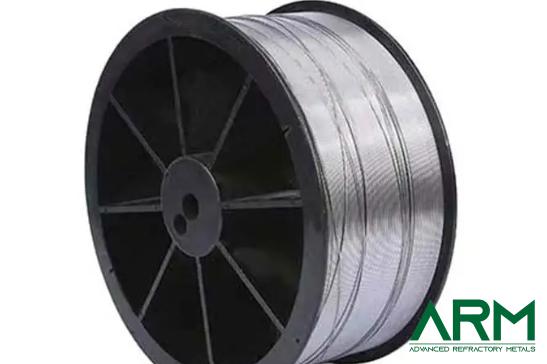

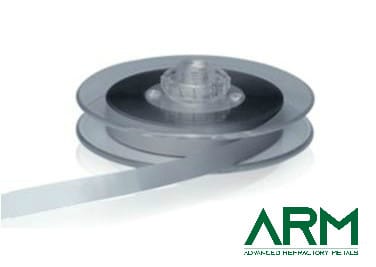

TA0006 Tantalum Wire

Tantalum Wire is corrosion resistant and has good thermal conductivity. Tantalum Wire can be used in the manufacture of heating elements, vacuum tubes, and other high-temperature parts.

Descriptions of Tantalum Wire

Tantalum Wire is corrosion resistant and has good thermal conductivity. Tantalum Wire can be used in the manufacture of heating elements, vacuum tubes, and other high-temperature parts. Tantalum Wire can take hydrogen, oxygen, and nitrogen away from the atmosphere and is the ideal product for vacuum applications in the lighting industry.

Specifications of Tantalum Wire

| Size | Diameter 0.1-4 mm |

|---|---|

| Material | R05200 R05400 |

| Standard | ASTM B365; ASTM F560(Medical Grade) |

| Purity | >=99.9% or 99.95% |

Mechanical properties for tantalum metal wire:

| Product condition | Tensile strength (MPa) | Elongation, % |

| Annealed | 300~600 | 10~30 |

| Half annealed | >600~1000 | <5 |

| Unannealed | >1000 | <5 |

Materials Chemical composition for tantalum and tantalum alloy wire:

Grades: R05200, R05400, UNS Grade R05252 (Ta2.5W), UNS Grade R05255 (Ta10W), UNS Grade R05240 (Ta40Nb)

| Element | R05200 | R05400 | R05255 | R05252 | R05240 |

| C | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| O | 0.015 | 0.03 | 0.015 | 0.015 | 0.02 |

| N | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| H | 0.0015 | 0.0015 | 0.0015 | 0.0015 | 0.0015 |

| Fe | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Mo | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Nb | 0.1 | 0.1 | 0.1 | 0.5 | 35.0–42.0 |

| Ni | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Si | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |

| Ti | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| W | 0.05 | 0.05 | 9.0–11.0 | 2.0–3.5 | 0.05 |

Applications of Tantalum Wire

-

Electronics and Capacitors

Tantalum wire is widely used as an anode lead in tantalum electrolytic capacitors due to its excellent conductivity, high melting point, and ability to form a stable oxide layer. These capacitors are compact, reliable, and essential in smartphones, computers, medical electronics, and automotive systems. -

Medical Devices

Thanks to its biocompatibility and corrosion resistance, tantalum wire is used in medical implants, surgical clips, and dental hardware. It’s particularly valued in applications where long-term implantation and tissue compatibility are critical. -

Aerospace and Defense

In aerospace systems, tantalum wire is used in high-temperature components, thermocouples, and alloying applications. Its strength and stability under extreme conditions make it ideal for jet engines, missiles, and satellite parts. -

Vacuum Furnace Components

Tantalum’s high melting point (~3017 °C) and chemical inertness make tantalum wire suitable for heating elements and structural components in high-temperature vacuum furnaces. -

Thin-Film Deposition

Tantalum wire is used as a filament in vacuum evaporation and sputtering systems to deposit thin films of tantalum or other metals onto substrates in semiconductor manufacturing and optical coatings. -

Chemical Processing

Tantalum’s resistance to corrosion by acids makes it useful in wiring for chemical reactors, heat exchangers, and pipelines in harsh environments involving strong acids like hydrochloric or sulfuric acid. -

Nuclear Industry

Tantalum wire is utilized in nuclear reactors for its low neutron absorption cross-section and high-temperature stability, particularly in control rods and radiation shielding applications.

Packaging of Tantalum Wire

Our Tantalum Wire is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage on items which might be caused during storage or transportation.

Related reading:

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-