Tungsten silver alloy and tungsten copper alloy are both tungsten-based alloys, both of which can be used in aerospace, aviation, electronics, military, defense, and other fields. However, due to their different doping elements, there is a big difference in performance between the two. So in this article, let’s take a closer look at the difference between tungsten silver alloy and tungsten copper alloy.

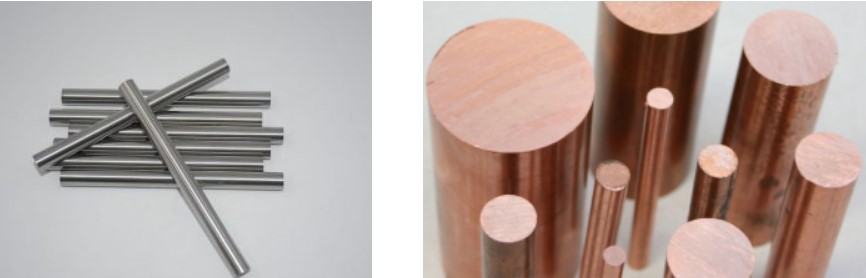

Tungsten Silver Alloy and Tungsten Copper Alloy

Silver-tungsten alloy is a binary alloy composed of silver and tungsten, while tungsten-copper alloy is a binary alloy composed of copper and tungsten.

Tungsten-silver alloys are characterized by high strength, high hardness, resistance to welding, adhesion, welding, arc erosion, and good electrical and thermal conductivity.

Tungsten copper alloys are characterized by high melting point, high hardness, burning resistance, adhesion resistance, high toughness, high-temperature resistance, good plasticity, low volume expansion coefficient, and excellent electrical and thermal conductivity.

The preparation method of tungsten-silver alloy generally uses powder metallurgy, which uses tungsten powder and silver powder as raw materials, and then undergoes forming and sintering steps to produce alloys.

Tungsten copper alloy preparation methods include powder alloy technology, injection molding method, copper oxide powder method, and tungsten frame infiltration method. Among them, the steps of the tungsten frame infiltration method are as follows: first press the tungsten powder into a shape, sinter it into a tungsten skeleton, and then infiltrate copper to obtain the desired product.

Tungsten silver alloy can be used as parts of mechanical equipment such as power switches, relays, circuit breakers, and thermostats.

Tungsten copper alloy can be used as high-temperature components such as plasma cutting machine nozzle, spark electrode, butt welder head, butt welding material, seam welding wheel, electronic packaging material, rocket nozzle throat lining, tail rudder, and so on.

Thank you for reading our article and we hope it can help you better understand the difference between tungsten silver alloy and tungsten copper alloy. If you want to learn more about tungsten alloys or other refractory metals and alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.