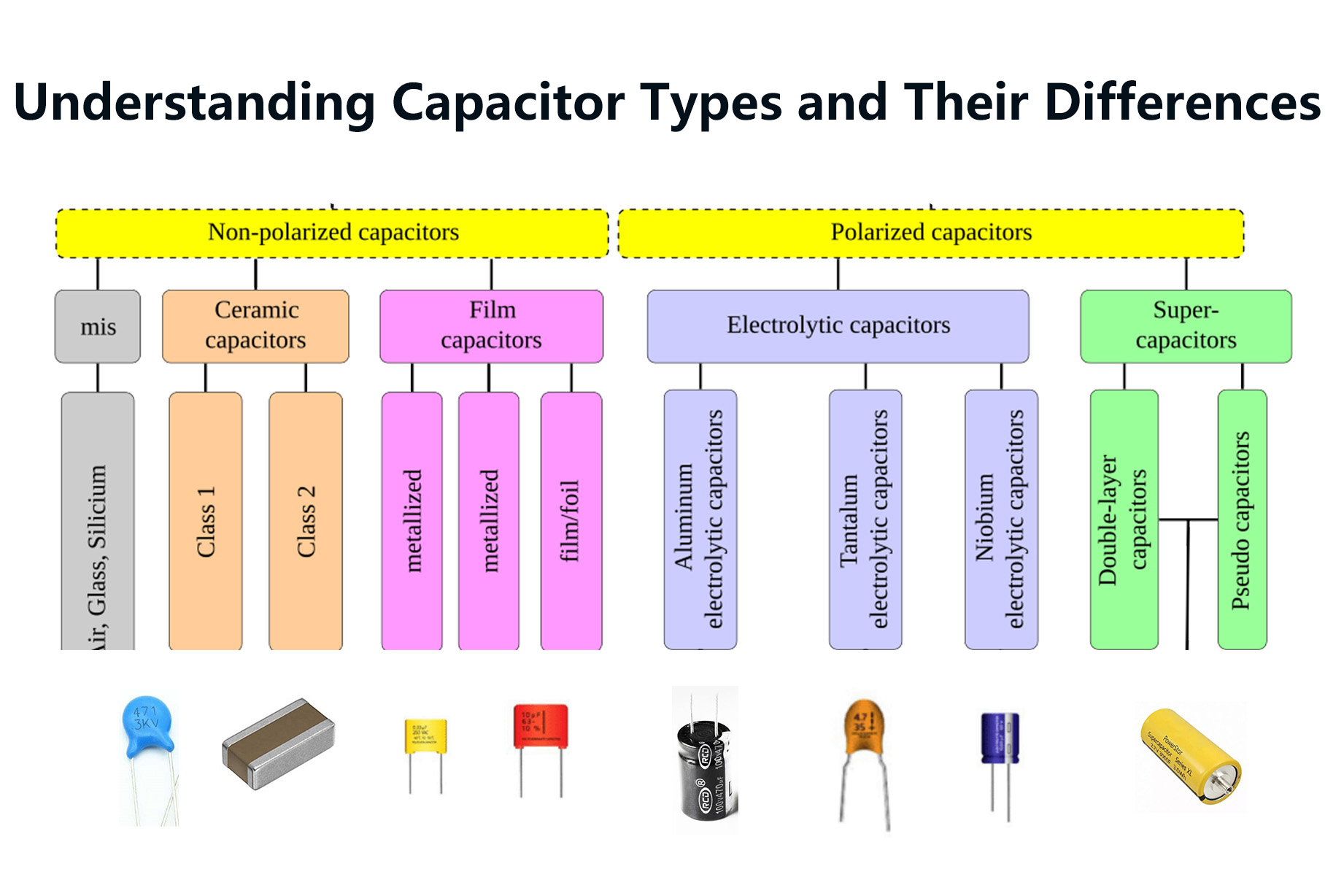

Understanding Capacitor Types and Their Differences

What Is A Capacitor?

A capacitor is a passive electronic component consisting of two conductive plates separated by an insulating material called the dielectric. Electric charge accumulates when a voltage is applied across the plates, and an electric field is established. The unit of measure of the ability of a capacitor to store charge is in farads (F), and the stored charge depends on the surface area of the plates, the distance between the plates, and the dielectric material.

Whereas resistors oppose current flow and dissipate energy as heat, capacitors store electrical energy temporarily. They find application in a wide range of electronic applications, including power supply output smoothing, signal filtering, coupling or decoupling of signals between amplifier stages, and timing circuits.

Common Types of Capacitors and Their Dielectrics

Capacitors are differentiated based on their dielectric material, which basically influences their performance and usability in applications. The following are the broad categories:

1. Ceramic Capacitors

Ceramic capacitors are the most widely produced capacitors in the electronics industry, with more than one trillion pieces made annually. They are compact, low-cost, and have a wide range of available capacitances, typically ranging from a few picofarads (pF) to 10 microfarads (µF).

They are non-polarized and can be used in AC as well as DC circuits. They have a simple construction with ceramic material as the dielectric and silver coatings on both sides as the electrodes.

More recent versions, known as Multi-Layer Ceramic Capacitors (MLCCs), stack multiple layers of ceramic to achieve greater capacitance in a small footprint. MLCCs are called the "industrial rice" due to their prevalence in products like smartphones, laptops, and automotive control units.

2. Electrolytic Capacitors

Electrolytic capacitors are the preferred type where high capacitance in a small package is required, such as in power supply filtering. They consist of a metal anode (typically aluminum, tantalum, or niobium) with an oxide layer as the dielectric and an electrolyte as the cathode.

They are divided based on the dielectric material:

- Aluminum Electrolytic Capacitors: Widely used, reasonably priced, but with modest life and stability.

- Tantalum Electrolytic Capacitors: Compact, stable, and reliable, with capacitance values from 47 nF to 470 µF and voltage ratings up to 50 V.

- Niobium Electrolytic Capacitors: Less common, offering the same benefits as tantalum types.

Among these, tantalum capacitors use tantalum pentoxide (Ta₂O₅) for the dielectric and are characterized by their stability, reliability, and compactness. Tantalum capacitors possess lower leakage current and better stability of capacitance compared to aluminum electrolytics but at a higher cost.

They must be carefully used in high inrush current circuits because they will fail if not handled properly.

Further reading: Tantalum Capacitors: A Comprehensive Guide

3. Film Capacitors

Film capacitors utilize plastic film (such as polyester, polypropylene, or PTFE) as the dielectric and are non-polarized. They typically comprise two metal electrodes with a dielectric film wrapped in a cylindrical shape between them.

They boast low equivalent series resistance (ESR), low parasitic inductance, and good long-term and temperature stability. These qualify them for high-frequency applications, AC signal filtering, and precision timing.

The direct connection between terminals and internal winding ensures short current paths and good performance, especially where signal integrity is critical.

Summary Table

|

Capacitor Type |

Dielectric Material |

Polarity |

Key Advantages |

Common Applications |

|

Ceramic Capacitor |

Ceramic (e.g., barium titanate) |

Non-polarized |

Compact, low cost, wide frequency response, stable MLCC options |

Decoupling, filtering, general-purpose electronics |

|

Aluminum Electrolytic |

Oxide layer on aluminum |

Polarized |

High capacitance per volume, inexpensive |

Power supply filters, audio equipment |

|

Tantalum Electrolytic |

Tantalum pentoxide (Ta₂O₅) |

Polarized |

Stable, compact, low leakage current, better temperature stability than aluminum |

Timing, decoupling, filtering, portable electronics |

|

Niobium Electrolytic |

Niobium pentoxide |

Polarized |

Similar to tantalum, more availability, cost-effective alternative |

Similar to tantalum applications |

|

Film Capacitor |

Plastic films (polyester, polypropylene, PTFE) |

Non-polarized |

Low ESR, high stability, low inductance, long life |

AC filtering, high-frequency circuits, timing |

For more electronic materials, please check Advanced Refractory Metals (ARM).

How to Choose the Right Capacitor

Choosing the correct capacitor requires consideration of several important parameters:

- Capacitance Value: Must meet the application's energy storage or filtering need.

- Voltage Rating: The highest voltage the capacitor can safely withstand.

- Physical Size: Important for fitting small PCBs, especially in portable electronics.

- Leakage Current: Important for low-power circuits.

- Equivalent Series Resistance (ESR): Low ESR is important in high-frequency circuits to minimize losses.

- Polarity: Some capacitors (e.g., electrolytic) are polarized and must be correctly oriented in the circuit.

Final Thoughts

Understanding the subtleties of types—ceramic, electrolytic, tantalum, and film—is crucial to the creation of reliable, efficient electronics. With the demands of miniaturization, power efficiency, and signal integrity on the rise, so too is the requirement to choose the most suitable capacitor for the application.

Reference:

[1] Capacitor types. (2025, June 30). In Wikipedia. https://en.wikipedia.org/wiki/Capacitor_types#

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}