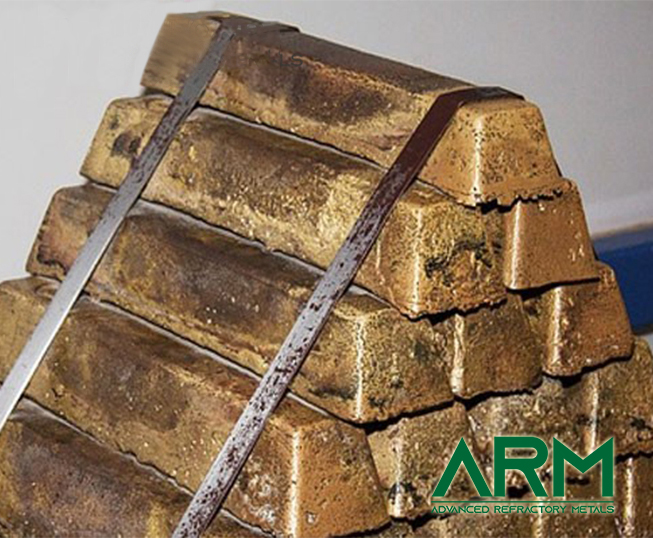

CM2837 Nickel Aluminum Bronze (AMS 4640)

Nickel Aluminum Bronzes have been adapted with time to optimize performance and can provide a combination of properties that can offer an economic alternative to other types of alloy systems.

| Catalog No. | CM2837 |

|---|---|

| Molecular Formula | Cu-Al-Ni-Fe |

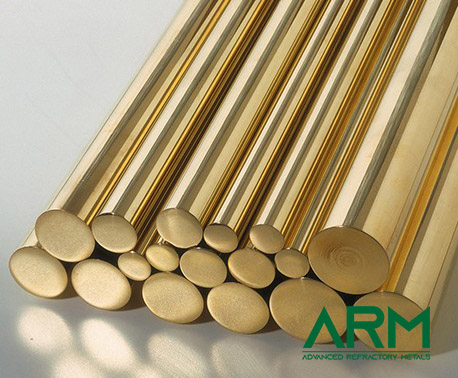

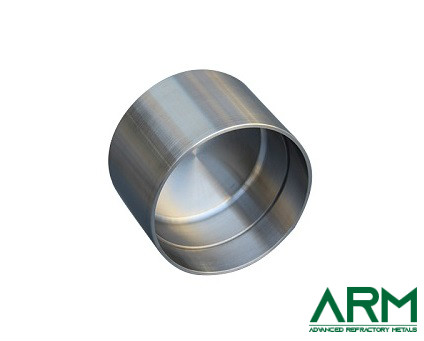

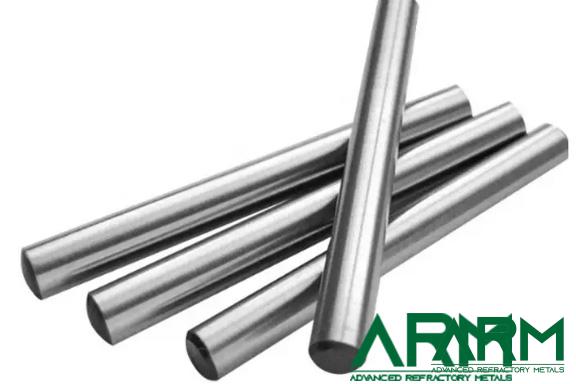

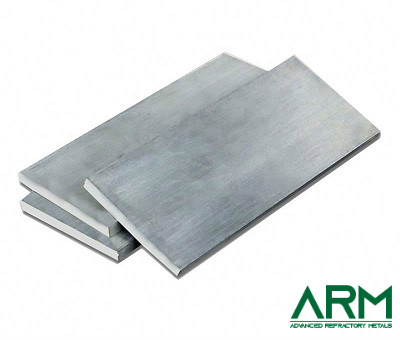

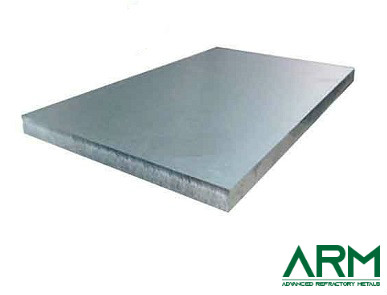

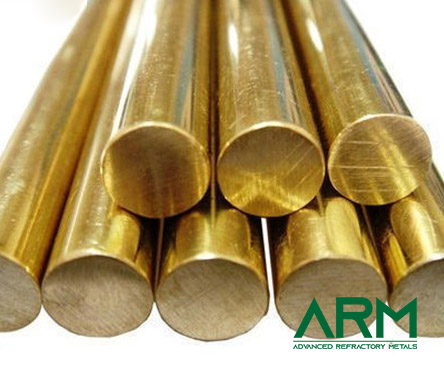

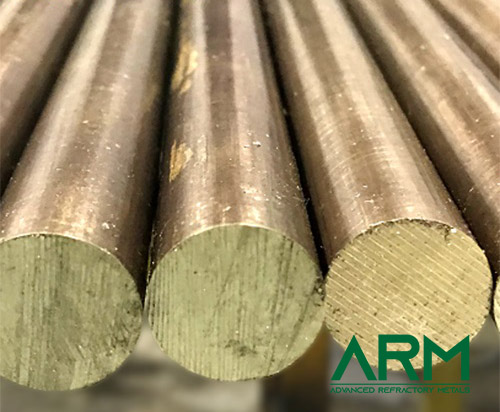

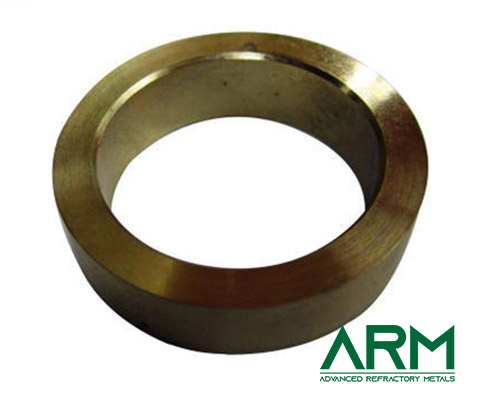

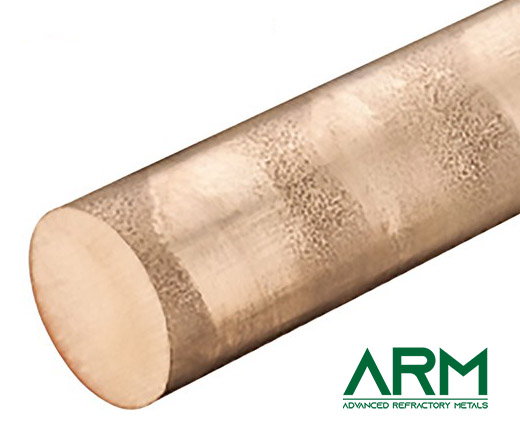

| Appearance | Light Bronze Bar/Plate |

| Hardness | 180-240 |

Nickel Aluminum Bronze (AMS 4640) Description

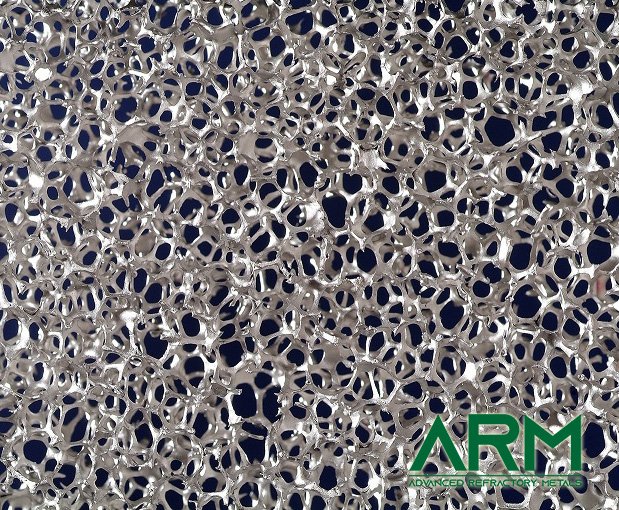

Nickel Aluminum Bronzes have been adapted with time to optimize performance and can provide a combination of properties that can offer an economic alternative to other types of alloy systems. Nickel Aluminum Bronzes are available in both cast and wrought product forms and have a unique combination of properties such as excellent wear and galling resistance, high corrosion resistance, high strength, density (10% lighter than steel), low magnetic permeability (of

Nickel Aluminum Bronze (AMS 4640) Specifications

| Size (Solid Bar) | 3/8” - 15” diameter |

| Size (Hex & Square Bar) | Customizable |

| Size (Plate) | Cut to size, up to 6” thick |

| Centrifugal |

ASTM B-150-12, ASTM B-124, ASTM B-171, ASTM B-283, AMS 4640 G, SAE J463, QQ-C-465 B, ASME SB150 |

| Continuous |

AMS 4880 |

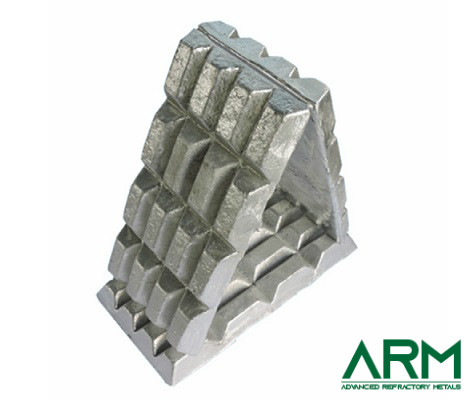

| Ingot | ASTM B30 |

| Precision | ASTM B806 |

| Sand | ASTM B148, B763, SAE J461, J462 |

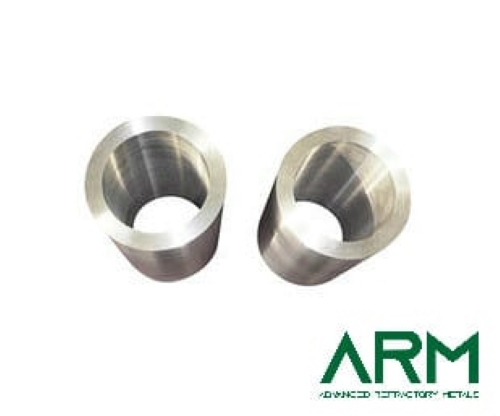

Nickel Aluminum Bronze (AMS 4640) Applications

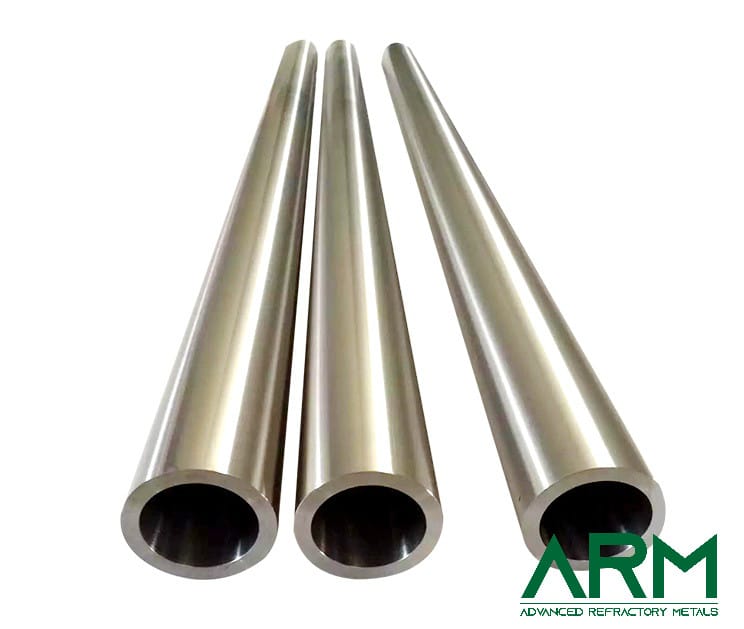

There is a large market for Nickel Aluminum Bronze (AMS 4640) in naval applications, particularly for the submarine fleets of the world. The main applications are in seawater piping and valve systems, weapons handling, flexible couplings, sonar equipment, seawater external hatches, hydraulic valves and bearings, fasteners and sealing flanges, low noise propellers, propulsion equipment as well as periscope assemblies. These applications make use of some of the important properties of nickel aluminum bronzes: good corrosion resistance, non-sparking, wear resistance, high strength, and good impact properties.

The alloys also exhibit good anti-damping properties, twice that of steel, which is important for submarines in suppressing sound for silent operations. Non-sparking and wear resistance become particularly important in weapons' handling systems. The various grades with lower iron and nickel contents can be manufactured with magnetic permeability below 1.03 µ.

Nickel Aluminum Bronze (AMS 4640) Packaging

Our Nickel Aluminum Bronze (AMS 4640) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-