What Materials Are Used for Rocket Nozzles?

Rocket nozzles are among the most critical components in propulsion systems, responsible for converting the thermal energy of combustion gases into directed kinetic energy that produces thrust. To perform this role, they must withstand extraordinary conditions: extreme heat, rapid temperature fluctuations, corrosive combustion products, and intense mechanical stresses.

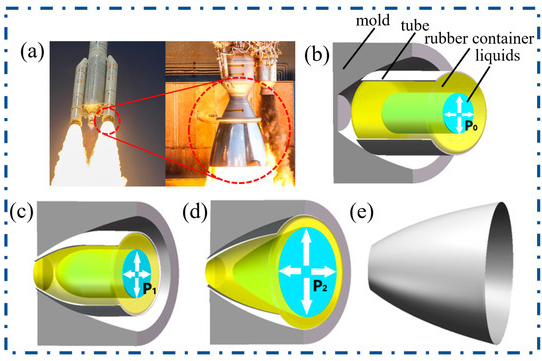

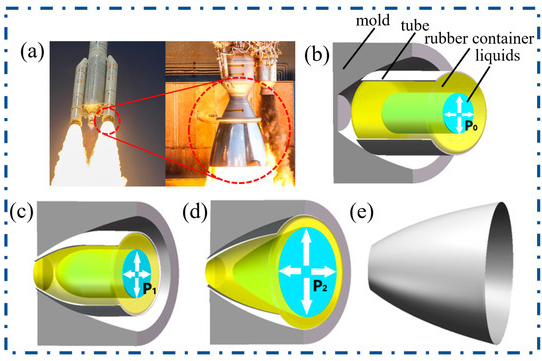

[1]

The Thermal and Mechanical Challenge

During flight, rocket nozzles are exposed to gas temperatures in excess of 3,000 °C, many times above the melting point for any structural metal. Supersonically flowing combustion gases erode and chemically degrade surfaces. The material of the nozzle must resist:

- Thermal stresses: caused by high temperature gradients between the hot internal wall and cooler external structure.

- Creep and fatigue: from repeated exposure to high stress at elevated temperatures.

- Oxidation and corrosion: resulting from hot, oxygen-rich combustion gases.

- Erosion: resulting from high-velocity particle-laden flow.

No single material is able to meet every requirement perfectly, therefore engineers utilize a combination of high-performance metals, ceramics, composites, and thermal protection systems.

Further reading: Something to Know About Rocket Nozzles

Rocket Nozzle Material 1: Refractory Metals

--Niobium and Niobium Alloys

Niobium alloys such as C-103 (Nb-10Hf-1Ti) are widely used for nozzles in smaller chemical rockets and space propulsion systems. They offer:

- High melting point (~2470 °C).

- Good ductility and toughness compared to other refractory metals.

- Relative ease of fabrication by forging, machining, and welding.

However, niobium oxidizes rapidly in air above ~400 °C. As a result, it requires protective coatings, typically silicide or ceramic layers, to prevent oxidation during operation. Niobium-based nozzles are common in satellite thrusters and upper-stage engines where long burn times and vacuum operation minimize oxidative exposure.

--Molybdenum and Molybdenum Alloys

Molybdenum and Mo-Re (molybdenum-rhenium) alloys are valued for creep resistance and strength at high temperatures. With a melting point of 2623 °C and excellent thermal conductivity, they help manage heat flow. Like niobium, molybdenum requires coatings to resist oxidation and is often used in staged-combustion or vacuum-optimized engines.

--Tungsten

Tungsten has the highest melting point of all metals (3422 °C) and exceptional erosion resistance, making it ideal for throat inserts, the most thermally stressed part of the nozzle. Tungsten is brittle at room temperature, but alloying with rhenium (W-Re) improves ductility and fabricability. Tungsten-rhenium inserts are used in engines like the Apollo Lunar Module Descent Engine, where reliability under extreme heating was paramount.

Rocket Nozzle Material 2: Superalloys

Nickel-based superalloys are widely employed in rocket nozzles, especially in regeneratively cooled designs. These alloys combine:

- High tensile strength at elevated temperatures.

- Resistance to oxidation and corrosion.

- Good fabricability, including welding and machining.

In regeneratively cooled nozzles, superalloys are formed into channels through which cryogenic fuel circulates, cooling the nozzle while preheating the propellant. Engines like the Space Shuttle Main Engine (SSME) used nickel-based alloys extensively for this reason.

Rocket Nozzle Material 3: Carbon-Carbon Composites

Carbon-carbon composites (C/C) are made by reinforcing carbon fibers with a carbon matrix and graphitizing the structure. These materials withstand temperatures above 3,000 °C in non-oxidizing environments, making them ideal for solid rocket motor nozzles and throat sections.

Advantages include:

- Very high sublimation temperature.

- High thermal shock resistance.

- Low density compared to refractory metals.

Their limitation is vulnerability to oxidation; thus, protective coatings such as silicon carbide or zirconium carbide are often applied. The Space Shuttle’s Solid Rocket Boosters used carbon-carbon composite inserts in nozzle throats.

Rocket Nozzle Material 4: Ceramics and Ceramic Matrix Composites (CMCs)

Advanced ceramics such as zirconia (ZrO₂), and silicon carbide (SiC) offer exceptional resistance to high-temperature corrosion and erosion. When reinforced into ceramic matrix composites (CMCs), they combine the strength and toughness of fibers with the thermal stability of ceramics.

Applications include:

- Nozzle extensions for upper-stage engines.

- Thermal protection coatings.

- Hybrid ceramic-metal designs to reduce mass while maintaining durability.

While ceramics are inherently brittle, fiber reinforcement and layered architectures mitigate this issue.

Rocket Nozzle Material 5: Ablative Materials

In many rocket motors—particularly solid propellant boosters—ablative materials form the inner nozzle lining. Instead of resisting heat indefinitely, ablatives sacrifice themselves, gradually eroding and carrying heat away in the process.

Common ablatives include:

- Phenolic-impregnated carbon (PIC).

- Carbon-phenolic composites.

- Epoxy or silica-based composites.

These materials are relatively inexpensive and effective for short-duration, high-thrust burns such as launch boosters. The nozzle of NASA’s Saturn V F-1 engine, for instance, used ablative liners to protect structural components from extreme heat.

Conclusion

Rocket nozzles embody the art of materials engineering under extreme conditions. From refractory metals like niobium and tungsten to superalloys, composites, ceramics, and ablatives, each material class brings unique strengths and limitations.

Refractory metals provide unmatched temperature resistance but require protective coatings. Superalloys enable regenerative cooling and robust fabrication.Carbon-carbon composites and ceramic composites push performance in high-temperature, high-radiation environments. Ablatives remain practical solutions for short, intense missions. For more refractory metal products, please check Advanced Refractory Metals (ARM).

Reference:

[1] Chen, Y.; Zhao, S.; Wang, H.; Li, J.; Hua, L. Theoretical Analysis and Verification on Plastic Deformation Behavior of Rocket Nozzle Using a Novel Tube Upsetting-Bulging Method. Materials 2023, 16, 1680. https://doi.org/10.3390/ma16041680

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}