Titanium Clad Copper & Its Production Methods

Titanium Clad Copper & Its Production Methods

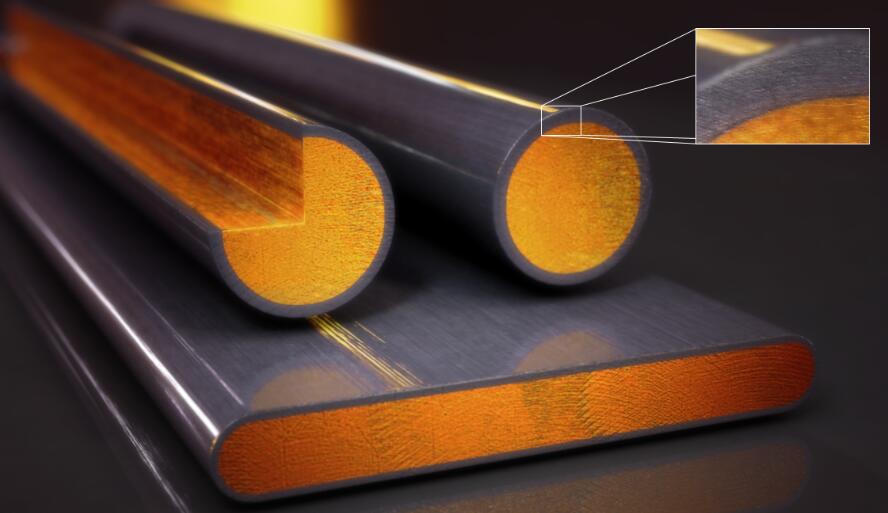

Titanium-clad copper is a metallic material coated with a titanium layer of a certain thickness (generally 1.0~1.2mm) on a copper rod. It is the main component of the metal anode. According to its cross-sectional geometry, it can be divided into round, flat, square, and rectangular titanium-clad copper, and so on.

Titanium Clad Copper

This composite titanium material combines the excellent electrical conductivity of copper and the excellent corrosion resistance of titanium. It can be used as a conductor carrying large currents under relatively corrosive working conditions while ensuring the uniformity of current density and eliminating the pollution of electrolytes caused by the corrosion of copper conductors.

Therefore, it has become the main component of the production of metal anode electrolyzers. Since its invention in the 1960s, it has developed rapidly in various countries around the world.

The Production Methods of the Titanium Clad Coppers

The common production methods of titanium-clad copper mainly include the following: hot extrusion method, hot extrusion and stretching method, explosion method, and explosion and rolling method.

The titanium-clad copper manufactured by hot extrusion has high strength and good composite fastness, and it is not easy to separate titanium and copper. However, the titanium-clad copper produced by this method has a rougher surface and lower bending resistance. After the extruded rod is subjected to a certain cold stretching, the surface roughness is improved, the bending resistance is improved, and the product dimensional accuracy can also be improved. Therefore, the titanium-clad copper currently on the market is mainly produced by hot extrusion and stretching.

The explosive method is to first put a copper rod into a titanium tube, place explosives evenly around the titanium tube, use a detonator to detonate the explosive, and then make the copper rod and the titanium tube form a composite under the action of explosive force. However, this method has low production efficiency and high cost. At present, no one adopts this method in industrial production.

The explosion rolling method is to use a large size titanium tube and copper rod to make billet by explosion method and then the titanium-clad copper is made by the groove rolling method. Compared with the explosive method, this method has higher efficiency and lower cost, but is not suitable for mass production, and can only produce rectangular and flat rods. Whether this method is suitable for the production of titanium-clad copper with other shapes still needs to be further explored.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the titanium-clad copper and its production methods. If you want to know more about titanium, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals across the world. It provides customers with high-quality refractory metals and alloys such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}