Tungsten Alloy for Bullets

Tungsten Alloy for Bullets

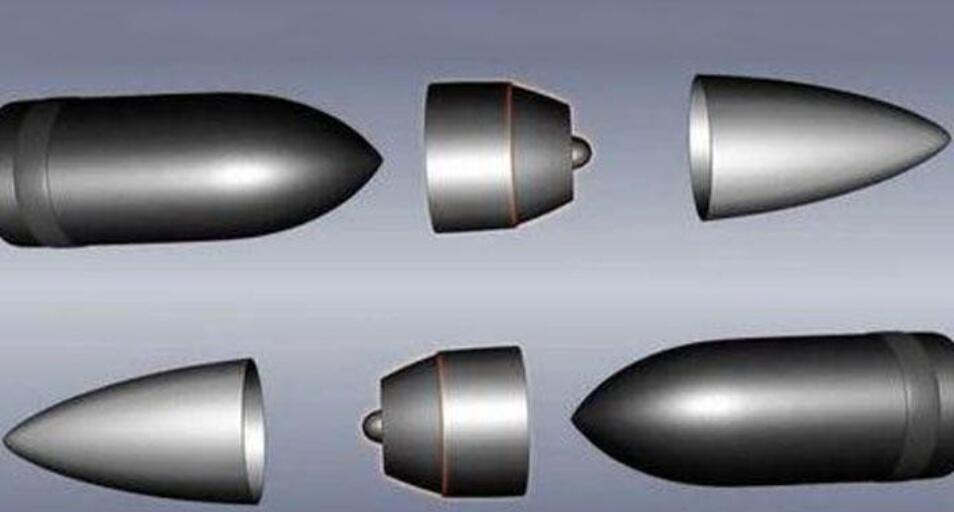

In order to avoid environmental pollution caused by lead bullets, people began to manufacture tungsten alloy bullets. This kind of bullet has less environmental pollution, but in terms of accuracy, lethality, and penetration, tungsten alloy bullets are much better than lead bullets. In this article, let's take a deeper look at the tungsten alloy for bullets.

Tungsten Alloy for Bullets

As early as 1999, there were reports that the United States would start using new tungsten core bullets. This new copper-shell tungsten bullet uses a tungsten-polymer composite material to replace the old lead-antimony alloy core. Even at that time, the US military had planned to produce 1 million tungsten alloy bullets to replace all the military's bullet cores with new tungsten core bullets. However, due to cost issues, the plan did not take place.

Tungsten Alloy Shotgun Bullet

Tungsten alloy shotgun bullets are non-toxic, environmentally friendly, and pollution-free new shotgun bullets were developed to replace lead bullets. Before tungsten alloy bullets were developed, shotguns used lead bullets.

At that time, in terms of density and hardness, lead was considered a more suitable bullet material. However, shotguns are used for hunting. If the shotgun uses toxic heavy metal lead bullets, no matter how healthy the prey is, people can't help but worry about the safety of eating.

The tungsten alloy shotgun bullets, in addition to being environmentally friendly, have higher density and hardness than traditional lead bullets and are more suitable for hunting edible animals with shotguns. Earlier, an American metal company developed a shotgun bullet composed of 50% W-35% Ni-15% Fe as a substitute for lead bullets. The bullet weighs 12g.

Tungsten Alloy Armour Piercing Projectile

Tungsten alloy armor-piercing projectile refers to a kinetic energy projectile that uses tungsten alloy as the core material of the armor-piercing projectile. It can be a large-caliber kinetic energy armor-piercing projectile, a machine gun shelling armor-piercing projectile, a rod-type kinetic energy armor-piercing projectile, and so on.

The reason why tungsten alloy can be used in the military field to make armor-piercing projectile core materials is that tungsten alloy has a high melting point, high density, high strength, low thermal expansion coefficient, corrosion resistance, and good mechanical processing, and other comprehensive properties.

In fact, as early as the 1950s, the development of tungsten alloy armor-piercing ammunition has begun. In the 1970s, the United Kingdom, the United States, West Germany, and other countries used liquid-phase sintered high-density tungsten alloys (W-Ni-Fe and W-Ni-Cu) for large-caliber shelling and armor-piercing bullet cores and grenade warheads. This greatly improves the toughness of the bullet core and increases the armor-piercing power.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the tungsten alloy for bullets. If you want to learn more about tungsten alloy or other types of refractory materials, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as tungsten, tungsten alloy, niobium, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}