Powder Metallurgy Process Overview | Refractory Metals & Alloys

Powder Metallurgy Process Overview

Powder metallurgy is a process of preparing metal powder or using metal powder as raw material, through forming, sintering, and necessary subsequent treatment, to produce various types of products. In this article, let's take a closer look at the powder metallurgy process.

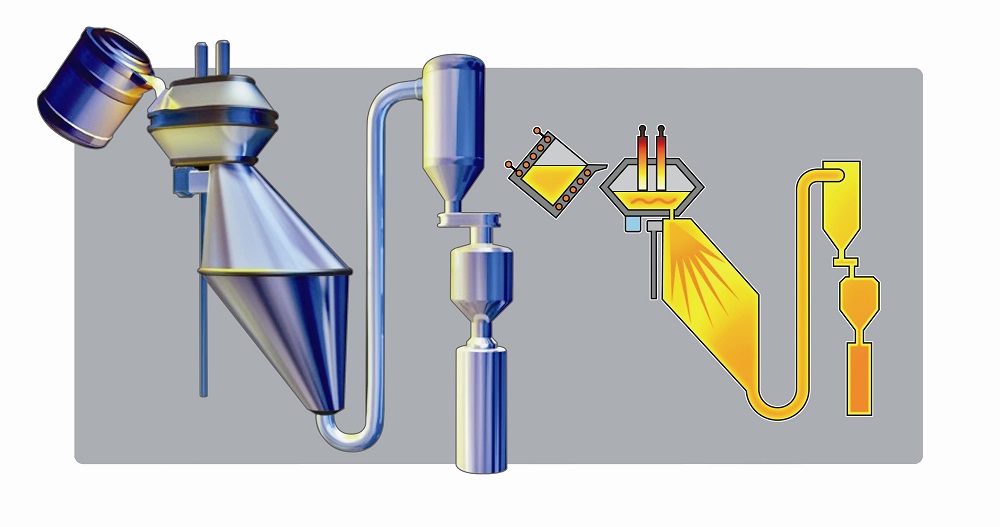

https://youtu.be/_eM49JlmFp0The basic processes of powder metallurgy are:

1. Preparation of raw material powder

The current methods of manufacturing powder can be divided into two categories: mechanical methods and physical-chemical methods. Mechanical crushing and atomization are both mechanical methods. The physical-chemical methods are further divided into electrochemical corrosion method, reduction method, chemical method, reduction-chemical method, vapor deposition method, liquid deposition method, and electrolysis method. Among them, the most widely used methods are reduction, atomization, and electrolysis.

2. Mixing

Mixing is the process of mixing various required powders in a certain proportion and homogenizing them to make a compact. There are three mixing methods: dry, semi-dry, and wet.

3. Forming billets

The purpose is to make a billet of a certain shape and size and have a certain density and hardness. The method of forming billets is basically divided into pressure forming and pressureless forming.

4. Sintering

Sintering is a key process in the powder metallurgy process. After the billet is formed, it is sintered to obtain the required final physical and mechanical properties. Sintering is divided into unit sintering and multi-component sintering. For solid-phase sintering of unit and multi-component, the sintering temperature is lower than the melting point of the metal and alloy used. For multi-component liquid phase sintering, the sintering temperature is generally lower than the melting point of the refractory component and higher than the melting point of the fusible component. In addition to ordinary sintering, there are also special sintering processes such as loose sintering, immersion method, and hot pressing method.

5. Post-processing of powder metallurgy products

After sintering, various methods can be used according to different product requirements, such as finishing, oil immersion, machining, heat treatment, and electroplating.

Powder metallurgy is a branch of metallurgy and materials science. The application range of powder metallurgy products is very wide. From general machinery manufacturing to precision instruments, from hardware tools to large-scale machinery, from the electronics industry to motor manufacturing, from civil industry to military industry, from general technology to cutting-edge high technology, powder metallurgy products can be seen.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the powder metallurgy process. If you want to learn something about refractory powders, refractory metals, and refractory alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory powders, refractory metals, and refractory alloys across the world. It provides customers with high-quality refractory powders, refractory metals, and refractory alloys, like Tungsten, Molybdenum, Tantalum, Rhenium, Titanium, Zirconium, Tungsten Powder, Molybdenum Powder, and Tantalum Powder, etc.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}