People in the wire-cutting industry know that molybdenum wire breakage is often occurring in the wire-cutting process. So why do molybdenum wires always break in the wire cutting? In this article, we will try to find out the reasons why molybdenum wires break in the wire cutting.

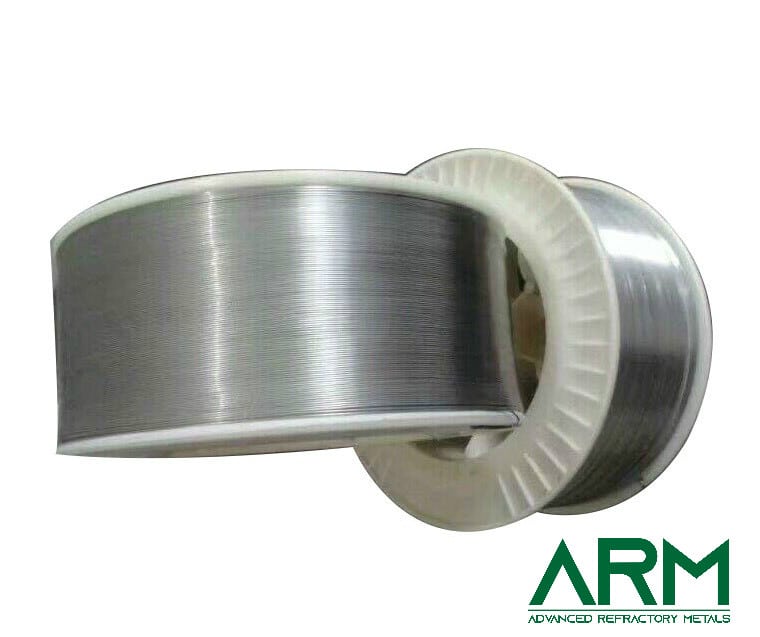

Molybdenum Wires

In normal conditions, the diameter loss of molybdenum wire per cutting l0000mm2 is approximately 0.001~0.02mm. Therefore, molybdenum wires should be replaced in time after losing too much or the service life is expired.

The tension of the new molybdenum wire should be adjusted first. If the molybdenum wire is too tight, it is easy to break the wire; if the molybdenum wire is too loose, then the key molybdenum wire is elongated and easily shorted back. Therefore, the tension of the molybdenum wire should be regularly adjusted to the appropriate size.

Wire Cutting

The conductive block is usually pressed or raised molybdenum wire. Because the molybdenum wire runs for a long time to contact the conductive block, the conductive block will have grooves, which will break the molybdenum wire. Therefore, the conductive block should be rotated to a certain angle periodically, or it should be replaced directly.

The molybdenum wire is guided by the guide wheel, so the precision of the guide wheel affects the operation of the molybdenum wire. The bearing which supports the guide wheel influences the axial and radial runout of the guide wheel and thus affects the stability of discharge machining of molybdenum wire.

Molybdenum Wires

The selection of technology parameters has a great influence on molybdenum wire loss, and excessive loss will accelerate the breakage. The technology parameters should be selected according to the specific parts, such as the material of the parts, the thickness of the parts, and the accuracy of the parts. The parameter is usually selected by the operator by experience, or by some intelligent technology. For example, the BP algorithm in the neural network is optimized to select cutting parameters.

Thank you for reading our article and we hope you’ve enjoyed it. If you want to know more about molybdenum wires and other refractory metals, we advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, America, Advanced Refractory Metals (ARM) supplies people with high-quality molybdenum products such as molybdenum wire, molybdenum strips, molybdenum tubes, etc. all over the world. Please visit https://www.refractorymetal.org for more information.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.