Which Is Better: Tungsten Wire vs. Molybdenum Wire

The most commonly chosen metals for such extreme environments are tungsten and molybdenum. Both belong to the same group in the periodic table and exhibit a range of similar properties, including strength, high resistance to temperature, and durability. Yet, their identified differences make each more conducive to specific industrial applications. One will decide upon either tungsten wire or molybdenum wire based on unique demands for one's project: whether it is temperature tolerance, mechanical strength, electrical conductivity, or weight considerations.

Tungsten Wire vs. Molybdenum Wire: Material Properties

Melting Point and High-Temperature Stability

One of the most distinctive differences between tungsten and molybdenum involves their melting points-a preeminent factor when it comes to high-temperature uses.

- Tungsten boasts the highest melting point among metals, standing at 3,422°C/6,192°F. This extreme resistance to heat makes the wire a perfect fit for applications that involve very high temperatures and require the components to perform their functions without deterioration for extended periods. In applications related to lighting, including incandescent bulbs and lamps, for example, tungsten filaments can endure the high temperatures required for light production without melting or losing structural integrity.

- Molybdenum has a melting point of 2,623°C (4,753°F ), which is very highly resistant to heat. While it is adequate and often applied in many industries, both industrially and in aerospace, it cannot compete in scenarios where extreme temperature conditions are required. This lower melting point makes molybdenum better placed in applications needing high heat but not to such extreme levels.

Mechanical Strength and Durability

• Tungsten wire exhibits very high mechanical strength. Tungsten is considered one of the hardest metals, as its tensile strength can reach up to 1,500 MPa. Therefore, tungsten is ideal for applications requiring more extreme conditions where components may be subjected to mechanical stress, such as rocket nozzles, high-performance turbines, and vacuum tubes.

• Molybdenum wire is not as strong as tungsten but, nonetheless, very strong, in the range between 500 MPa and 900 MPa. This strength, combined with the higher ductility, makes molybdenum more suitable for applications that require some flexibility or bending. Whereas tungsten wire may break or fracture under bending stresses, molybdenum wire can be easily bent and shaped without loss of integrity.

Electrical Conductivity

• Tungsten has relatively poor electrical conductivity compared to metals such as copper. However, it still manages to play a significant role in electrical discharge applications. When considering the usability of tungsten wire in vacuum tubes, light bulbs, and electrodes, resistance to electrical current and the capability to generate heat is usually more imperative than good conductivity.

• Molybdenum possesses better electric conductivity compared to tungsten. For this reason, it is preferred in high voltage applications and electrical contacts where the transfer of energy is of higher importance. Molybdenum wire is used in space electronics, semiconductor devices, solar panel construction, and other applications that involve a combination of conductivity and high thermal resistance.

Corrosion Resistance and Durability

Tungsten has very good resistance to oxidation and corrosion, especially at high temperatures, making it ideal for use in harsh, high-heat environments, such as those found in spacecraft components and welding applications.

Molybdenum is also very resistant to corrosion; however, it is said to act somewhat better under mild to moderate temperature conditions. It is often used in applications related to exposure to acidic environments and high-temperature chemical processes.

Manufacturing and Cost Comparison

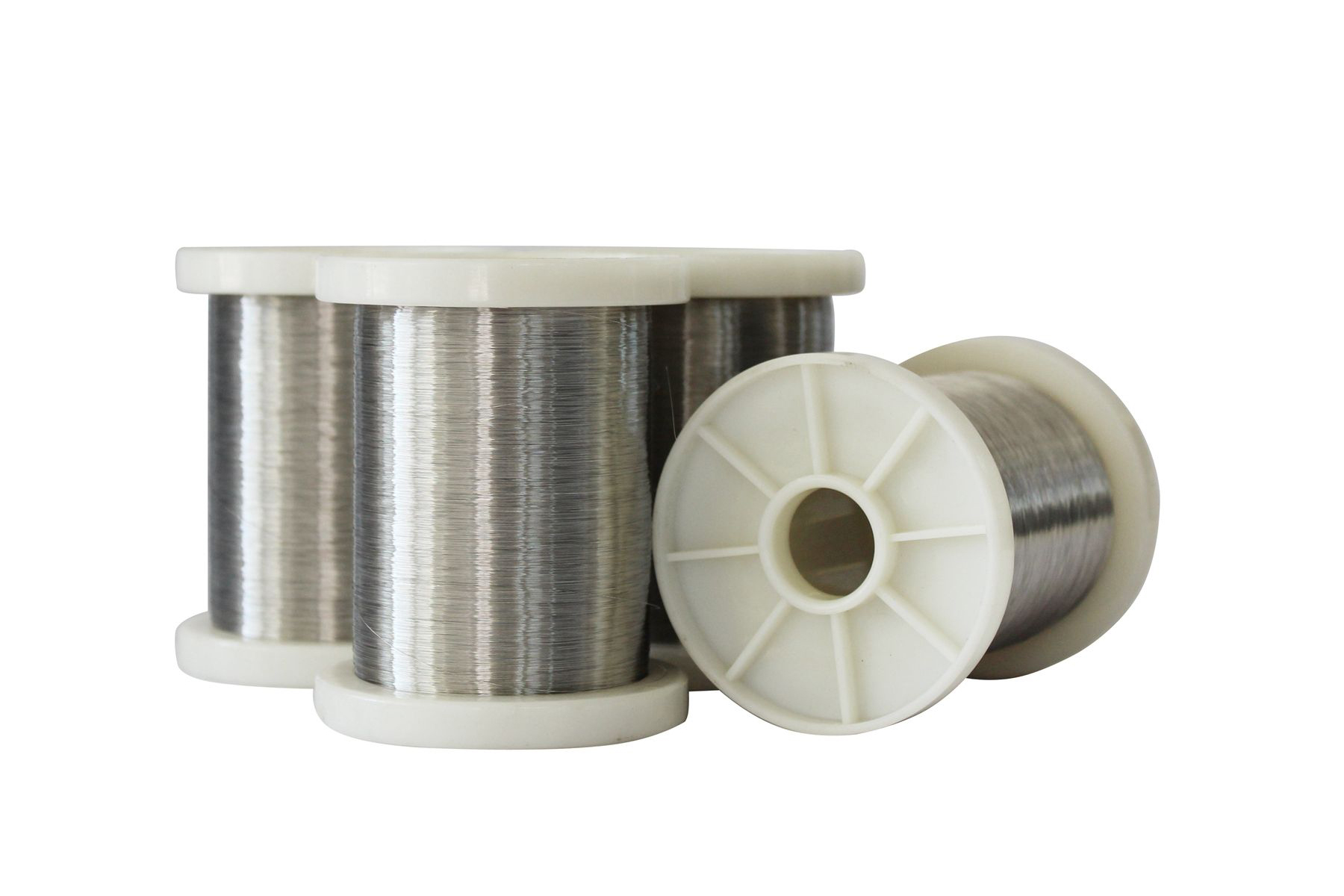

Tungsten Wire

Manufacturing of tungsten wire is a very complicated and energy-intensive process because of its hardness and high melting point. Essentially, it is manufactured from tungsten powder, which is compressed, sintered, and then drawn into wire form. Specialized equipment is required for this process because of the high temperature it undergoes when turning tungsten into wire form. Because of the intensive production process, tungsten wire is thus produced in small batches, making it even more costly than molybdenum wires.

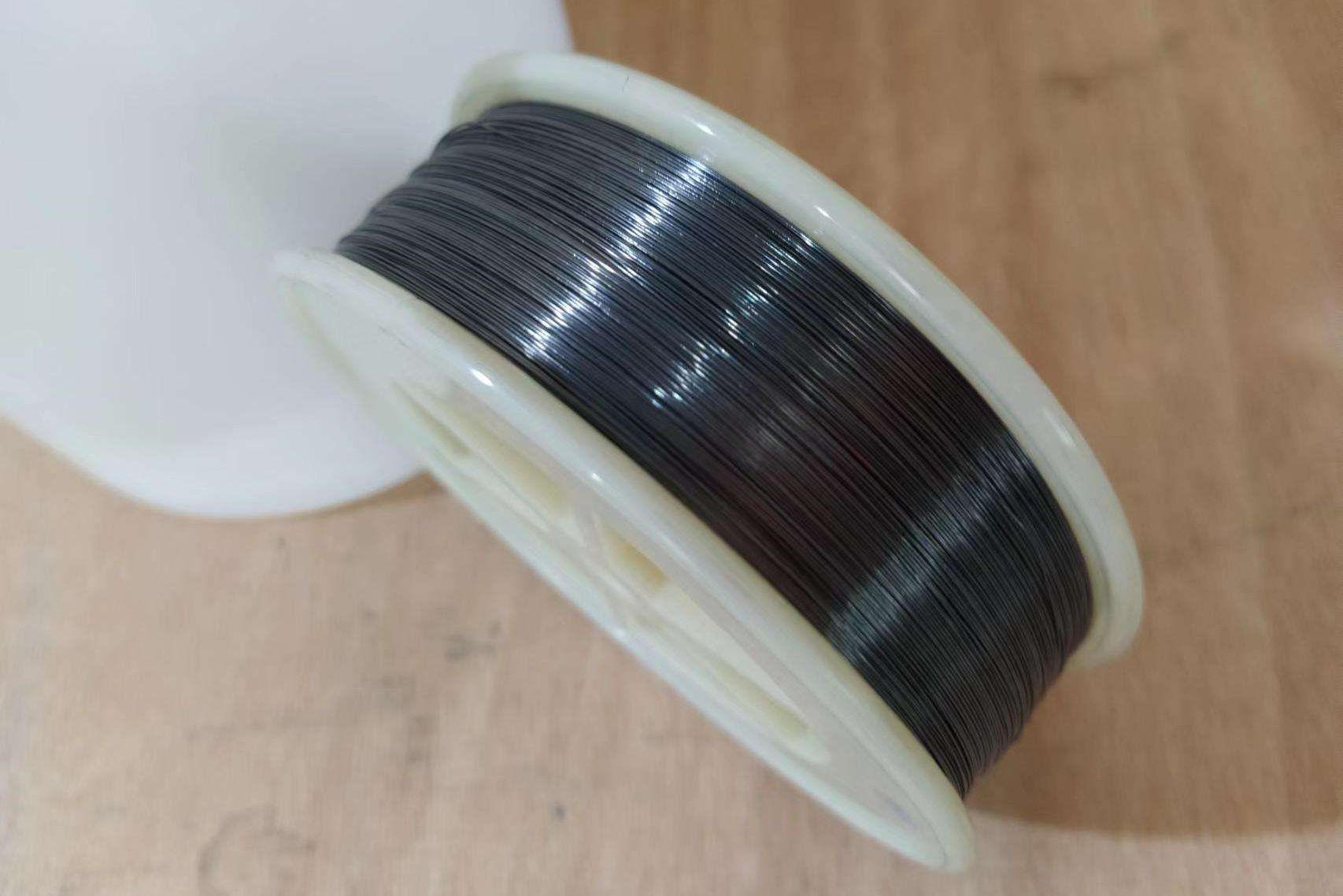

Molybdenum Wire

Molybdenum wire is easier to make than tungsten wire. Molybdenum has a lower melting point, and its higher ductility makes it easier to draw into a wire. Therefore, molybdenum wire requires less energy and equipment for processing, thus is cheaper and faster in production. This would mean that molybdenum wires are more cost-effective for industries that need higher volumes or have other budgetary constraints.

Applications: Where Tungsten and Molybdenum Wire Excel

Tungsten Wire Applications

Owing to its extremely high melting point and mechanical strength, tungsten wires are widely used in applications requiring materials to withstand extremely high temperatures and mechanical tensions. Typical applications include:

- Lighting: Tungsten wire is used as the operating material for incandescent light bulbs, halogen lamps, and high-intensity discharge lamps. In these applications, the great resistance that tungsten has to degradation at high temperatures is critical in generating long-lived and efficient lighting.

- Aerospace: Tungsten wire in satellite components, spacecraft, and rocket nozzles is used where its ability to endure extreme thermal conditions and mechanical stresses is crucial.

- Electronics: Tungsten wires function well in vacuum tubes, electron guns, and cathodes under high current and vacuum conditions.

- Welding: In TIG welding, also known as Tungsten Inert Gas welding, tungsten electrodes are necessary; the wire must bear high temperatures and not lose its strength during this process.

Related reading: What Are the Main Uses of Tungsten Wire?

Molybdenum Wire Applications

Molybdenum wire is superior for applications that require good thermal and electrical performance-but not extreme performance-due to its higher electrical conductivity and lower cost. Typical applications of the metal consist of:

- Electrical Contacts: It finds usage in high voltage electric appliances such as switches, relays, and circuitry because molybdenum wire is highly conductive, and thermal stability makes it ideal for power transmission.

- Aerospace: Molybdenum wire is also used in aerospace applications, but in areas where the temperature demands are slightly less intense than those that require tungsten. Consequently, molybdenum, with its lightweight and resilient properties, can easily be applied to aerospace structures, high-speed aircraft, and satellite parts.

- Semiconductors: Molybdenum wires have widespread application in semiconductor manufacturing and electronics for their use in sputtering targets and electrodes, due to the excellent thermal and electrical properties at moderate temperatures.

- Medical Devices: Molybdenum wire finds applications in the making of medical equipment like radiation shielding and surgical tools because of its resistance to corrosion and biocompatibility.

How to Choose Tungsten Wire or Molybdenum Wire

The decision between tungsten wire and molybdenum wire primarily depends on the exact requirements of your application:

• Choose Tungsten Wire when the job requires extreme heat resistance, strength, and durability in high-stress or high-temperature applications. Tungsten has a broad applicability in high-temperature lighting, in space exploration, and in a number of arc-welding applications.

• Molybdenum Wire: Select Molybdenum Wire for applications that require cost efficiency, good electrical conductivity, and moderate temperature resistance. The molybdenum wire is ideal for electrical contacts, aerospace, and semiconductor applications since it requires heat tolerance but not necessarily for extreme temperatures. For more refractory metal products, please check Advanced Refractory Metals (ARM).

In conclusion, both tungsten and molybdenum wires have properties that set them apart; however, tungsten wire is best suited for high-performance, high-temperature applications, while molybdenum wire represents a versatile, generally lower-cost solution for a wide variety of industrial and electrical applications. Consider the specific temperature, strength, and conductivity demands of the application in question, and you will be sure to make the right choice for your materials.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}