Common Uses of Rhodium Thermocouple Wire

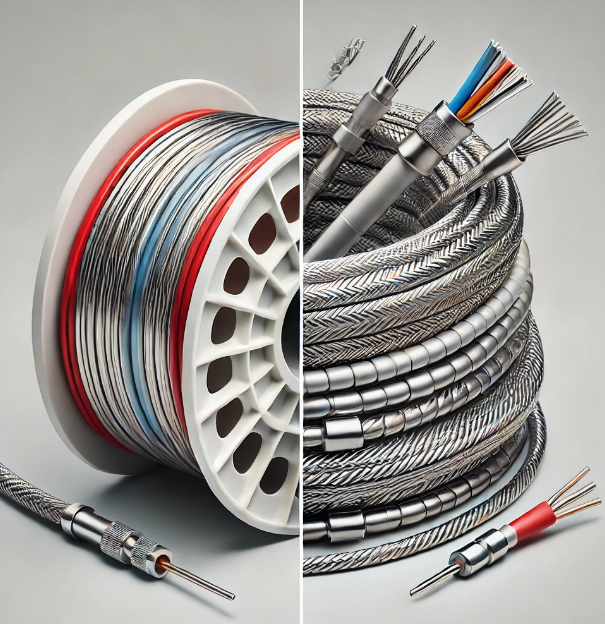

What Is Rhodium Thermocouple Wire?

Rhodium thermocouple wire is a specialized type of wire used to create thermocouples for precise temperature measurement in extreme environments. Thermocouples consist of two dissimilar metals joined at one end, and they generate a voltage that correlates to temperature, allowing for accurate measurement. Rhodium, when combined with platinum in thermocouple wires, enables high-temperature tolerance and superior resistance to oxidation and corrosion.

Rhodium thermocouples, particularly those made with platinum-rhodium alloys, are widely used in applications where temperatures can exceed 1600°C, offering high accuracy and long-term stability. These thermocouples are especially vital in industries where processes require tight thermal control and reliability.

Types of Rhodium Thermocouple Wire

There are three primary types of rhodium thermocouples, categorized based on their composition and temperature range:

- Type B (Platinum-30% Rhodium / Platinum-6% Rhodium)

Type B thermocouples are designed for extremely high-temperature applications, with the capability to measure temperatures up to 1800°C. They are commonly used in environments where stability and accuracy are essential at elevated temperatures, such as in glass manufacturing and metal processing.

- Type S (Platinum-10% Rhodium / Platinum)

Type S thermocouples have a slightly lower temperature range, up to 1600°C, and are often found in applications that require moderate high-temperature stability. These thermocouples are typically used in industries like pharmaceuticals, glass, and laboratory research.

- Type R (Platinum-13% Rhodium / Platinum)

Similar to Type S, Type R thermocouples are used in applications requiring stable measurements at temperatures up to 1600°C. They are common in glass manufacturing, semiconductor processing, and other environments where consistent temperature measurement is critical.

| Thermocouple Type | Composition | Temperature Range | Common Applications |

| Type B | Pt-30% Rh / Pt -6% Rh | Up to 1800°C | Glass manufacturing, metal processing |

| Type S | Pt-10% Rh / Pt | Up to 1600°C | Pharmaceuticals, glass, laboratory research |

| Type R | Pt-13% Rh / Pt | Up to 1600°C |

Glass manufacturing, semiconductor processing |

Advanced Refractory Metals (ARM) is a trusted supplier of high-quality Platinum-Rhodium Thermocouple Wires. We offer Types R, S, and B for reliable performance in industrial applications like furnaces, kilns, and jet engines. Customized solutions to meet specific needs are also available. Send us an inquiry if you are interested.

Why Rhodium Thermocouple Wire?

Rhodium thermocouple wire offers several distinct advantages over other thermocouple materials, making it the preferred choice for high-temperature applications:

- High-Temperature Stability

Rhodium thermocouples can reliably measure temperatures in the range of 1200°C to 1800°C, making them ideal for extreme environments. Their stability at these temperatures ensures that measurements remain accurate and reliable over time.

- Oxidation and Corrosion Resistance

Rhodium’s inherent resistance to oxidation and corrosion enables these thermocouples to operate in harsh environments, such as molten glass or metal processing. This resistance enhances the longevity and durability of the thermocouples, reducing the frequency of replacement and maintenance.

- Precision and Accuracy

Rhodium thermocouples provide precise temperature readings, which are critical in industries where even slight temperature fluctuations can impact the quality of products or the safety of processes. The accuracy of rhodium thermocouples makes them indispensable in industries like aerospace and nuclear power.

- Longevity and Durability

Due to their resistance to wear, oxidation, and high temperatures, rhodium thermocouples have a long service life. This makes them cost-effective for applications requiring long-term reliability in extreme conditions, reducing downtime caused by equipment failure.

Common Uses of Rhodium Thermocouple Wire

1. Aerospace Industry

In aerospace, precision and reliability are paramount, particularly in high-temperature environments like jet engines and turbines. Rhodium thermocouples are used to monitor exhaust gas temperatures and turbine components, ensuring the safety and efficiency of aircraft. The thermocouples help provide crucial data during testing and operation, allowing engineers to fine-tune performance and prevent overheating.

2. Glass Manufacturing

Glass production involves melting materials at temperatures that exceed 1500°C. Rhodium thermocouples are employed in furnaces to monitor the molten glass temperature, ensuring consistency in the product. Accurate temperature control is critical in avoiding defects such as bubbles or uneven glass, making these thermocouples essential in the glass industry.

3. Metal Processing and Foundries

Rhodium thermocouples are vital in the processing of metals like steel, titanium, and nickel alloys. In foundries and metal production facilities, these thermocouples measure temperatures in furnaces and kilns to ensure proper melting and casting processes. Their high-temperature capabilities are essential for creating strong, high-quality metal components.

4. Semiconductor Manufacturing

The semiconductor industry relies on precise temperature control during various processes, such as crystal growth and chemical vapor deposition (CVD). Rhodium thermocouples are used to monitor these processes, ensuring that the correct temperature is maintained, which is crucial for the proper formation of semiconductor materials.

5. Nuclear Power Plants

Rhodium thermocouples are also used in nuclear reactors to monitor the temperature of the reactor core and other components. These thermocouples ensure that the reactor operates within safe temperature ranges, preventing overheating and ensuring efficient energy production. Their reliability under extreme conditions makes them an ideal choice for such critical applications.

6. Laboratories and Research Facilities

In laboratories, especially those involved in materials science and high-temperature research, rhodium thermocouples are used in experimental setups that require accurate temperature monitoring. These thermocouples are used in high-temperature furnaces for testing the properties of advanced materials like ceramics and superalloys, as well as in other research requiring precise temperature control.

Conclusion

Rhodium thermocouple wire plays a critical role in high temperatures and other extreme conditions. Whether in aerospace, glass manufacturing, metal processing, semiconductor production, or nuclear power, these thermocouples provide the high-temperature stability, corrosion resistance, and durability necessary for ensuring the safety, efficiency, and quality of various processes. As technology continues to advance, the demand for accurate temperature measurement in extreme environments will only grow, further solidifying the importance of rhodium thermocouples across multiple sectors.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}