What Are the Uses of Tantalum and Its Alloys?

What Are the Uses of Tantalum and Its Alloys?

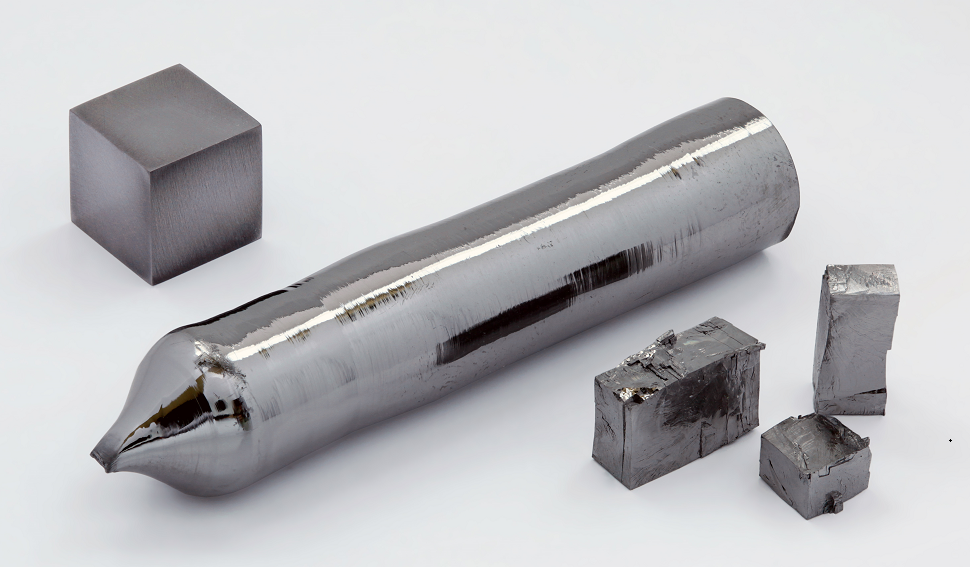

Tantalum is the third most refractory metal, with a melting point of 2980℃, only after tungsten and rhenium. Besides, tantalum also has other excellent properties like low vapor pressure, good cold workability, high chemical stability, strong resistance to liquid metal corrosion, and a large dielectric constant of the surface oxide film. Therefore, it has already been widely used in the industry and our everyday life. In this article, let's take a look at what are the uses of tantalum and tantalum alloys.

What Are the Uses of Tantalum?

The Uses of Tantalum & Tantalum Alloys

1. The Uses of Tantalum in the Field of Capacitors

50%-70% of the world's tantalum is used to make tantalum capacitors in the form of capacitor-grade tantalum powder and tantalum wire.

Since the surface of tantalum can form a dense and stable oxide film with high dielectric strength, it is easy to accurately and conveniently control the anodizing process of the capacitor. At the same time, the tantalum powder sintered block can obtain a large surface area in a small volume, so the tantalum capacitor has high capacitance, small leakage current, low equivalent series resistance, long service life, and excellent comprehensive performance.

Tantalum capacitors are widely used in communications (switches, mobile phones, pagers, fax machines, etc.), computers, automobiles, household and office appliances, instrumentation, aerospace, defense, military industries, and other industrial and scientific sectors.

2. The Uses of Tantalum in the Chemical Industry

In the chemical industry, tantalum can be used to replace stainless steel in equipment for making various inorganic acids, and the life of the equipment can be increased by dozens of times compared with the use of stainless steel. And tantalum oxide is used to manufacture advanced optical glass and catalysts.

3. The Uses of Tantalum in the Field of Cemented Carbide

In the field of cemented carbide, tantalum carbide can be used to manufacture cemented carbide. Adding a certain amount of tantalum carbide to the cemented carbide containing titanium carbide can not only improve the strength of the cemented carbide at room temperature but more importantly, it can increase the flexural strength of the cemented carbide at 1200°C.

In addition, the tantalum carbide-containing cemented carbide has good weldability and is less prone to cracking during sharpening, which improves the performance of the cemented carbide. The cemented carbide inserts for milling should contain more tantalum carbide so that the strength of the tip is high, and it has better adaptability to the impact and temperature changes during intermittent cutting.

4. The Uses of Tantalum in the Chemical, Electronic, and Electrical Industries

In the chemical, electronic, and electrical industries, tantalum can be used to undertake tasks that were previously undertaken by the precious metal platinum, which greatly reduces the cost.

5. The Uses of Tantalum in the Field of Electronics

In the field of electronics, tantalum is used to make electron emission tubes and high-power electron tube parts.

6. The Uses of Tantalum & Its Alloys in the Aerospace and Military Fields

In the aerospace and military fields, tantalum tungsten, tantalum tungsten hafnium, and tantalum hafnium alloy are used as heat-resistant high-strength materials for rockets, missiles, and jet engines, as well as parts for control and regulation equipment.

7. The Uses of Tantalum & Its Alloys in the Field of Metallurgy

In the field of metallurgy, tantalum, and its alloys can be used as heat shields, heaters, and heat sinks in high-temperature vacuum furnaces because it has a high melting point and is easy to process and form.

8. The Uses of Tantalum & Its Alloys in the Field of Healthcare

In the field of healthcare, tantalum and its alloys can be used as a material for orthopedics and surgery. For example, tantalum strips can be used to replace bones in the human body, and muscles can also grow on the tantalum strips.

9. The Uses of Tantalum & Its Alloys in the Atomic Energy Industry

In the atomic energy industry, tantalum borides, silicides, and nitrides, and their alloys can be used as heat-release elements and liquid metal sheath materials.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of what are the uses of tantalum and its alloys. If you want to know more about tantalum and other refractory metals, we would like to recommend visiting Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a top manufacturer & supplier of refractory metal products across the world, providing customers with high-quality refractory metals such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}