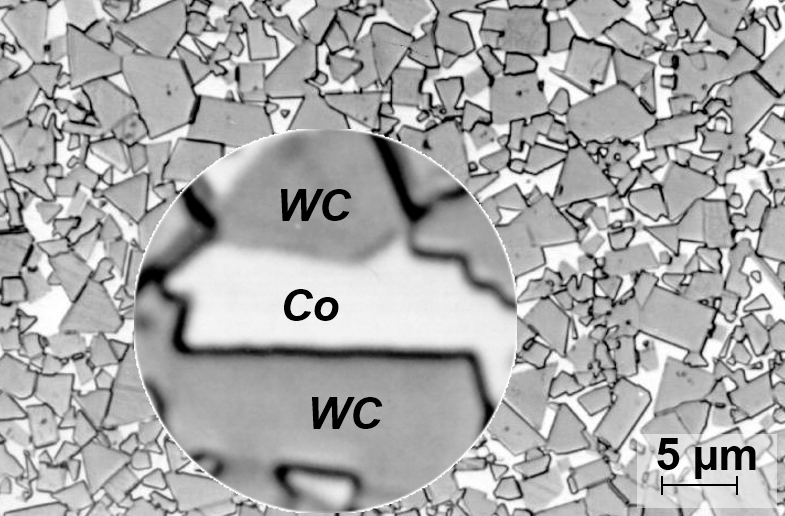

Magnetic Saturation and Coercivity of WC-Co Hard Alloys WC-Co hard alloy is an alloy with tungsten and cobalt as the main components. According to the cobalt content, WC-Co hard alloy can be divided into three types: high cobalt (20%~30%), medium cobalt (10%~15%), and low cobalt (3%~8%). This alloy can be used as a tool to process cast […]

Tags: Advanced Refractory Metals, ARM, Cemented Carbide, cobalt, Coercivity of WC-Co Hard Alloys, Magnetic Saturation of WC-Co Hard Alloys, manufacturer of refractory metals & alloys, supplier of refractory metals & alloys, Titanium alloys, Tungsten, Tungsten alloys, WC-Co Hard Alloys

Cemented Carbide for Watch Chains For the new generation of watch chains, the reason why cemented carbide should be used as the core raw material is that it has better wear resistance and the product is not prone to deformation under any circumstances. In this article, let’s take a quick look at the cemented carbide […]

Tags: Advanced Refractory Metals, ARM, Cemented Carbide, cobalt powder, manufacturer of refractory metals & alloys, refractory alloys, Refractory Metals, supplier of refractory metals & alloys, tungsten carbide, tungsten product

The Most Refractory Metal Tungsten Tungsten is widely used in our daily life. For example, the filament inside a light bulb is mainly made of tungsten. When the lamp is lit, the temperature of the filament is as high as 3000 ℃ or more. At such a high temperature, most metals will melt into liquid or even […]

Tags: Advanced Refractory Metals, ARM, Cemented Carbide, high-quality refractory metals, Most Refractory Metal, most refractory metal tungsten, Refractory Metal Tungsten, The Most Refractory Metal Tungsten, Tungsten, tungsten chromium cobalt alloy, tungsten metal, Tungsten Powder, tungsten steel, tungsten titanium alloy, tungsten wire, Use of Tungsten

Application of Tungsten And Tungsten Alloys Tungsten, which has an atomic number of 74 in the periodic table, is a VIB group metal. It has a density of 19.35 g/cm3 that is close to gold, with a melting point of 3,422 ℃ and a boiling point of 5,927 ℃. In this article, we’ll take a look […]

Tags: Advanced Refractory Metals, Application Of Tungsten, Application Of Tungsten Alloys, Cemented Carbide, Doped Tungsten Alloy, Heat-Resisting Alloy, Metal with High Melting Point, powder metallurgy, Refractory Metals, Tungsten, tungsten alloy, tungsten carbide, Tungsten Copper Alloy, Tungsten Heavy Alloy, tungsten rod, tungsten steel, tungsten wire

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.