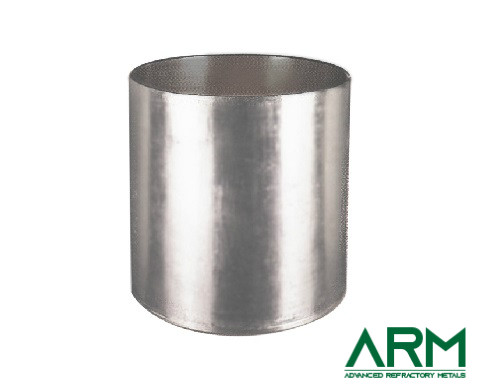

Iridium crucibles provided by Advanced Refractory Metals (ARM) are made from raw Iridium material with high purity & no defect by using Plasma Double Melting process. Our hot forging machine and rolling mills enable us to produce high-density iridium plate good for making crucibles.

ARM is a leading supplier of iridium products. We offer competitive pricing and great lead times on all our materials, and we're capable of supplying custom materials per any specs/drawings you provide us with.

|

Linear Formula |

Ir |

|

CAS |

7439-88-5 |

|

PubChem CID |

23924 |

|

MDL Number |

MFCD00011062 |

|

EC No. |

231-095-9 |

|

InchI Identifier |

InChI=1S/Ir |

|

InchI Key |

GKOZUEZYRPOHIO-UHFFFAOYSA-N |

Typical Chemical Analysis

| Ir(%) | 99.96% | ||

| Impurities(ppM): | |||

| Ag | 2 | Os | 3 |

| Au | 3 | Pt | 18 |

| Be | – | Sb | 11 |

| Ca | 6 | Sn | 3 |

| Cr | 3 | Zr | 2 |

| Mg | 2 | As | <2> |

| Ni | 3 | Co | <2> |

| Pd | 22 | Cu | 3 |

| Ru | 15 | Mo | <2> |

| Si | 4 | Pb | 3 |

| Zn | 21 | Rh | 42 |

| Al | 7 | Se | 5 |

| B | <2> | Te | <2> |

| Bi | 2 | ||

| Cd | <2> | ||

| Cs | – | ||

| Mn | <2> |

Iridium crucibles are mainly used for a particular way of single crystal growth, called the Czochralski method (CZ method).

The remarkable characteristics of Iridium are high melting point up to more than 2,400 degrees C and high corrosion resistivity not to be dissolved even by nitro-hydrochloric acid under normal temperature, and those are the reasons why Iridium is necessary for growing crystal of high melting point. CZ method is the way of crystal growth by touching seed crystal to melted raw materials of the crystal in the crucible, and then rotating and pulling up very slowly. LT (Lithium Tantalite) for noise filter of cell phone and Sapphire for LED substrate are representative crystals made with Iridium Crucibles.

Our Iridium Crucibles are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

Submit your review | |

I bought it for a science experiment and I was not disappointed.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.