Descriptions of Tantalum (Ta)

Tantalum is a ductile metal. Tantalum has excellent corrosion resistance to most chemicals except hydrofluoric acid. Tantalum metal has a melting point exceeded only by tungsten & rhenium. The melting point of tantalum is approximately 3017 degrees Celsius. Tantalum’s main end uses are in capacitors, vacuum furnaces, chemical process equipment, and aircraft parts.

Advanced Refractory Metals is a leading supplier of tantalum products. We offer low pricing and great lead times on all our materials, and we're capable of supplying custom materials per any specs/drawings you provide us with.

About Tantalum (Ta)

- Symbol: Ta

- Atomic Number: 73

- Atomic Weight: 180.95

- Element Category: Refractory Metal

Tantalum is a dense, blue-gray refractory metal known for its exceptional corrosion resistance, high melting point, and excellent biocompatibility. It forms a stable oxide layer that protects it from nearly all acids, even at elevated temperatures. Because of its remarkable stability, tantalum is essential in industries that demand performance under extreme chemical, thermal, and mechanical stress.

Tantalum Product Categories

Tantalum Metals

Forms Available:

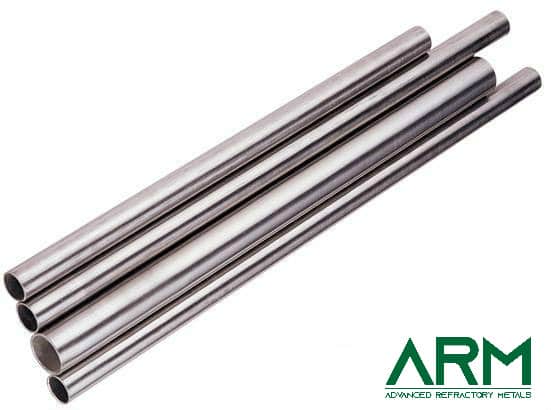

Sheet, Plate, Foil, Strip, Rod, Bar, Wire, Tube, Pipe, Ribbon, Disc, Mesh, Powder, Capillary, Crucible, Heat Element, Ingot, Lump, Marker Bands, Single Crystal

Tantalum Alloys

Common alloys include:

- Tantalum–Tungsten (Ta10W, Ta2.5W)

- Tantalum–Niobium (TaNb) Alloys

- Tantalum Base Alloys for High-Temperature & Corrosive Environments

Key Properties of Tantalum

- Extremely High Melting Point: 3,017°C (5,462°F)

- Outstanding Corrosion Resistance (stable Ta?O? oxide layer)

- Excellent Ductility and Formability

- Superior Chemical Inertness even to strong acids

- Good Thermal and Electrical Conductivity

- High Density & Stability at Elevated Temperatures

- Biocompatible and Non-Toxic

- High Vacuum Compatibility (low vapor pressure)

Applications of Tantalum

Tantalum is essential in electronics and semiconductors, where its purity and stability support high-performance capacitors, diffusion barriers in microelectronics, and uniform thin films produced from tantalum sputtering targets.

In chemical processing, tantalum’s exceptional corrosion resistance makes it ideal for heat exchangers, reaction vessels, tubing, and pipeline components exposed to strong acids and aggressive media in pharmaceutical and petrochemical systems.

The aerospace and defense industries rely on tantalum and tantalum-tungsten alloys for high-temperature structural parts and propulsion components that must withstand extreme thermal stress.

In the medical field, tantalum’s biocompatibility supports its use in implants, catheter marker bands, and corrosion-resistant surgical instruments.

Tantalum also serves in high-temperature furnace systems, including crystal-growth crucibles, heating elements, evaporation boats, and radiation-shielding parts for high-vacuum and high-heat environments.

List of Our Tantalum Products

Below is a structured, clean listing of the product families and available size ranges.

|

.002″ x 6″ x 12″ |

.040″ x 12″ x 24″ |

.500″ x 12″ x 24″. |

|

.004″ x 12″ x 24″ |

.050″ x 12″ x 24″ |

.625″ x 12″ x 24″ |

|

.005″ x 12″ x 24″ |

.060″ x 12″ x 24″ |

.750″ x 12″ x 24″ |

|

.010″ x 12″ x 24″ |

.080″ x 12″ x 24″ |

1.00″ x 12″ x 24″ |

|

.015″ x 12″ x 24″ |

.125″ x 12″ x 24″ |

1.50″ x 12″ x 24″ |

|

.020″ x 12″ x 24″ |

.188″ x 12″ x 24″ |

2.00″ x 12″ x 24″ |

|

.025″ x 12″ x 24″ |

.250″ x 12″ x 24″ |

2.50″ x 12″ x 24″ |

|

.030″ x 12″ x 24″ |

.375″ x 12″ x 24″ |

3.00″ x 12″ x 24″ |

|

.125″ dia x 72″ |

.750″ dia x 72″ |

2.25″ dia x 72″ |

|

.188″ dia x 72″ |

.875″ dia x 72″ |

2.50″ dia x 72″ |

|

.250″ dia x 72″ |

1.00″ dia x 72″ |

3.00″ dia x 72″ |

|

.375″ dia x 72″ |

1.25″ dia x 72″ |

3.50″ dia x 72″ |

|

.500″ dia x 72″ |

1.50″ dia x 72″ |

4.00″ dia x 72″ |

|

.625″ dia x 72″ |

2.00″ dia x 72″ |

|

|

Tantalum Ribbon Slit To Size: (Thickness) |

||

|

.002″ |

.005″ |

.008″ |

|

.003″ |

.006″ |

.010″ |

|

.004″ |

.007″ |

.015″ |

|

.125″ od x .015″ wall x 72″ |

.375″ od x .015″ wall x 72″ |

.750″ od x .020″ wall x 72″ |

|

.188″ od x .015″ wall x 72″ |

.375″ od x .020″ wall x 72 |

1.00″ od x .020″ wall x 72″ |

|

.188″ od x .020″ wall x 72″ |

.500″ od x .015″ wall x 72″ |

1.50″ od x .030″ wall x 72″ |

|

.250″ od x .015″ wall x 72″ |

.500″ od x .020″ wall x 72″ |

2.00″ od x .030″ wall x 72″ |

|

.250″ od x .020″ wall x 72″″ |

.625″ od x .020″ wall x 72″ |

2.00″ od x .065″ wall x 72″ |

|

.003" x 50 ft coil |

.030" x 50 ft coil |

.050" x 50 ft coil |

|

.005" x 50 ft coil |

.031" x 50 ft coil |

.059" x 50 ft coil |

|

.010" x 50 ft coil |

.035" x 50 ft coil |

.060" x 50 ft coil |

|

.015" x 50 ft coil |

.039" x 50 ft coil |

.0625" x 50 ft coil |

|

.020" x 50 ft coil |

.040" x 50 ft coil |

|

|

.025" x 50 ft coil |

.047" x 50 ft coil |

|

|

Tantalum Foil / Tantalum Strip (Thickness) |

||

|

0.008 mm |

0.025 mm |

0.03mm |

|

0.050 mm |

0.07 mm |

|

|

Tantalum Crucible (Capacity) |

||

|

1000 ml |

100 ml |

10 ml |

|

15 ml |

20 ml |

25 ml |

|

35 ml |

45 ml |

55 ml |

|

5 ml |

75 ml |

|

|

Metallurgical Grade Tantalum Powder (Particle size) |

||

|

-60 mesh |

-200 mesh |

-325 mesh |

|

1.2mm x 1000mm x 2000mm in coil |

|

|

|

10mm-2000mm |

|

|

|

Tantalum Disc (Thickness) |

||

|

.001″ to .004″ |

.005″ to .020″ |

.021″ to .032″ |

|

.034″ to .120″ |

.125″ to .250″ |

|

|

1.00" Dia. x 0.125" Thick |

1.00" Dia. x 0.250" Thick |

2.00" Dia. x 0.125" Thick |

|

2.00" Dia. x 0.250" Thick |

3.00" Dia. x 0.125" Thick |

3.00" Dia. x 0.250" Thick |

|

4.00" Dia. x 0.125" Thick |

4.00" Dia. x 0.250" Thick |

6.00" Dia. x 0.250" Thick |

|

8.00" Dia. x 0.125" Thick |

8.00" Dia. x 0.250" Thick |

|

|

70-195 mm Dia. |

|

|

|

OD: 0.31-35.00 mm |

WT: 0.08-1.00 mm |

|

|

4V-40V |

20V-60V |

above 60V |

|

10mm |

9mm |

|

|

0.2mm |

0.3mm |

|

|

Diameter: 0.2 ~ 8mm |

Wall Thickness: 0.015 ~ 0.5mm |

|

|

50nm |

10nm |

|

* Specific lengths and sizes available upon request.

FAQs

1. Do you offer custom sizes or shapes?

Yes. All tantalum sheets, plates, rods, wires, tubes, and crucibles can be machined or fabricated to custom dimensions upon request.

2. What industries commonly use tantalum?

Electronics, semiconductors, aerospace, medical devices, chemical processing, vacuum furnaces, and research institutions.

3. Is tantalum safe for medical use?

Yes. Tantalum is biocompatible, non-toxic, and oxidation-stable, making it ideal for implants and surgical devices.

4. Why is tantalum preferred for corrosive chemical environments?

Tantalum forms a self-healing oxide layer that resists nearly all acids—even at high temperatures.

5. Can tantalum be welded or fabricated?

Yes. Tantalum has excellent ductility and weldability, especially in inert atmospheres.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (required)

-

Attachment (Optional)

No file chosen

-

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

- Notes (required)

-

Attachment (Optional)

No file chosen

-