4 Types of Rhenium Alloys You Mightn't Know

4 Types of Rhenium Alloys You Mightn't Know

Rhenium is a silvery-white rare high melting point metal that is hard, wear-resistant, and corrosion-resistant. Rhenium is stable in air, insoluble in hydrochloric acid, and does not interact with hydrogen and nitrogen. Because of the high price of rhenium, the application of rhenium-containing alloys is mostly used. In this article, we will introduce 4 types of rhenium alloys that are widely used in aerospace, electronics, petrochemical, and other fields.

Rhenium Alloys

1. Platinum-rhenium Alloy

Platinum-rhenium alloy is a binary alloy based on platinum and added with rhenium. There are two kinds of platinum-rhenium alloys: PtRe8 and PtRel4. PtRe8 is a high-temperature thermocouple material, which can be used with rhodium for an instantaneous temperature of 1800 ° C and platinum at 1600 ° C. And PtRel4 alloy can be used as electrical contact material.

2. Platinum-tungsten-rhenium Alloy

Platinum-tungsten-rhenium alloy is a platinum-based ternary alloy containing tungsten and rhenium. A small amount of rhenium can improve the resistivity and tensile strength, and reduce the temperature coefficient of resistance. Platinum-tungsten-rhenium alloy can be used as resistance strain material, which can be used at temperatures above 800.

3. Tungsten-rhenium Alloy

The tungsten-rhenium alloy is a solid solution-strengthened alloy based on tungsten and added with rhenium. The rhenium content (mass fraction,%) in tungsten-rhenium alloys is usually 3, 5, 10, 25, and 26. Tungsten-rhenium alloy is divided into low-content W-Re alloy (Re≤5%) and high-content W-Re alloy (Re≥15%).

The Properties of Tungsten-rhenium Alloys

Tungsten-rhenium alloy has a series of excellent properties, such as high melting point, high strength, high hardness, high plasticity, high recrystallization temperature, high resistivity, high thermoelectric potential value, low vapor pressure, and so on.

The Applications of Tungsten-rhenium Alloys

Tungsten and rhenium are refractory metals, and they are widely used in high-temperature fields. But they also have shortcomings. For example, pure tungsten is brittle and the recrystallization temperature is very low; pure rhenium has poor processing performance and is expensive. Therefore, their application range is greatly restricted.

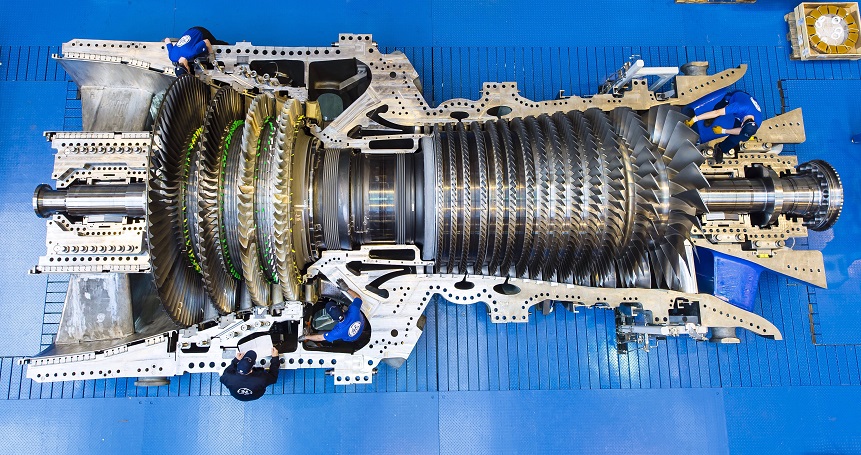

However, the tungsten-rhenium alloy made of tungsten and rhenium overcomes the shortcomings of pure tungsten and pure rhenium and has many excellent properties. Therefore, it has been widely used in electronic technology, thermal control, modern nuclear technology and space navigation technology, temperature measurement, instrumentation, electrical appliances, and other cutting-edge science and technology departments.

Applications of Rhenium Alloys

Especially thermocouple made of tungsten-rhenium alloy wire has high thermoelectric potential and sensitivity and has a wide temperature measurement range, fast reaction speed, good corrosion resistance, and is good thermal sensing material in the field of temperature measurement. It is the general trend to replace platinum-rhodium thermocouples with tungsten-rhenium thermocouples.

4. Molybdenum-rhenium Alloy

The molybdenum rhenium alloy is based on molybdenum, with 2% to 5% rhenium added. The addition of rhenium to molybdenum can improve the plasticity and strength of molybdenum. The molybdenum-rhenium alloy can be prepared by powder metallurgy.

The Applications of Molybdenum-rhenium Alloys

Molybdenum-rhenium alloys can be used as a high-speed rotating X-ray tube target, microwave communication long-life grid, space reactor core heating tube, high-temperature furnace heating element, high-temperature thermocouple, etc.

The room temperature tensile strength, ductility, and resistivity of the molybdenum-rhenium alloy increase with the increase of rhenium content. Generally, Mo-5% Re and Mo-41% Re are used as thermocouple wires and structural materials in aerospace. Mo-50% Re is used as a high-temperature structural material.

Conclusion

Thank you for reading our article, and we hope it can help you have a better understanding of the types of rhenium alloys. If you want to know more about rhenium and rhenium alloys, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, ARM is a leading manufacturer & supplier of refractory metals in the world. We offer customers high-quality refractory metal products such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very affordable price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}