Types of Capillary Tubes: A Detailed Guide

Capillary tubes are small-diameter tubes used extensively in fluidic systems to control and measure the flow of liquids and gases. Due to their fine internal diameter—often less than 2 mm—they are ideal for applications that require precise metering, pressure drop control, or the facilitation of capillary action. These tubes play essential roles in fields ranging from HVAC systems and medical diagnostics to chromatography and laboratory instrumentation. Here are the main types of capillary tubes.

1. Material-based Types

a. Glass Capillary Tubes

Glass capillary tubes are typically fabricated using borosilicate or soda-lime glass. Both of these materials provide excellent transparency and chemical resistance, and hence are suitable for visual and laboratory use.

In schools, they are employed as demonstrators of capillary action in physics and biology practicals. They are also applied in microfluidic research due to the fact that they exhibit a consistent flow regime and their inert nature. They are ubiquitously used in clinical laboratories to calculate hematocrit, where the proportion of red blood cells in a given blood sample is quantified with them.

b. Metal Capillary Tubes

Metal capillary tubes consist of various metals like stainless steel, copper, nickel, and titanium. They are known for their strength, corrosion resistance, and the capacity to withstand high temperatures and pressures.

They are heavily utilized in industrial and mechanical devices. Copper capillary tubes, for instance, are used extensively in refrigeration and air conditioning systems due to their high thermal conductivity. Stainless steel tubes are also widely utilized in gas chromatography and pressure sensor systems because they are resistant and hard to corrosive conditions.

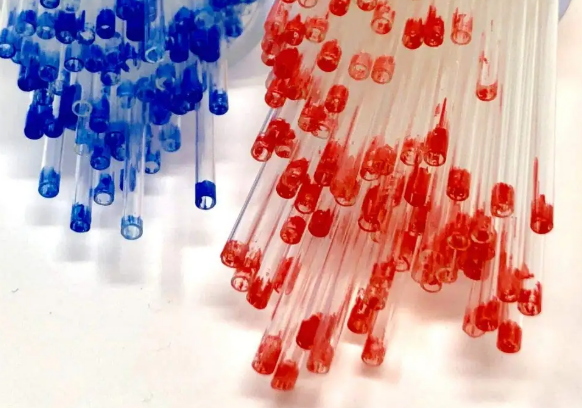

c. Polymer Capillary Tubes

Polymer capillary tubes are made up of a range of materials like PTFE (Teflon), PEEK (polyether ether ketone), nylon, and polyethylene. The tubes are useful in aspects like flexibility, better chemical resistance, and low internal friction, thus making them suitable for use in laboratory and medical applications.

They are universally used in chromatography systems—mainly high-performance liquid chromatography (HPLC)—with PEEK tubing controlling high pressure while maintaining chemical inertness. In medicine, polymer capillaries are used in devices like infusion pumps because of their flexibility and biocompatibility.

2. Structure-Based Types

a. Straight Capillary Tubes

Straight capillary tubes have a constant internal diameter and linear, unbent form. They have a simple geometry that reduces fluid flow uncertainty. They are suitable for laboratory use and for controlled fluid transfer. Straight capillary tubes are widely employed in industrial applications for controlling pressure across the condenser and evaporator in a refrigeration system. Their constant inner diameter provides predictable pressure drops and fluid delivery rates.

Copper straight capillary tubes are also used in home refrigerators to meter refrigerant from the high-pressure condenser to the low-pressure evaporator.

b. Coiled Capillary Tubes

Coiled capillary tube tubes are made by coiling the tube onto itself in a helical or spiral arrangement, which in effect increases the flow path length within a volume that is relatively small. This arrangement is particularly beneficial when space is limited or if an extended fluid path is required for pressure or temperature control.

These tubes have widespread use in refrigeration and HVAC systems to improve the pressure drop characteristics without occupying additional space. Coiled tubes are applied as delay loops or flow stabilizers for analytical systems like gas chromatography to condition the sample before analysis.

3. Application-Based Types

a. Refrigeration Capillary Tubes

Capillary tubes for refrigeration are utilized as expansion devices to regulate the pressure of refrigerants when moving from the condenser to the evaporator. By restricting flow, they reduce pressure and temperature, hence enabling efficient cooling.

These tubes are usually made of copper due to its superior heat conductivity, corrosion resistance, and fabricability. The setup is usually coiled so that it can have more length in the smallest space. The inner diameter and the total length are selected by the engineers based on the specific cooling capacity that the system requires.

For instance, a 0.031-inch internal diameter copper tube, around 5 feet long, is generally employed in household air conditioners to control refrigerant flow.

b. Medical Capillary Tubes

Medical capillary tubes are used in many clinical applications, including blood sampling, micro-volume liquid transfer, and precise measurement of bio-samples. The materials used are usually glass, which provides high transparency and sterilizability, or plastic, which provides low cost and disposability.

For instance, Heparin-coated micro-capillary tubes are widely used in neonatal intensive care unit (NICU) for rapid blood gas analysis from heel-stick blood samples.

c. Chromatography Capillary Columns

Capillary columns serve as a medium for separation of chemicals in chromatography. They are made from fused silica, PEEK (polyether ether ketone), or stainless steel, depending on the application of GC (gas chromatography) or HPLC (high-performance liquid chromatography).

Fused silica gas chromatography columns of 0.25 mm internal diameter and up to 60 meters in length are often used in volatile compound analysis in pharmaceutical and environmental lab settings.

d. Microfluidic Capillaries

Microfluidic capillaries are essential in lab-on-chip systems, where they control and transport small quantities of liquid—usually in the nanoliter to microliter range. Such tubes commonly employ capillary action rather than external pumps for moving fluids.

Glass and polydimethylsiloxane (PDMS) are most commonly used due to their biocompatibility, transparency, and microfabrication ease. The above capillaries make chemical and biological assays more feasible in miniaturized forms and offer faster and more convenient point-of-care diagnostics.

Glass microchannels in microfluidic chips are also used extensively in infectious disease screening rapid diagnostic kits and other biomedical assays.

Conclusion

Though very small, capillary tubes serve a gigantic purpose. Their accuracy at controlling fluid transport makes them omnipresent in a broad range of industries from cooling and chemical analysis to advanced medical diagnosis. Whether glass to ensure visibility in laboratories, copper to manage heat, or polymers for bio-incompatibility, each type plays an integral part in enabling precision, reliability, and efficiency in modern systems. For more capillary tubes, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}