Properties and Applications of Tungsten Copper Alloy

Properties and Applications of Tungsten Copper Alloy

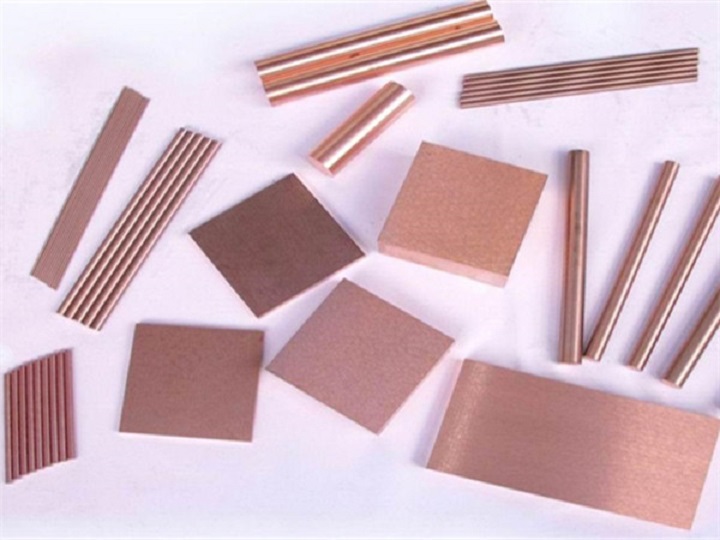

Tungsten copper alloys are widely used in military, national defense, aerospace, aviation, navigation, electronic devices, medical equipment, and other fields due to their excellent physical and chemical properties. However, due to the large difference in physical and chemical properties between tungsten and copper, they cannot be produced by melting and casting, and powder metallurgy technology is generally used for production. In this article, let's take a closer look at the properties and applications of tungsten copper alloy.

Properties and Applications of Tungsten Copper Alloy

Properties of Tungsten Copper Alloy

Since tungsten and copper are two incompatible metals, copper-tungsten alloy combines the advantages of tungsten and copper, which is mainly manifested in its small volume expansion coefficient, good wear resistance, and corrosion resistance, excellent electrical and thermal conductivity, and good high-temperature resistance.

Tungsten Copper Alloy Production Process

The process flow of preparing tungsten copper alloy by powder metallurgy: pulverizing→mixing of ingredients→press molding→sintering infiltration→cold processing.

Applications of Tungsten Copper Alloy

1. Tungsten Copper Electrode

Tungsten Copper Electrode is suitable for use in welding electrodes due to its good high-temperature resistance, arc ablation resistance, high specific gravity, and easy machining.

2. Tungsten Copper Alloy Rod

It is a composite material refined through the process of static pressing, high-temperature sintering, and copper infiltration using the excellent metal properties of high-purity tungsten powder and the plasticity and high conductivity of high-purity copper powder. It has the characteristics of good arc-breaking performance, no softening at high temperatures, high strength, and high hardness.

3. Tungsten Copper Electronic Packaging Sheet

It has both the low expansion characteristics of tungsten and the high thermal conductivity of copper. It is worth noting that the performance of the electronic packaging sheet can be changed by adjusting the ratio of the constituent materials.

4. Tungsten Copper Tube

5. Tungsten Copper Alloy Wire

Precautions for its use:6. Military High-Temperature Materials

Copper-tungsten alloys are used as nozzles, gas rudders, air rudders, and nose cones of missiles and rocket engines in aerospace. The main requirements are high-temperature resistance (3000K~5000K) and high-temperature resistance to airflow erosion. The sweat cooling effect formed by the volatilization of copper at high temperatures (copper melting point 1083℃) is mainly used to reduce the surface temperature of tungsten copper and ensure its use under extreme high-temperature conditions.Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the properties and applications of tungsten copper alloy. If you want to learn more about tungsten copper alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information. Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as niobium, molybdenum, tantalum, rhenium, tungsten, titanium, and zirconium at a very competitive price.{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}