Why Tungsten Alloys Are Ideal for Aviation Balance Weights

In modern aerospace engineering, balance and stability are not optional—they are mission-critical. Aircraft must maintain a precise center of gravity (CG) to ensure safe handling, efficient fuel use, and compliance with strict aviation regulations. To achieve this, engineers often rely on balance weights—and increasingly, tungsten alloys are becoming the material of choice.

What Are Balance Weights in Aircraft?

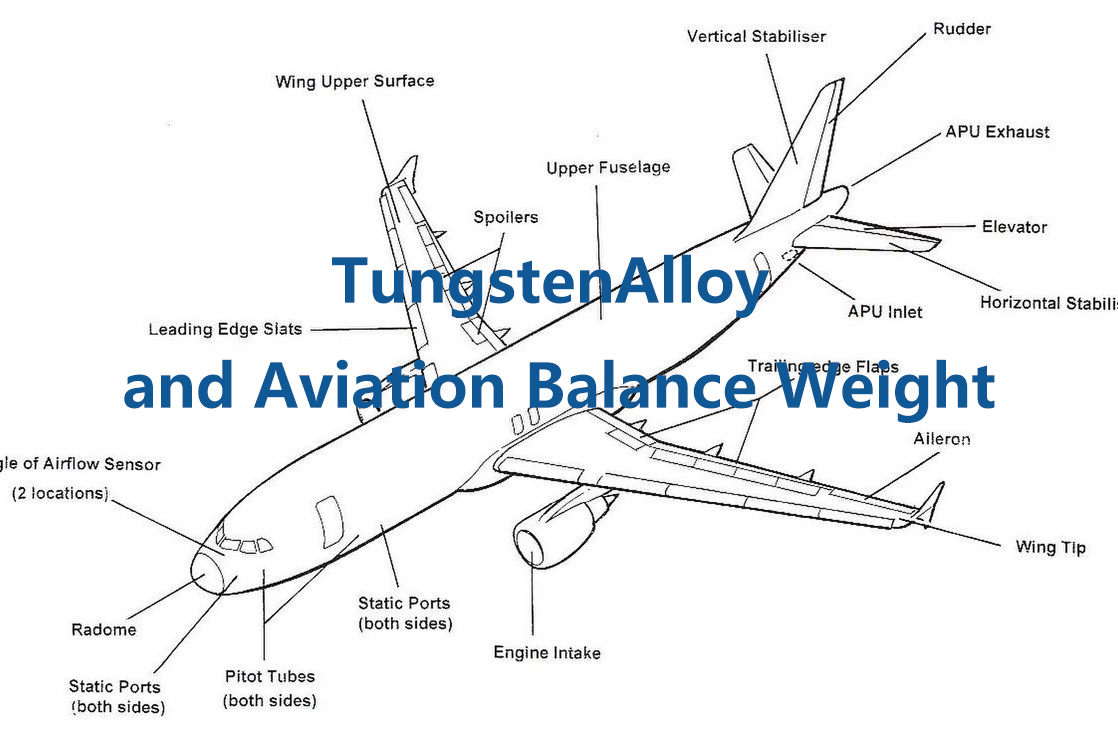

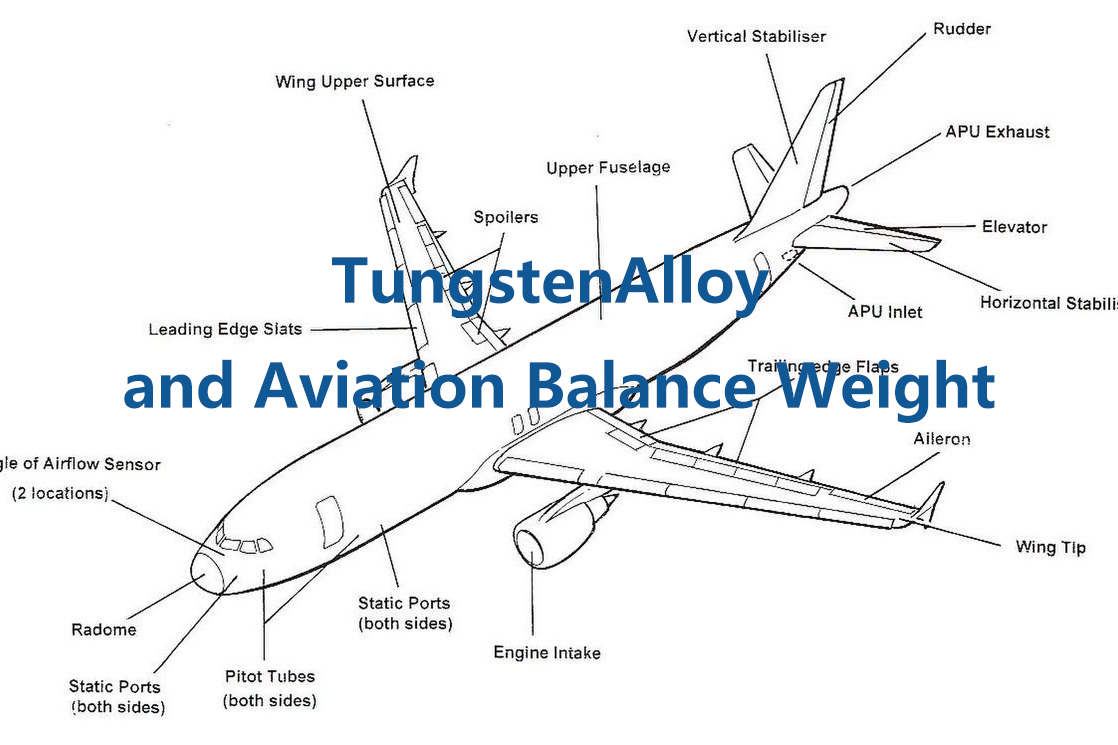

Balance weights, also called counterweights or trim weights, are strategically placed masses used to:

- Maintain proper center of gravity

- Balance control surfaces like ailerons, rudders, and elevators

- Minimize vibration and prevent flutter at high speeds

- Adjust for asymmetries caused by fuel, cargo, or onboard equipment

In short, they help aircraft fly safely, smoothly, and efficiently.

Why Use Tungsten Alloys?

Tungsten alloys offer a unique combination of properties that make them especially well-suited for balance weight applications:

1. High Density (Up to 18.5 g/cm³)

Tungsten alloys are among the densest engineering materials available—much denser than steel (~7.8 g/cm³) and significantly denser than lead (~11.3 g/cm³). This allows:

- Smaller counterweights for the same mass

- More design flexibility in tight spaces

- Lower aerodynamic drag and better packaging

2. Excellent Mechanical Strength

Tungsten alloys maintain their strength at high temperatures and under mechanical stress—ideal for high-performance aerospace environments, including jet engines and wing assemblies.

3. Corrosion Resistance

Tungsten alloys are highly resistant to oxidation and chemical degradation, making them ideal for long-term use in harsh flight conditions.

4. Non-toxic and RoHS Compliant

Unlike lead, tungsten alloys are non-toxic and environmentally compliant, meeting RoHS and REACH standards for aerospace sustainability.

Typical Aerospace Applications of Tungsten Balance Weights

|

Aircraft Component |

Function of Tungsten Weight |

|

Flight Control Surfaces |

Mass balancing of ailerons, elevators, and rudders |

|

Rotor Blades (Helicopters) |

Vibration dampening and dynamic balancing |

|

Satellites and Missiles |

Center-of-mass adjustment for flight stability |

|

Nose/Empennage Areas |

Trim and CG adjustments for fuel and payload shifts |

|

Avionics and Instruments |

Balance of moving parts in gyroscopes or gimbals |

Tungsten weights are even used in spacecraft, where microgravity and zero margin for error require extremely compact and precise mass distribution.

Case Study: Commercial Jet Stabilization

In large commercial aircraft, center of gravity shifts as fuel burns or cargo is redistributed. Airlines use modular tungsten alloy balance weights to fine-tune load distribution. These can be integrated into the tail cone, winglets, or undercarriage assemblies, without affecting aerodynamics.

Tungsten Alloys vs. Other Materials for Aviation Balance Weights

Tungsten alloys offer the highest density among commonly used materials, ranging from 17 to 18.5 g/cm³. This allows engineers to place more mass in less space compared to lead (11.3 g/cm³), steel (7.8 g/cm³), or titanium (4.5 g/cm³), enabling better weight distribution in tight areas like wing tips or tail sections.

In terms of mechanical performance, tungsten alloys provide high tensile strength (around 700–1000 MPa), excellent fatigue resistance, and thermal stability. These properties make them suitable for high-vibration zones such as rotor tips or control surface linkages. In contrast, lead deforms easily and is not suitable for structural loads, while steel, though strong, requires more space due to its lower density.

Tungsten is also non-toxic and fully compliant with RoHS and REACH regulations, making it a safer and more sustainable option than lead, which is increasingly restricted due to its toxicity. Steel is safe but less efficient when space or weight reduction is critical.

In corrosive environments, tungsten alloys—especially when alloyed with nickel or iron—are highly resistant to oxidation, unlike lead, which forms toxic oxides, or steel, which requires protective coatings to prevent rust.

Although tungsten alloys are more expensive, their superior performance, space efficiency, and regulatory compliance often justify the cost, especially in aerospace applications where weight, safety, and precision are paramount.

Related reading: Why Do F1 Racing Engines Use Tungsten Alloy Crankshafts?

|

Factor |

Lead |

Steel |

|

|

Density (g/cm³) |

17–18.5 |

11.3 |

7.8 |

|

Volume Efficiency |

✅ Excellent |

⚠️ Moderate |

❌ Poor |

|

Structural Strength |

✅ High |

❌ Low |

✅ High |

|

Toxicity |

✅ Safe |

❌ Toxic |

✅ Safe |

|

Corrosion Resistance |

✅ Very Good |

❌ Poor |

⚠️ Moderate |

|

Regulatory Compliance |

✅ Fully Compliant |

❌ Restricted |

✅ Compliant |

|

Best Use Case |

Precision aerospace |

Legacy systems |

Non-critical mass |

Why Choose ARM’s Tungsten Counterweights?

- Maximum density in minimal space, ideal for constrained aerospace components.

- High mechanical strength, ensuring durability under vibration and thermal stress.

- Non-toxic and compliant with RoHS/REACH environmental regulations.

- Customizable to meet exact CAD drawing specifications.

- Proven experience: Advanced Refractory Metals has over 20 years supplying high-quality precision tungsten components.

Conclusion

As aircraft designs become more compact, efficient, and high-performing, the need for dense, strong, and corrosion-resistant counterweight materials continues to grow. Tungsten alloys meet these demands better than traditional alternatives like lead or steel, making them the preferred solution for modern aviation balance weights.

Whether in commercial jets, military aircraft, rotorcraft, or spacecraft, tungsten’s unmatched density and stability are helping engineers keep flight on the straight and level. For more tungsten alloy products, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}