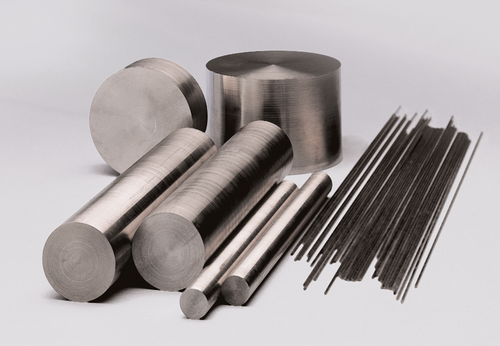

TZM Alloy vs Pure Molybdenum Molybdenum is a transition element with a high melting point, high density (10.23g/cm³), good thermal conductivity, low thermal expansion coefficient, and resistivity, etc. Due to its excellent properties, it is widely used in the steel industry, mold industry, automobile spraying, and other industries. TZM alloy is a common high-temperature alloy in […]

Tags: Advanced Refractory Metals, ARM, molybdenum alloy, molybdenum sheet, molybdenum wire, Powder Metallurgy Technology, pure molybdenum, refractory metals & alloys, titanium, TZM Alloy, Zirconium

Strengthening Mechanism of TZC Alloy TZC alloy, namely molybdenum–titanium–zirconium-carbon alloy, is an aluminum alloy composed of a high content of titanium, zirconium, carbon, and molybdenum, and its general composition is Mo-1.25Ti-0.15Zr-0.15C. Compared with TZM alloy, TZC alloy has better high-temperature resistance and greater strength and can be used as a mold for high-temperature heat processing of […]

Tags: Advanced Refractory Metals, ARM, Molybdenum, Molybdenum Powder, powder metallurgy, powder metallurgy method, titanium, TZC Alloy, TZM Alloy, Zirconium

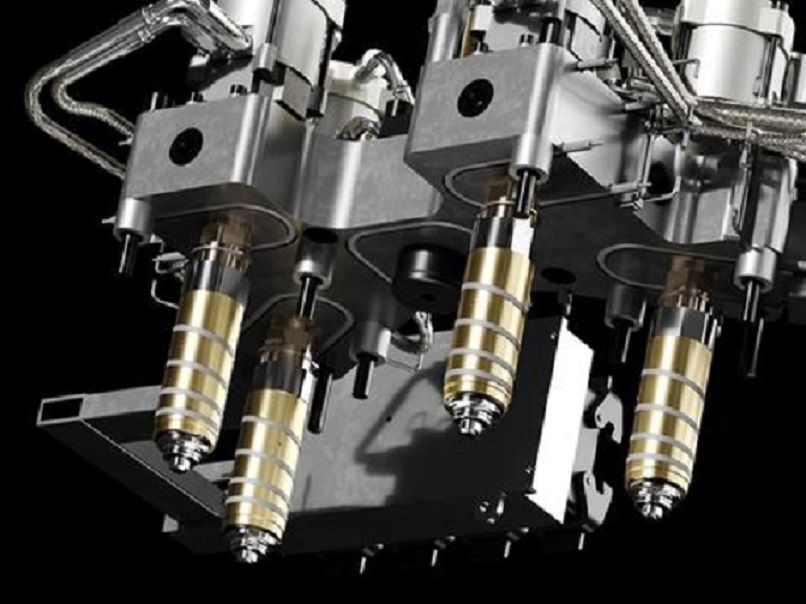

Titanium Zirconium Molybdenum (TZM) Alloy for Hot Runner Nozzles Why use titanium zirconium molybdenum (TZM) alloy for hot runner nozzles? In this article, we will try to find the answer to this question. According to reports, HRSflow is completing the expansion of its 3,000-square-meter factory in San Polo di Piave, Italy. The expansion is designed according […]

Tags: Advanced Refractory Metals, ARM, injection molding process, manufacturer & supplier of refractory metals & alloys, Molybdenum, powder metallurgy, titanium, Titanium-Zirconium-Molybdenum Alloy, types of refractory metals and alloys, TZM, TZM Alloy, Zirconium

TZM Alloy Applications, Properties & Preparation Methods TZM alloy (Titanium-Zirconium-Molybdenum Alloy) is a high-temperature alloy widely used at present. Because of its high melting point, high strength, high elastic modulus, small linear expansion coefficient, low vapor pressure, good electrical and thermal conductivity, strong corrosion resistance, and high-temperature mechanical properties, it is widely used in military, aerospace, […]

Tags: Advanced Refractory Metals, ARM, high-temperature alloy, Molybdenum, powder metallurgy, powder metallurgy method, pure molybdenum, Refractory Metals, titanium, Titanium-Zirconium-Molybdenum Alloy, Tungsten, TZM Alloy, TZM Alloy Applications, TZM Alloy Preparation Methods, TZM Alloy Properties, Zirconium

Applications of Molybdenum and Molybdenum Alloys in the Material Processing Industry Molybdenum and molybdenum alloys have good thermal conductivity, electrical conductivity, low thermal expansion coefficient, high-temperature strength, low vapor pressure, and wear resistance. As a result, they have become important materials for electronic and power equipment manufacturing, metal material processing, glass manufacturing, high-temperature furnace structural parts manufacturing, aerospace, […]

Tags: Advanced Refractory Metals, Applications Of Molybdenum, Applications Of Molybdenum Alloys, Applications of Molybdenum And Molybdenum Alloys, ARM, Molybdenum, Molybdenum Alloys, Molybdenum and Molybdenum Alloys, Molybdenum Powder, refractory alloys, Refractory Metals, Titanium-Zirconium-Molybdenum Alloy, TZM Alloy

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.