Magnetic Saturation and Coercivity of WC-Co Hard Alloys

Magnetic Saturation and Coercivity of WC-Co Hard Alloys

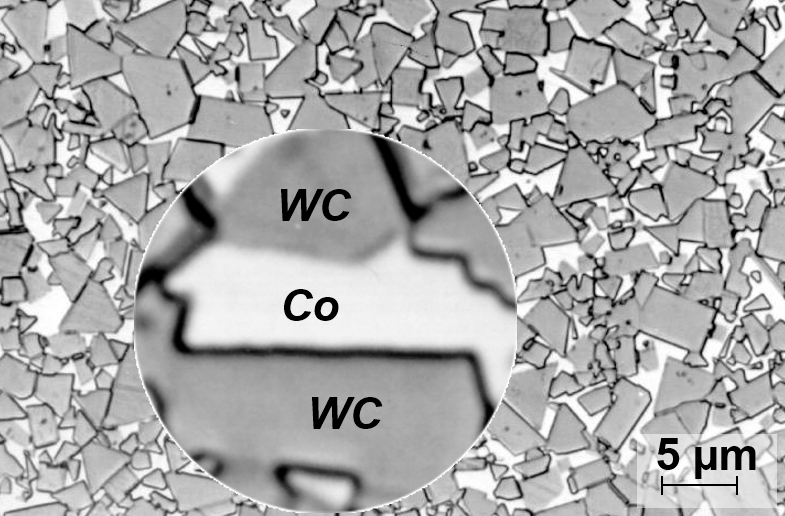

WC-Co hard alloy is an alloy with tungsten and cobalt as the main components. According to the cobalt content, WC-Co hard alloy can be divided into three types: high cobalt (20%~30%), medium cobalt (10%~15%), and low cobalt (3%~8%). This alloy can be used as a tool to process cast iron, non-ferrous metals, non-metals, heat-resistant alloys, titanium alloys, stainless steel, etc., and can also be used as extension dies, wear-resistant parts, stamping dies, and drill bits. In this article, let's take a closer look at the magnetic saturation and coercivity of WC-Co hard alloys.

Magnetic Saturation and Coercivity of WC-Co Hard Alloys

1. The Magnetic Saturation of WC-Co Hard Alloys

With the increase of the external magnetic field, the magnetic induction intensity of the tungsten-cobalt alloy also increases. When the magnetic field intensity reaches a certain value, the magnetic induction intensity does not increase anymore, that is, the tungsten-cobalt alloy has reached magnetic saturation.

The magnetic saturation value of the tungsten-cobalt alloy is only related to its cobalt content and has nothing to do with the grain size of the tungsten carbide phase in the tungsten-cobalt alloy. Therefore, magnetic saturation can be used for non-destructive composition inspection of tungsten-cobalt alloys, or to identify the presence of non-magnetic ηl phases in alloys of known composition.

2. The Coercivity of WC-Co Hard Alloys

The coercive force of tungsten-cobalt alloy is because the binder phase in the cemented carbide is a ferromagnetic substance so that the tungsten-cobalt alloy has certain magnetic properties. Coercive force can be used to control the structure of the tungsten-cobalt alloy. The coercivity of tungsten-cobalt alloy is mainly related to the diamond content and its dispersion, and it increases with the decrease of the cobalt content. When the amount of cobalt is constant since the degree of dispersion of the cobalt phase increases as the tungsten carbide grains become finer, the coercive force also increases, and vice versa.

Therefore, under the same other conditions, the coercive force can be used as an indirect measure of the size of the tungsten carbide grains in the alloy. In the alloy with a normal structure, as the carbon content decreases, the tungsten content in the drill phase increases, which makes the cobalt phase strengthened, and the coercive force will increase accordingly. Therefore, the greater the cooling rate during sintering, the greater the coercive force.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the magnetic saturation and coercivity of WC-Co hard alloys. If you want to learn more about tungsten alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}