Factors Affecting the Performance of Tungsten Powder

Factors Affecting the Performance of Tungsten Powder

As we all know, there are many factors that affect the performance of tungsten powder, but the main factors are nothing more than the production process of the tungsten powder, the properties, and characteristics of the raw materials used, and so on. Generally, there is more research on the effect of the reduction process on the performance of tungsten powder, including reduction temperature, boat pushing speed, boat loading and method, and reducing atmosphere.

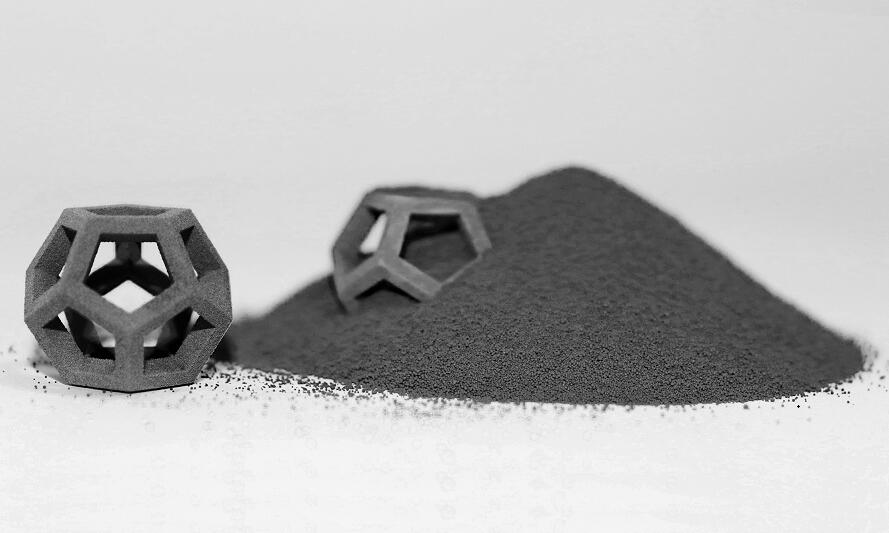

Performance of Tungsten Powder

However, in the process of production and research, researchers found that the properties of different raw materials used will also have a great influence on the performance of tungsten powder. Next, let's take a look at the influence of raw materials used (WO3, WO2.98, WO2.72, and WO2) on the properties of tungsten powder.

(1). The difference in characteristics of different raw materials directly determines the particle size and composition of the tungsten powder, the physical properties such as compatibility and moldability, the content of impurity elements, and the morphology and structure of the tungsten powder. In actual production, raw materials should be selected according to the requirements of tungsten powder when selecting raw materials, which helps ensure product quality and achieve good economic benefits.

(2). The oxygen content in the raw materials is positively correlated with the Fs of the tungsten powder. The purple WO2.72 with lower oxygen content should be selected as the raw material for the production of ultrafine tungsten powder. For the production of coarser tungsten powder, yellow WO3 and blue WO2.98 with high oxygen content should be selected as raw materials.

(3). The tighter the particle structure of the raw material, the slower the reduction rate, the coarser the tungsten powder produced, and the wider the particle size distribution. In order to produce tungsten powder with high concentration, it is advisable to choose oxide raw materials with single-phase composition, loose internal structure, and uniform particle size.

(4). For the production of tungsten products with special performance requirements, it is better to choose specially treated tungsten oxide or purple tungsten oxide (WO2.72) as raw materials.

Pure tungsten powder can be made into materials such as wires, rods, tubes, plates, and other products with certain shapes. In addition, tungsten powder mixed with other metal powders can also be made into various tungsten alloys, such as tungsten-molybdenum alloy, tungsten rhenium alloy, tungsten copper alloy, and high-density tungsten alloy.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the factors affecting the performance of tungsten powder. If you want to know more about tungsten power and other refractory metals and alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as molybdenum, tantalum, rhenium, tungsten, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}