Advantages & Disadvantages of Tungsten Alloy Marine Counterweights

Advantages & Disadvantages of Tungsten Alloy Marine Counterweights

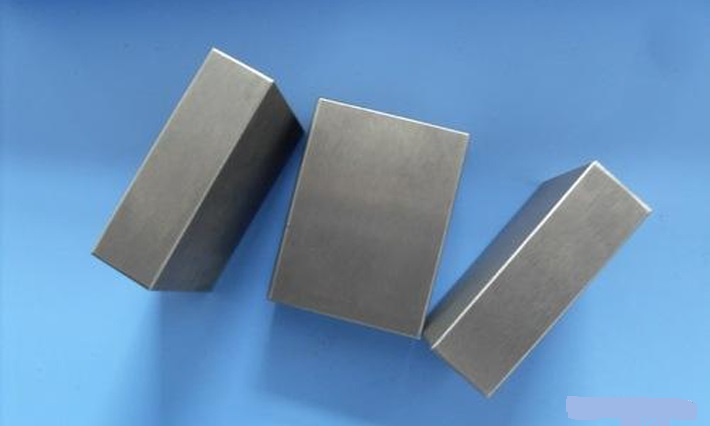

Tungsten alloy marine counterweights are ideal materials for marine counterweights. This is not only because it is more friendly to the water environment, but also because of its high density (18.6g/cm3), easy machining, high tensile strength, and hardness, which can make the ship more stable. In this article, we will compare the advantages & disadvantages of tungsten alloy marine counterweights and other counterweights.

Advantages & Disadvantages of Tungsten Alloy Marine Counterweights

Iron Counterweight

Advantages

1. Relatively environmentally friendly and low energy consumption in the production process.

2. No pollution treatment during use and after use.

3. It can be recycled and reused.

Disadvantages

Easy to rust, poor corrosion resistance, and short service life.

Application of Iron Counterweights

Iron counterweights are suitable for equipment with low production costs and long-term operation in dry environments. It is best not to expose them to oxygen.

Zinc Counterweight

Advantages

1. It has good gloss and can improve the aesthetics of the equipment.

2. It has good corrosion resistance and can extend the usage time.

3. No pollution to the ecological environment during and after use.

Disadvantages

1. High production costs.

2. It consumes a lot of electricity during manufacturing, and the pollution is serious during the production process.

Lead Counterweight

Advantages

1. The price of lead is lower, which can effectively reduce the cost of related equipment.

2. The manufacturing of lead counterweight is simple, which can save the operator's time to a certain extent.

Disadvantages

1. Lead is a heavy metal, which pollutes the environment.

2. The production process of this product is outdated, with high energy consumption and high pollution.

3. This product is difficult to recycle.

Application of Lead Counterweights

Lead counterweights are suitable for lower-priced equipment.

Tungsten Alloy Counterweight

Advantages

1. Tungsten alloy counterweights are more environmentally friendly and have less pollution to the environment.

2. The density is large, the weight distribution is easier to control, and the volume of the prepared counterweight is also small.

3. Good corrosion resistance and long service life.

Disadvantage

The material price is relatively high.

Application of Tungsten Alloy Counterweights

Tungsten alloy counterweights are suitable for use in the shipbuilding industry.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the advantages & disadvantages of tungsten alloy marine counterweights. If you want to learn more about tungsten alloys or other types of refractory metals and alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as molybdenum, tantalum, rhenium, tungsten, tungsten alloys, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}