Something to Know About Rocket Nozzles

Rocket nozzles are essential to rocket propulsion systems. They take the hot gases produced by the engine and turn them into thrust that pushes the rocket forward. The nozzle's design, the materials, and how it’s cooled all affect its performance. Let's dive into the basics.

How Do Rocket Nozzles Work?

At the heart of it, rocket nozzles operate on a simple idea: Newton’s Third Law of Motion. When a rocket burns fuel, it creates hot gases. These gases shoot through the nozzle, and the nozzle’s shape speeds them up. The faster these gases leave the nozzle, the more thrust the rocket gets. A nozzle typically has a narrow throat that speeds up the gas, followed by a wider exit where the gases expand and gain even more speed. This process is critical to getting the most thrust out of the rocket.

Related reading: Tungsten Copper Alloy for Rocket Throat Lining

Why Are Rocket Nozzles Bell-Shaped?

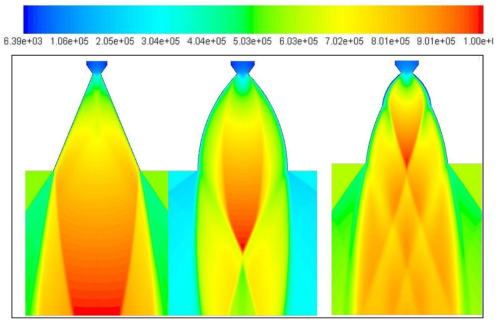

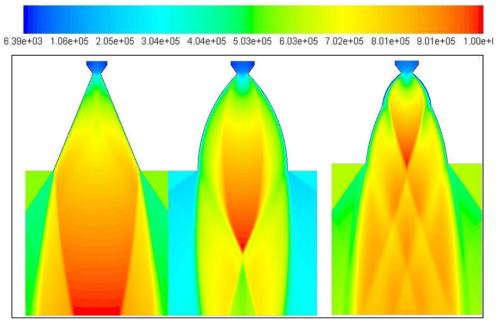

If you’ve seen a rocket, you’ve probably noticed the bell-shaped nozzles. There’s a good reason for that shape. The bell nozzle is an example of a converging-diverging nozzle, which is great for controlling the flow of exhaust gases. The narrow part of the nozzle, or the throat, speeds up the gases to supersonic speeds. Then, as the gases expand in the wider section, their pressure drops, and they leave the nozzle at higher speeds. This helps the rocket generate the most thrust while keeping the exhaust flow smooth and efficient.

However, the bell shape is best at a specific altitude. If the rocket is flying at different altitudes, the nozzle’s efficiency can change.

[1]

[1]

Fig. 1 Pressure contours for conical, bell nozzle, and dual bell nozzle at 50,000 ft and Mach 2.5.

How to Prevent Rocket Nozzles from Melting?

Rocket nozzles are exposed to temperatures that can easily exceed 3,000°F (1,650°C). So, how do they manage not to melt? The answer lies in the materials used and the cooling systems built into the nozzles. Many nozzles are made of heat-resistant materials. On top of that, cooling systems are used to help keep things from overheating. One common method is regenerative cooling, where fuel flows through channels in the nozzle before reaching the engine. Some nozzles use ablative cooling, where the outer layer of the nozzle gradually burns away, carrying heat with it. This allows the inner part of the nozzle to stay cooler.

Types of Rocket Nozzles

There are different types of rocket nozzles. Here are the three most common:

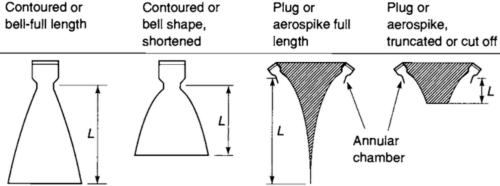

- Conical Nozzle: This is the simplest design, where the nozzle walls diverge at a steady angle. The conical nozzle was often used in early rocket designs because it’s easy to make. A smaller angle gives better performance by maximizing the velocity of the exhaust gases. However, this design leads to a heavier and longer nozzle, which can be a drawback. Larger angles, while lighter, reduce performance at lower altitudes due to issues like overexpansion and flow separation.

- Bell Nozzle: This is the most widely used design today. The bell nozzle balances performance and size. It starts with a relatively large divergence angle near the throat, but the divergence becomes smaller as you move downstream. This shape helps to minimize the nozzle’s weight while still ensuring high performance. The goal in designing a bell nozzle is to avoid oblique shocks and ensure the gases flow smoothly. It works best at a certain altitude, but its performance can be adjusted for different environments.

- Annular Nozzle: Also known as the plug nozzle, this design is more complex and less commonly used. The annular nozzle features combustion around a central ring, and it includes a central plug that obstructs the center of the nozzle. Its main advantage is that it compensates for changes in altitude, making it ideal for rockets that need to operate in varying atmospheric conditions. However, this design adds complexity, making it more challenging to manufacture and less common than the simpler bell or conical nozzles.

[2]

[2]

Fig. 2 Different Nozzle Configurations

Materials Used for Rocket Nozzles

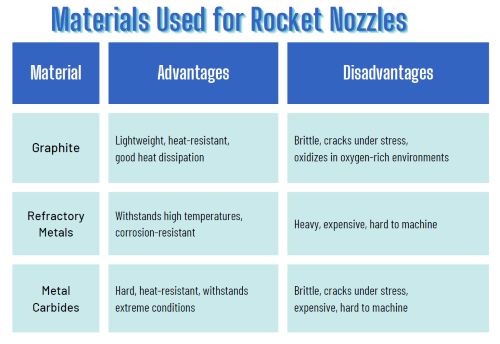

Nozzles are typically made from graphite, refractory metals, or metal carbides to face extreme heat.

- Graphite: A popular choice for lightweight, thermally efficient designs. It can handle temperatures over 3,000°C (5,432°F) and dissipates heat well. However, graphite is brittle and can crack under stress or thermal shock, so it needs to be handled carefully. It can also oxidize in oxygen-rich environments, so it’s often coated with protective layers.

- Refractory Metals: Metals like tungsten, molybdenum, and tantalum are known for their ability to withstand extremely high temperatures, often exceeding 3,000°C (5,432°F). These metals maintain their strength under heat and also offer good resistance to corrosion. However, they are heavier than graphite and expensive to manufacture and machine.

- Metal Carbides: Tungsten carbide and silicon carbide are known for their incredible hardness and heat resistance. These materials can handle extreme conditions, maintaining their structural integrity at temperatures above 3,000°C (5,432°F). However, metal carbides are brittle and can crack under stress. Like refractory metals, they are also expensive and difficult to machine.

Fig. 3 Materials Used for Rocket Nozzles

Conclusion

Rocket nozzles are vital components of a rocket’s propulsion system. The choice of nozzle type and materials can significantly affect the efficiency, cost, and performance of the rocket. For more information, please check Advanced Refractory Metals (ARM).

Referemce:

[1] Baidya, Raman & Pesyridis, Apostolos & Cooper, Maxim. (2018). Ramjet Nozzle Analysis for Transport Aircraft Configuration for Sustained Hypersonic Flight. Applied Sciences. 8. 574. 10.3390/app8040574.

[2] van t Klooster, Thomas. (2016). Quantum Launch System. 10.13140/RG.2.2.34320.20480.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}