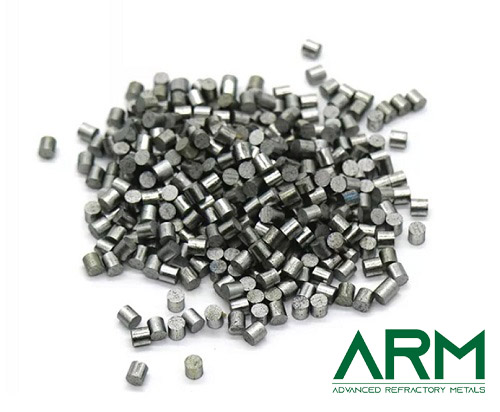

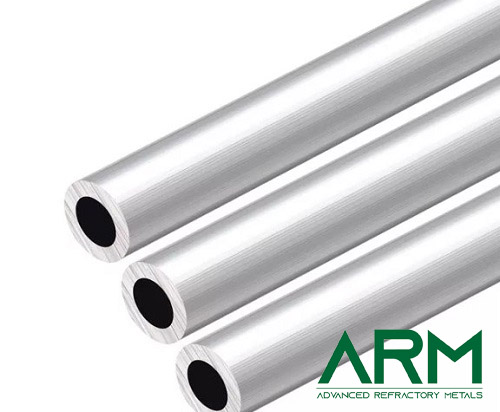

MU0077 Molybdenum Rod & Molybdenum Bar

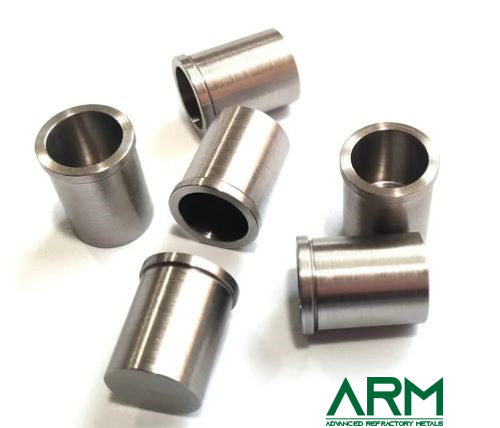

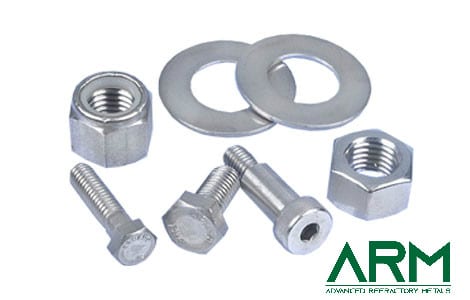

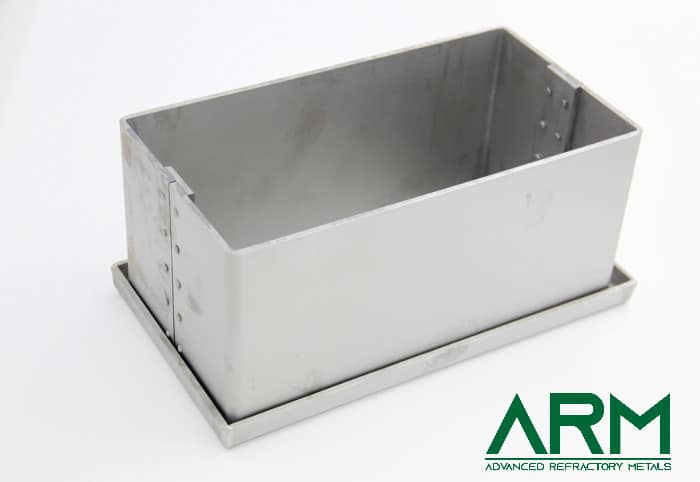

Molybdenum rod & bar can be manufactured into wire, electrode, steel-making additives, electric vacuum parts, gas pipes, lead-wire, pole, sidebars, daily-use glass, optical glass, insulation material, and glass fiber. Small crucibles and tubes are machined from Moly rods.

Descriptions of Molybdenum Rod & Bar

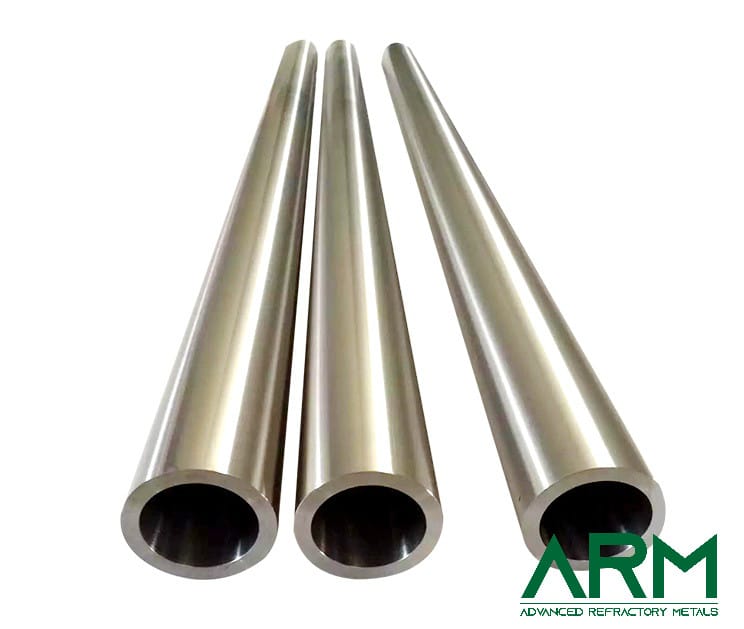

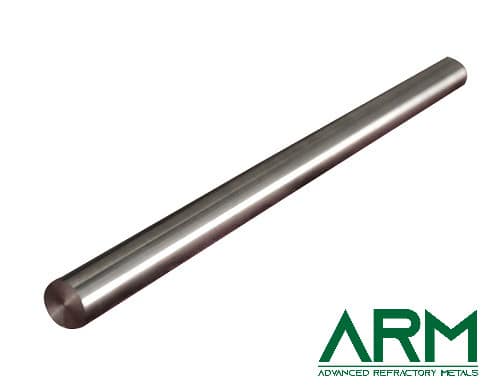

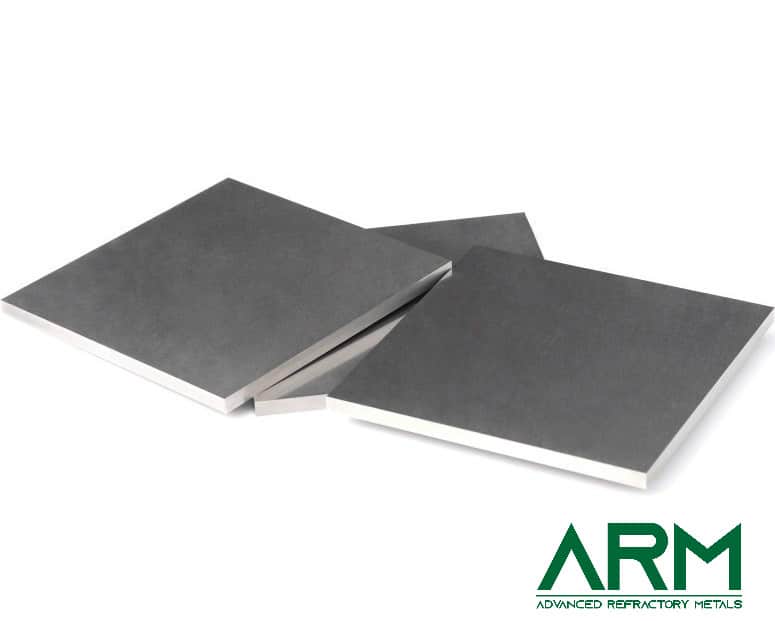

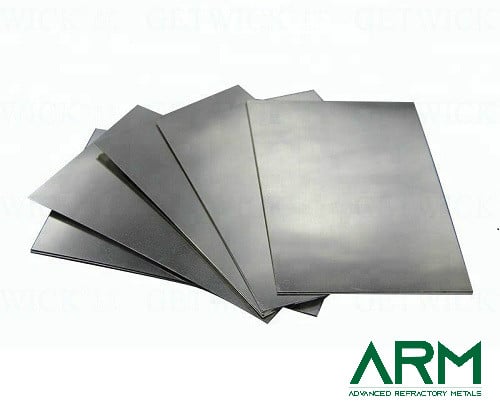

Molybdenum rods and bars offer high strength, thermal stability, and corrosion resistance. Ideal for furnace parts, electrodes, aerospace components, and machining, they perform reliably in extreme temperatures and demanding industrial environments.

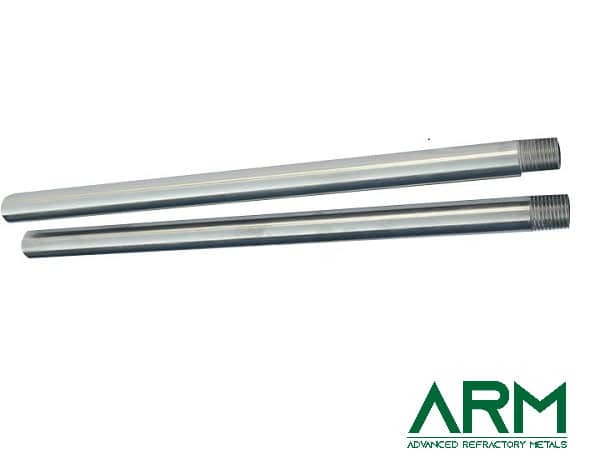

Available in various diameters and lengths, molybdenum rods and bars are typically produced through powder metallurgy or vacuum arc melting processes, ensuring high density and purity. The material's unique combination of properties - including low thermal expansion, good electrical conductivity, and resistance to molten metals - makes it indispensable for critical applications across multiple industries.

Surface finishes range from forged black to ground/polished, with optional machining into custom shapes and sizes.

Specifications of Molybdenum Rod & Bar

We carry a full line of standard rods and bars. Apart from this, our moly bars and moly rods are available in various dimensions upon your request.

| Standard | ASTM B387/B387M |

| Material | Mo |

| Dimensions | >4.0 mm Dia. x L, customized |

| Purity | ≥99.9% |

| Shape | Rod/Bar |

* Surface Finish of Molybdenum Rod & Molybdenum Bar

We offer three types of surface finish as followed:

- Cleaned: the surface is chemically cleaned to remove all lubricants and oxides.

- Black: the surface is either as swaged or as drawn and retains a coating of processing lubricants and oxides.

- Ground: the surface is center-less ground to remove all coating and to achieve precise diameter control.

Chemical Composition, %

|

Grade |

C |

O |

N |

Fe |

Ni |

Si |

Mo |

|

Mo 360 |

≤0.03 |

≤0.0015 |

≤0.002 |

≤0.01 |

≤0.002 |

≤0.01 |

Bal. |

|

Mo 361 |

≤0.01 |

≤0.007 |

≤0.002 |

≤0.01 |

≤0.005 |

≤0.01 |

Bal. |

Applications of Molybdenum Rod & Bar

High-Temperature Furnaces - Used as heating components and supports in extremely high-temperature service.

Aerospace - Needed for rocket nozzle and turbine hardware due to heat resistance.

Glass Production - Used as durable electrodes and stirrers in molten glass processing.

Semiconductors - Provides high-purity sputtering targets for thin-film deposition.

Medical Devices - Used in X-ray tubes and radiation shielding for reliable operation.

Nuclear Applications - Ideal for reactor hardware due to low neutron absorption.

Types and Uses of Molybdenum Rod

Molybdenum rods come in various forms, including:

-

Pure molybdenum rods – for general high-temperature use.

-

TZM alloy rods (Titanium-Zirconium-Molybdenum) – offer higher strength and creep resistance.

-

Mo-La rods (Molybdenum-Lanthanum) – enhanced ductility and performance in extreme environments.

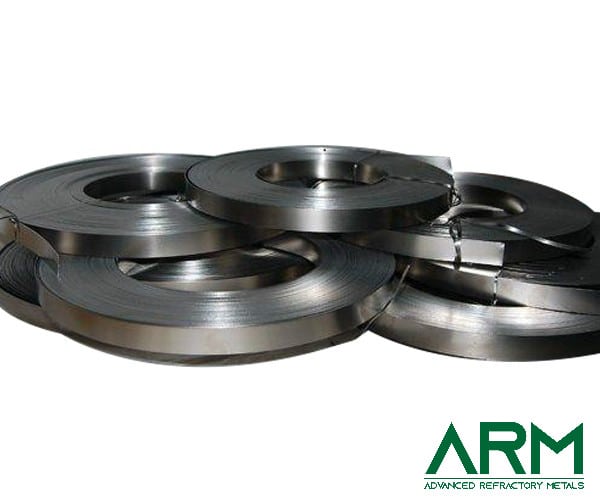

Packaging of Molybdenum Rod & Bar

Our moly rods and moly bars are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Related reading:

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (required)

-

Attachment (Optional)

No file chosen

-