Tungsten alloy is an alloy composed of tungsten and other elements. Among metals, tungsten has the highest melting point, good high-temperature strength, and creep resistance, as well as thermal conductivity, electrical conductivity, and electron emission performance. In addition to being widely used in electronics, aerospace, weapons, and other fields, tungsten is also used to manufacture tungsten alloy. In this article, we’ll take a look at the 3 most common types of tungsten alloys.

Tungsten Alloys

Molybdenum-tungsten alloys are molybdenum-based alloys containing 25% and 30% tungsten and have excellent properties to prevent corrosion of molten zinc.

Molybdenum-tungsten alloys can be used at higher temperatures than molybdenum or molybdenum alloys. For example, when the molybdenum-tungsten alloy is used as the electrode, spout, and thimble component in the furnace for producing high melting point refractory ceramic fiber, its service life is much longer than that of pure metal molybdenum products.

Molybdenum Tungsten Alloys

Molybdenum-tungsten alloy has higher corrosion resistance to zinc liquid than pure metal molybdenum, and it is mostly used for zinc liquid temperature measuring tubes, zinc liquid pump rotors, and some corrosion-resistant parts of the zinc smelting furnace.

Molybdenum-tungsten alloys can also be used for solid rocket motor gas rudders and guard plates due to their high melting point, good ablation resistance, and good flame erosion resistance against solid particles.

Niobium-tungsten alloy is a niobium alloy formed by adding a certain amount of tungsten and other elements based on niobium. Tungsten and niobium form an infinite solid solution.

Niobium-tungsten alloy has good high-temperature strength and good room-temperature plasticity and can be made into various processed materials and parts by conventional forming processing technology. It is mainly used for space shuttle skin, nuclear reactor engineering, jet engine parts, and heat radiation screens and ducts for space power generation systems.

The Application of Niobium Tungsten Alloys

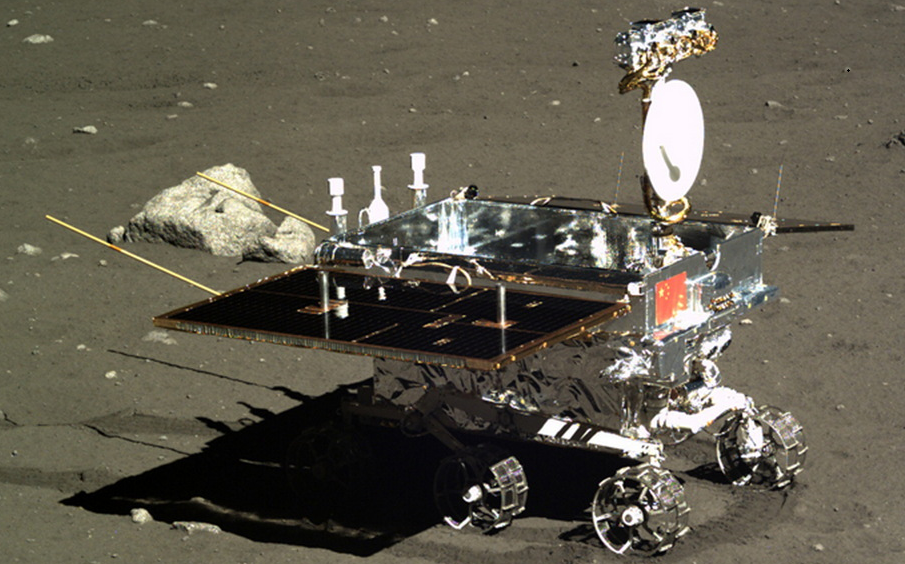

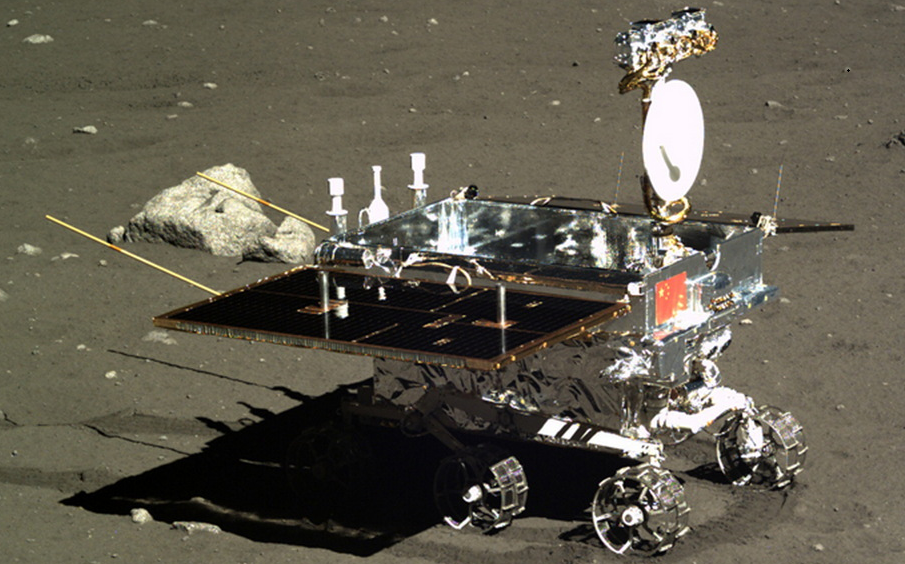

Part of the supporting facilities of Chang’e-3 uses niobium-tungsten alloy and coating materials. Niobium-tungsten alloy and coating materials are mainly used in the launch tail shield to protect against the effects of high temperature during launch, but the specific amount is very small.

Tungsten carbide is the most common and most important form of tungsten alloy. Unlike the previous tungsten alloys, its main components are tungsten, carbon, and cobalt, so it is also often called a tungsten-cobalt alloy.

Tungsten carbide has high hardness, strength, wear resistance, and corrosion resistance, and is known as “industrial teeth”. It is used to manufacture cutting tools, knives, cobalt tools, and wear-resistant parts.

It is widely used in military industry, aerospace, mechanical processing, metallurgy, petroleum drilling, mining tools, electronic communications, construction, and other fields, with the development of downstream industries, the demand for cemented carbide market continues to increase.

Moreover, the future development of high-tech weapons and equipment, the advancement of cutting-edge science and technology, and the rapid development of nuclear energy will vigorously increase the demand for high-tech content, high-quality, high-stability tungsten carbide products.

Thank you for reading our article and we hope it can be helpful to you. If you want to know more about the types of tungsten alloy and other refractory metals, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metal products such as tungsten, molybdenum, tantalum, rhenium, titanium, zirconium, etc.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.