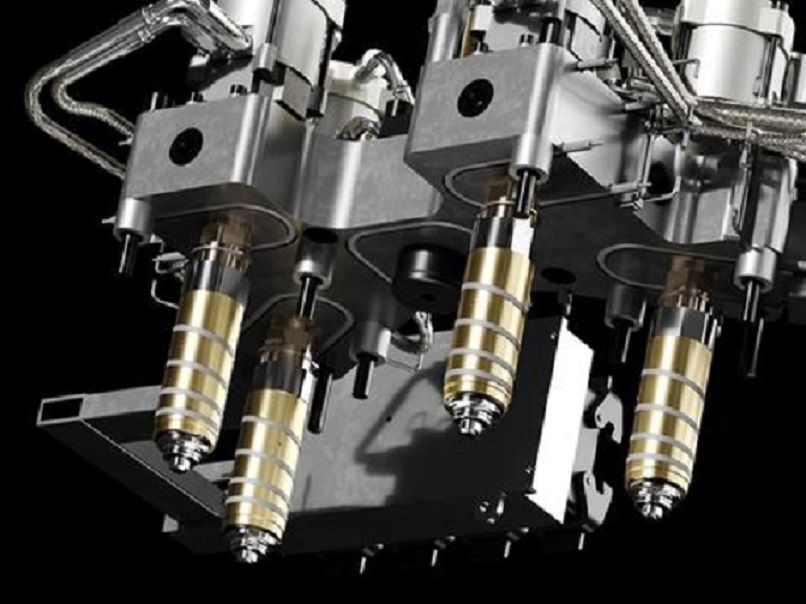

In view of the advantages of hot runners, the world’s large and small enterprises, including those mentioned above, are implementing hot runners and seeking various solutions for further optimization. Of course, the focus of this article is not on this, but on one of the important parts of the hot runner-the nozzle.

Hot runner technology is mainly to heat the plastic melt between the injection molding machine nozzle and the cavity to reduce the injection pressure so that the plastic melt can fill the cavity smoothly, so as to obtain high-quality plastic products. And the choice of nozzle material is related to the production efficiency, cost, and quality of the finished product of the hot runner system.

Pure molybdenum has a very high melting point, good strength, low thermal expansion coefficient, and excellent thermal conductivity, and is a good comprehensive candidate material for most high-temperature applications. Titanium Zirconium Molybdenum (TZM) Alloy is a molybdenum alloy. Like pure molybdenum, TZM alloy can be produced by powder metallurgy.

Although TZM alloy is 25% more expensive than pure molybdenum, in some applications, the additional cost is offset by its increased strength at high temperatures. The recrystallization temperature of TZM alloy is higher than that of pure molybdenum, which reduces the possibility of embrittlement at high temperatures. In high-temperature applications, TZM alloy has higher strength, hardness, creep resistance, and ductility, which can ensure that it will not weaken or become soft.

Therefore, titanium zirconium molybdenum (TZM) alloy is currently a suitable material for manufacturing nozzles.

Thank you for reading our article and we hope it can help you have a better understanding of the Titanium Zirconium Molybdenum (TZM) Alloy for hot runner nozzles. If you want to learn more about Titanium Zirconium Molybdenum (TZM) Alloy or other types of refractory metals and alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as TZM alloy, niobium, molybdenum, tantalum, rhenium, tungsten, titanium, and zirconium at a very competitive price.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.