List of Refractory Metals in Alloying

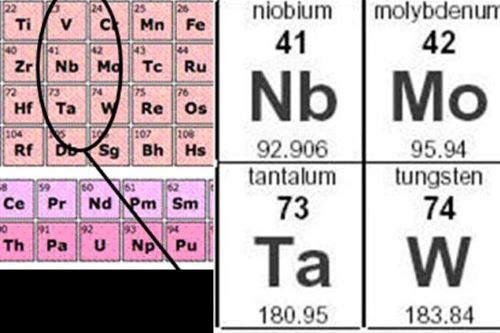

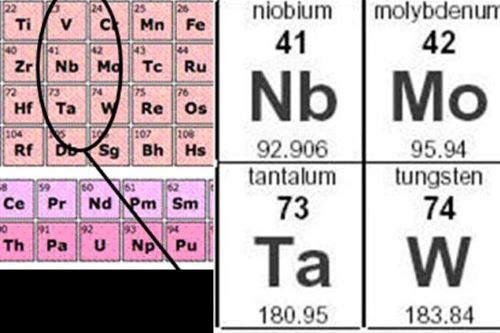

Refractory metals like molybdenum (Mo), niobium (Nb), and rhenium (Re) are integral to high-performance alloys due to their remarkable properties, such as high melting points, strength, and resistance to corrosion. We will discuss the principles behind alloying with these refractory metals, how they modify the properties of alloys, the benefits they offer, and the common applications in which these alloys are used.

Molybdenum Addition in Alloys

Principle of Molybdenum Alloying

Molybdenum is primarily used to enhance the properties of steel and other high-performance alloys. Molybdenum forms a solid solution that increases the steel's hardness, toughness, and resistance to wear and corrosion, especially at high temperatures. Molybdenum plays a critical role in preventing grain boundary strengthening and improving the steel's resistance to corrosion in acidic environments.

Common Alloying Partners

Molybdenum is frequently alloyed with several other elements to further enhance the properties of the material:

- Chromium (Cr): Molybdenum and chromium combine to form stainless steels and corrosion-resistant alloys. Chromium enhances molybdenum's corrosion resistance.

- Vanadium (V): Often used alongside molybdenum, vanadium further improves the hardness and strength of steel, especially in high-temperature applications.

- Nickel (Ni): Adding nickel to molybdenum alloys increases the alloy's resistance to oxidation and corrosion, making it ideal for high-temperature environments like gas turbines.

Related reading: Top 10 Common Refractory Metals You Can Find Now

Applications

Molybdenum is used in the manufacture of turbine blades and other high-performance components that must withstand high temperatures. The high conductivity and wear resistance of molybdenum make it suitable for electrical contacts in harsh environments. Due to its resistance to corrosion, molybdenum is commonly used in the production of chemical processing equipment, especially in environments that involve acidic or high-temperature conditions.

Niobium Addition in Alloys

Principle of Niobium Alloying

Niobium is a refractory metal often used in alloys to improve their strength, resistance to oxidation, and ability to function in high-temperature conditions. Niobium is known for its ability to form strong, lightweight alloys with excellent thermal stability. Its addition to steel and high-temperature alloys improves their weldability, ductility, and overall toughness.

Common Alloying Partners

Niobium is often alloyed with the following elements to create high-performance materials:

- Titanium (Ti): Niobium and titanium are commonly combined to create lightweight alloys for the aerospace and automotive industries.

- Zirconium (Zr): Niobium is alloyed with zirconium in nuclear reactors to improve the strength and corrosion resistance of the materials used in reactor cores.

- Tin (Sn): Niobium is used with tin in superconducting materials, especially in the production of magnets for medical equipment like MRI machines.

Applications

Niobium alloys are used to manufacture lightweight components in rocket nozzles and engine parts. Niobium-titanium and niobium-tin alloys are critical in the manufacturing of superconducting magnets, such as those used in MRI machines and other medical technologies. Niobium is used in automotive components, especially those requiring high strength and durability at elevated temperatures.

Rhenium Addition in Alloys

Principle of Rhenium Alloying

Rhenium is one of the rarest and most expensive metals used in alloying. It is typically added to superalloys to improve their strength, corrosion resistance, and ability to maintain structural integrity at extremely high temperatures. Rhenium is often used in the aerospace and defense industries for components that must withstand both high temperature and stress.

Common Alloying Partners

Rhenium is often alloyed with the following metals:

- Tungsten (W): Rhenium-tungsten alloys are known for their excellent high-temperature performance, making them ideal for aerospace applications.

- Molybdenum (Mo): When combined with molybdenum, rhenium alloys offer enhanced strength and resistance to wear at high temperatures.

- Cobalt (Co): Rhenium is also alloyed with cobalt in superalloys used in jet engines and gas turbines, where high strength and thermal stability are required.

Applications

The addition of rhenium to superalloys used in gas turbines allows the engines to operate at higher temperatures, improving efficiency and performance. Rhenium is also used in electronics, particularly in the production of electrical contacts that require excellent conductivity and durability at high temperatures.

Summary Table: List of Refractory Metals in Alloying

|

Metal |

Key Properties |

Common Alloying Partners |

Common Applications |

|

Molybdenum (Mo) |

High melting point (2,623°C), corrosion-resistant, hard, good conductivity |

Chromium (Cr); Vanadium (V); Nickel (Ni) |

Electrical contacts; Chemical equipment |

|

Niobium (Nb) |

High melting point (2,477°C), excellent high-temperature stability, corrosion-resistant |

Titanium (Ti); Zirconium (Zr); Tin (Sn) |

Superconducting magnets; Automotive |

|

Rhenium (Re) |

High melting point (3,180°C), excellent high-temperature strength, oxidation-resistant |

Tungsten (W); Molybdenum (Mo); Cobalt (Co) |

Gas turbines; Electronics (high-temperature contacts) |

For more information, please check Advanced Refractory Metals (ARM).

Conclusion

Molybdenum, niobium, and rhenium are indispensable in alloying due to their ability to significantly improve the mechanical properties, high-temperature strength, and resistance to corrosion of materials. Whether it's molybdenum strengthening steel, niobium creating superconducting alloys, or rhenium boosting the performance of turbine engines, these refractory metals play a crucial role in advancing modern industrial technologies.

Reference:

[1] Capriotti, Luca & Quaini, Andrea. (2012). High temperature behaviour of nuclear materials investigated by laser heating and fast pyrometry. 10.13140/RG.2.1.1969.0967.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}