5 Key Facts about Tantalum Mining

Tantalum is a rare, hard, blue-gray metal known for its corrosion resistance, high melting point, and excellent conductivity. Mining this strategic metal involves a global supply chain that combines geology, engineering, regulation, and ethics. Below are key facts about tantalum mining.

1. What Is Tantalum?

Tantalum (Ta, atomic number 73) is a transition metal prized for its stability under extreme conditions. It’s used primarily in the form of tantalum capacitors, which are compact, reliable, and essential for smartphones, computers, and automotive electronics. It’s also used in turbine blades, chemical processing equipment, and surgical implants due to its biocompatibility.

Related reading: 3 Common Tantalum Products and Their Applications

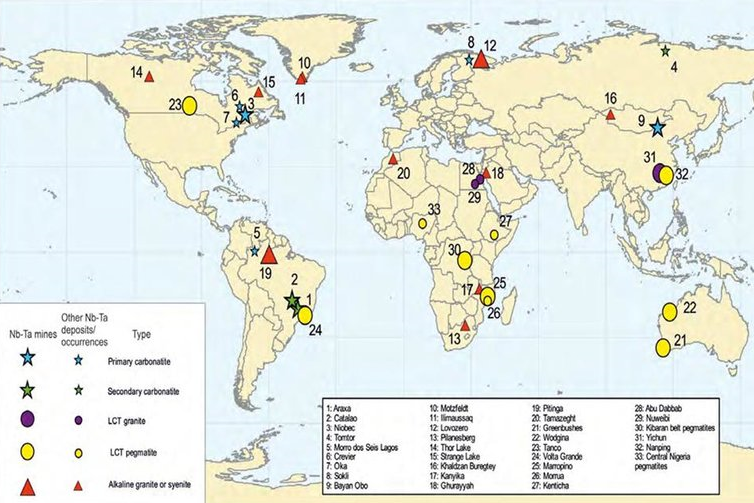

2. Where Is Tantalum Mined?

Tantalum is primarily extracted from coltan—a mineral composed of columbite and tantalite. According to the U.S. Geological Survey (USGS), global tantalum mine production in 2023 was approximately 2,100 metric tons of tantalum content, with several countries contributing significantly:

- Democratic Republic of Congo (DRC): The DRC remains the world’s largest producer, accounting for roughly 38–40% of global tantalum output. However, mining operations here often raise concerns regarding conflict financing and labor conditions.

- Rwanda: Contributing about 22–25% of global production, Rwanda is now the second-largest producer. The country has invested in formalizing its mining sector and increasing traceability in the supply chain.

- Brazil: Brazil ranks third globally, producing around 10–12% of tantalum. Its mines, such as those in the states of Minas Gerais and Amazonas, are important sources of both primary and secondary tantalum.

- Australia: Though it holds some of the largest known tantalum reserves—especially in the Greenbushes and Wodgina mines—Australia’s production has declined in recent years due to market conditions. It accounted for less than 10% of output in 2023 but remains a reliable, ethical source when operational.

- Nigeria and Ethiopia: These countries are emerging players, collectively contributing 5–8% of global production. Nigeria in particular has increased artisanal and small-scale mining (ASM) activity, while Ethiopia has been developing new tantalum resources in Kenticha and elsewhere.

[1]

3. Tantalum Mining Methods

Tantalum is typically extracted through two primary mining approaches. In many African nations, artisanal and small-scale mining (ASM) is the dominant method. This form of mining is highly labor-intensive, relies on minimal mechanization, and provides livelihoods for thousands of individuals. However, it is often informal, loosely regulated, and associated with safety, environmental, and ethical challenges.

In contrast, countries such as Australia and Brazil rely on industrial mining methods. These large-scale operations use advanced machinery and technology to extract tantalum more efficiently and with better environmental controls. Industrial mining also tends to operate under stricter regulatory frameworks, ensuring greater oversight in labor practices and ecological impact.

Once mined, coltan is concentrated and shipped to processing facilities, where it is refined into tantalum oxide or metal powder. Refining involves smelting or chemical processing, often carried out in countries like China, Estonia, or the U.S. The final product is then used in capacitor-grade powder or alloy form.

4. Ethical Concerns of Tantalum Mining

Tantalum sourced from Central Africa—particularly the Democratic Republic of Congo—has long been linked to the financing of armed groups and human rights abuses, earning it the designation of a “conflict mineral.” In regions where artisanal mining is prevalent and regulation is weak, profits from tantalum extraction have at times fueled violence, exploitation, and instability.

To combat these issues, several global initiatives have been implemented to promote ethical sourcing.

- In the United States, Section 1502 of the Dodd-Frank Act mandates that companies publicly disclose whether tantalum in their supply chains originates from conflict-affected areas. The OECD Due Diligence Guidance provides internationally recognized procedures for responsible mineral sourcing.

- Additionally, industry-led programs such as the Responsible Minerals Initiative (RMI) conduct third-party audits to help ensure supply chain transparency and integrity. Together, these measures aim to break the link between tantalum production and conflict, encouraging more responsible mining practices worldwide.

5. Environmental Impact of Tantalum Mining

Tantalum mining can disturb local ecosystems, especially in ASM where regulations are weak. Deforestation, soil erosion, and water pollution are common risks. Industrial mining typically follows stricter environmental protocols, including land rehabilitation and waste management.

Recycling is increasingly promoted as a sustainable alternative. Tantalum recovery from electronics and scrap metal reduces the need for virgin mining and lessens environmental pressure.

Conclusion

Tantalum mining is both an opportunity and a responsibility, requiring attention to ethical sourcing, environmental stewardship, and global cooperation. As industries demand more tantalum, sustainable mining and transparent supply chains will be key to meeting that need without compromising human or environmental health. For more tantalum products, please check Advanced Refractory Metals (ARM).

Reference:

[1] Abo Khashaba, Saif. (2017). Niobium and tantalum deposits.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}