NC1240 INCOLOY 825

Alloy 825 is a Nickel-iron-chromium alloy with additions of molybdenum, copper and titanium. The alloys chemical composition provides exceptional resistance to many corrosive environments.

Descriptions of INCOLOY 825

Alloy 825 is a Nickel-iron-chromium alloy with additions of molybdenum, copper and titanium. The alloys chemical composition provides exceptional resistance to many corrosive environments.

The Nickel content is sufficient for resistance to Chloride-ion stress corrosion cracking. The nickel, combined with molybdenum and copper, also gives outstanding resistance to reducing environments such as those containing sulfuric and phosphoric acid. The molybdenum also aids resistance to pitting and crevice corrosion. The alloy Chromium content confers resistance to a variety of oxidizing substances such as nitric acid, nitrates and oxidizing salts. The titanium addition, with appropriate heat treatment, will stabilize the alloy against sensitization to intergranular corrosion.

INCOLOY 825 Available Forms

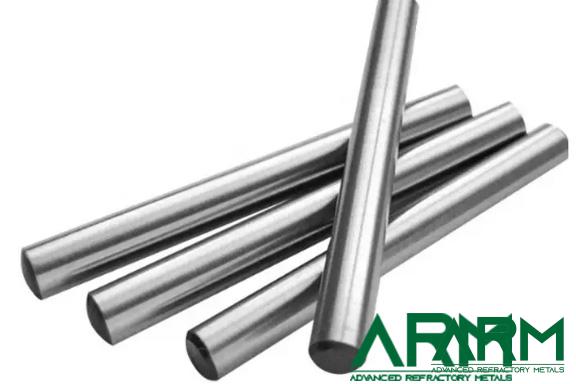

Bar

Wire

Sheet

Plate

Flange

Rod

Specifications of INCOLOY 825

Metal Type: UNS N08825

Standard: ASTM B423, ASTM B829, ASTM B705, ASTM B775, ASTM B163, ASTM B704, ASTM B751, DIN 17751, ISO 6207, VdTüV 432

Chemical Composition, %

| Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al | |

| Min | 38 | 22 | 19.5 | 2.5 | 1.5 | 0.6 | |||||

| Max | 46 | 23.5 | 3.5 | 3.0 | 1.2 | 0.05 | 1.0 | 0.03 | 0.5 | 0.2 |

Applications of INCOLOY 825

- Sulfuric acid pickling plant equipment, including heating coils, tanks, crates, baskets and chains

- Fuel element dissolvers

- Offshore product piping system components and tubes sour gas service

- Seawater-cooled heat exchangers

- Paper industry – pipe digesters

- Pipelines for wet sulfur dioxide gas

- Phosphoric acid production equipment, including heat exchangers, evaporators and scrubbers

- LPG (liquid petroleum gas) processing equipment, including air-cooled heat exchangers

Packaging of INCOLOY 825

Our INCOLOY 825 is carefully handled to minimize damage during storage and transportation and to preserve the quality of the product in its original condition.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-