Descriptions of Tungsten

Tungsten also referred to as Wolfram, is a chemical element with the chemical symbol W and atomic number 74. After Carbon, Tungsten has the highest melting point of all elements. Tungsten is among the heaviest metals found on Earth. It has excellent high-temperature mechanical properties, with the lowest expansion coefficient and highest conductivity of all metals.

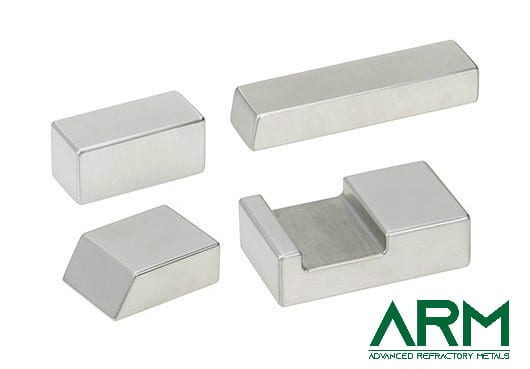

Advanced Refractory Metals is a leading supplier of Tungsten products. We offer competitive pricing and great lead times on all our materials, and we're capable of supplying custom materials per any specs/drawings you provide us with.

List of Our Tungsten Products

We offer a range of tungsten and tungsten-based alloys, known for their extreme density, high melting point, and excellent performance in tough environments.

Products Available

-

Pure Tungsten Rods, Plates, Sheets

-

Tungsten Heavy Alloy (W-Ni-Fe, W-Ni-Cu) Bars & Blocks

-

Tungsten Electrodes (for welding and plasma)

-

Tungsten Radiation Shielding Components

-

Custom-Machined Tungsten Parts

| Tungsten Sheet & Tungsten Plate | ||

| .002″ x 12″ x 36″ | .050″ x 12″ x 36″ | .750″ x 12″ x 36″ |

| .004″ x 12″ x 36″ | .060″ x 12″ x 36″ | 1.00″ x 12″ x 36″ |

| .005″ x 12″ x 36″ | .080″ x 12″ x 36″ | 1.50″ x 12″ x 36″ |

| .010″ x 12″ x 36″ | .125″ x 12″ x 36″ | 2.00″ x 12″ x 36″ |

| .015″ x 12″ x 36″ | .188″ x 12″ x 36″ | 2.50″ x 12″ x 12″ |

| .020″ x 12″ x 36″ | .250″ x 12″ x 36″ | 3.00″ x 12″ x 12″ |

| .025″ x 12″ x 36″ | .375″ x 12″ x 36″ | 3.50″ x 12″ x 12″ |

| .030″ x 12″ x 36″ | .500″ x 12″ x 36″ | 4.00″ x 12″ x 12″ |

| .040″ x 12″ x 36″ | .625″ x 12″ x 36″ | |

| Tungsten Rod & Tungsten Bar | ||

| .125″ dia x 72″ | .750″ dia x 72″ | 2.00″ dia x 72″ |

| .188″ dia x 72″ | .875″ dia x 72″ | 2.25″ dia x 36″ |

| .250″ dia x 72″ | 1.00″ dia x 72″ | 2.50″ dia x 36″ |

| .375″ dia x 72″ | 1.25″ dia x 72″ | 3.00″ dia x 36″ |

| .500″ dia x 72″ | 1.50″ dia x 72″ | 3.50″ dia x 36″ |

| .625″ dia x 72″ | 1.75″ dia x 72″ | 4.00″ dia x 36″ |

| Tungsten Wire | ||

| .00059” dia x 50 ft | .0008” dia x 50 ft | .001” dia x 50 ft |

| .0015” dia x 50 ft | .002″ dia x 50 ft | .025″ dia x 50 ft |

| .003″ dia x 50 ft | .005″ dia x 50 ft | .008″ dia x 50 ft |

| .010″ dia x 50 ft | .015″ dia x 50 ft | .020″ dia x 50 ft |

| .030″ dia x 50 ft | .035″ dia x 50 ft | .040″ dia x 50 ft |

| .045″ dia x 50 ft | .050″ dia x 50 ft | .060″ dia x 50 ft |

| .062″ dia x 50 ft | .080″ dia x 50 ft | .090″ dia x 50 ft |

| .125″ dia x 50 ft | ||

| Ribbon Thicknesses: | ||

| .002″ | .006″ | .012″ |

| .003″ | .007″ | .015″ |

| .004″ | .008″ | .020″ |

| .005″ | .010″ | .025″ |

| Tungsten Powder (Particle Size) | ||

| 0.4-0.5 μm | 0.5-0.7 μm | 0.7-0.9 μm |

| 0.9-1.1 μm | 1.1-1.5 μm | 1.5-1.8 μm |

| 1.8-2.2 μm | 2.2-2.7 μm | 2.7-3.2 μm |

| 3.2-3.7 μm | 3.7-4.3 μm | 4.3-4.8 μm |

| 4.8-5.3 μm | 5.3-6.0 μm | 6.0-6.5 μm |

| 6.5-7.0 μm | 7.0-9.0 μm | 9.0-11.0 μm |

| 11.0-13.0 μm | 13.0-17.0 μm | 17.0-25.0 μm |

| 25.0-35.0 μm | 35.0-45.0 μm | 45.0-55.0 μm |

| Tungsten Boat | ||

| 2.5mm-100mm height | 15mm-900mm width | 15mm-900mm length |

| 0.25mm-8mm thickness | ||

| Tungsten Crucible (Diameter) | ||

| 30 ~ 50 mm | 50 ~ 100 mm | 100 ~ 150 mm |

| 150 ~ 200 mm | 200 ~ 300 mm | 300 ~ 400 mm |

| 400 ~ 450 mm | 450 ~ 500 mm | |

| Tungsten Wire Rope | ||

| 2.5 X 6700 X 2820 mm | 2.0 X 4010 X 1800 mm | 1.8 X 3700 X 1570 mm |

| Tungsten Nickel Iron Alloy (W-Ni-Fe Alloy) | ||

| Tungsten Nickel-Copper Alloy (W-Ni-Cu Alloy) | ||

| Tungsten Bucking Bar | ||

| Tungsten Alloy Counterweight Parts | ||

| Tungsten Alloy Crankshaft Weight | ||

| Tungsten Penetrator | ||

| Tungsten Rhenium Alloy Wire | ||

| Tungsten Rhenium Alloy Plate | ||

| Tungsten Rhenium Alloy Rod | ||

| Tungsten Rhenium Alloy Sheet | ||

| Tungsten Rhenium Alloy Thermocouple | ||

* Specific lengths and sizes available upon request.

Applications of Tungsten

Tungsten has many excellent properties such as high melting point and low vapor pressure, so it is widely used in industrial fields.

* Useful for glass-to-metal seals since the thermal expansion is about the same as borosilicate glass

* Tungsten and its alloys are used extensively for filaments for electric lamps, electron, and television tubes, and for metal evaporation work

* Electrical contact points for car distributors

* X-ray targets

* Windings and heating elements for electrical furnaces

* Missile and high-temperature applications

* High-speed tool steels and many other alloys contain tungsten

FAQs

Q: What's the difference between pure tungsten and tungsten heavy alloy?

A: Pure tungsten is very dense and heat-resistant, but brittle. Alloys add nickel, iron, or copper to improve toughness and workability.

Q: Is tungsten magnetic?

A: Pure tungsten is not magnetic. Alloys may be slightly magnetic depending on the binder metals used.

Q: Do you offer custom parts?

A: Yes, we offer custom machining for both pure tungsten and alloys. Just send us a drawing or specs.

Q: How does tungsten compare to lead for shielding?

A: Tungsten is denser and safer—no toxicity issues like lead. Ideal for compact, high-performance shielding.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (required)

-

Attachment (Optional)

No file chosen

-

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

- Notes (required)

-

Attachment (Optional)

No file chosen

-