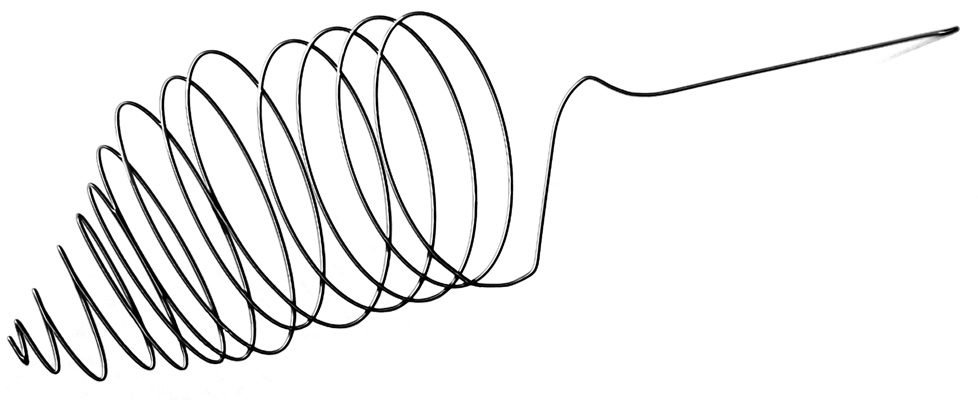

Nickel-titanium alloy, also known as nitinol, is a binary alloy made up of nickel and titanium, these two elements are roughly equal in atomic percentage (Nitinol 55 and Nitinol 60 are very common). There are two different crystal structures in nickel-titanium alloy due to the change of temperature and mechanical stress, which are called austenitic and martensitic.

Nickel Titanium Alloy

The austenitic phase was known as the parent phase in the nickel-titanium alloy, which is a crystalline phase of high-temperature alloy, and it would transform gradually into the martensite phase (child phase) at a lower temperature.

There are four temperatures in the process of the martensite and austenite phases transforming into each other:

As: the temperature of the martensite began to transform to austenite in the process of heating up;

Af: the temperature of martensite accomplished the transformation to austenite in the process of heating up;

Ms: the temperature of the austenite began to transform to martensite during the process of cooling;

Mf: the temperature of the austenite accomplished the transformation to martensite during the process of cooling.

There is a thermal hysteresis in the transformation of nickel-titanium alloy, so As is not equal to Mf and Af is not equal to Ms.

Shape memory refers to that the material will restore its shape automatically in the parent phase when the parent phase in a certain shape cooled from Af temperature above to Mf temperature below and forms martensite fully, later the martensite deformed under Mf temperature and then heated to Af temperature below along with the inverse transformation.

Actually, the shape memory effect is a thermal-induced phase transformation process of the nickel-titanium alloy, which refers to the deformation ability of Nitinol at a temperature, and then back to the restorable shape under the temperature that is higher than its “transition temperature”.

Superelastic refers to the phenomenon that the sample produces a greater variable strain than the elastic limit under an external force of strain which can be restored automatically when unload.

In the parent phase state, the martensite phase transformed due to the applied stress, thus the alloy showed different mechanics behavior from the ordinary material, the elastic limit of which is far greater than ordinary materials and no longer complies with Hooke’s law. Compared with the shape memory properties, the superelastic has no hot in it.

Thank you for reading our article and we hope you enjoyed it. If you want to know more about Nickel-titanium Alloy and other refractory metals, you can visit Advanced Refractory Metals for more information. We provide our customers with high-quality refractory metals at a very competitive price.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.