Types and Applications of Biomedical Metal Materials

What Are Biomedical Metal Materials

Biomedical metal materials are specially designed metals and alloys intended for medical applications that require direct interaction with the human body. They are commonly used in devices that temporarily or permanently replace or support biological structures and functions.

To meet the demands of the body’s environment, these materials offer a combination of biocompatibility, mechanical strength, corrosion resistance, and precision manufacturability. Common examples include stainless steel, titanium alloys, cobalt-chromium alloys, magnesium alloys, and tantalum, each chosen based on the specific requirements of the medical application.

This article will introduce common types of biomedical metals, their performance requirements, and specific clinical applications.

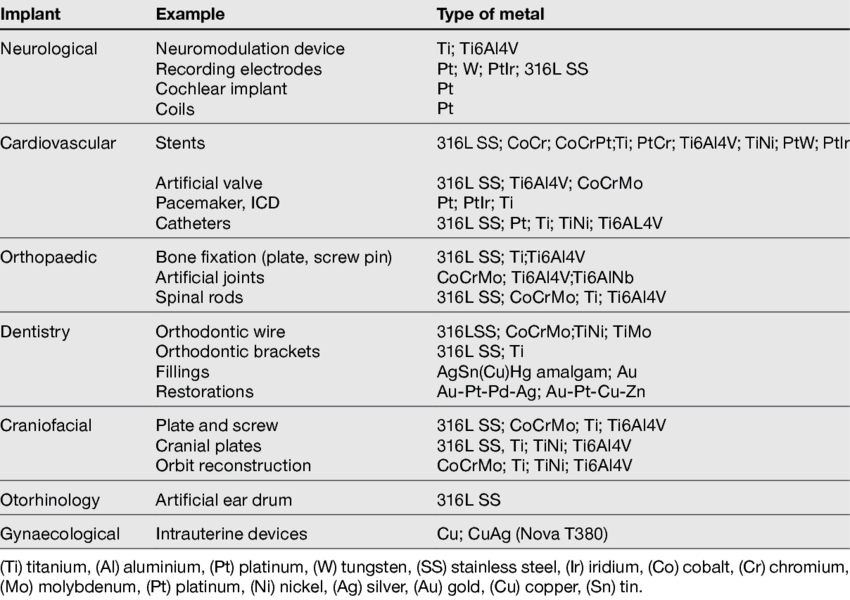

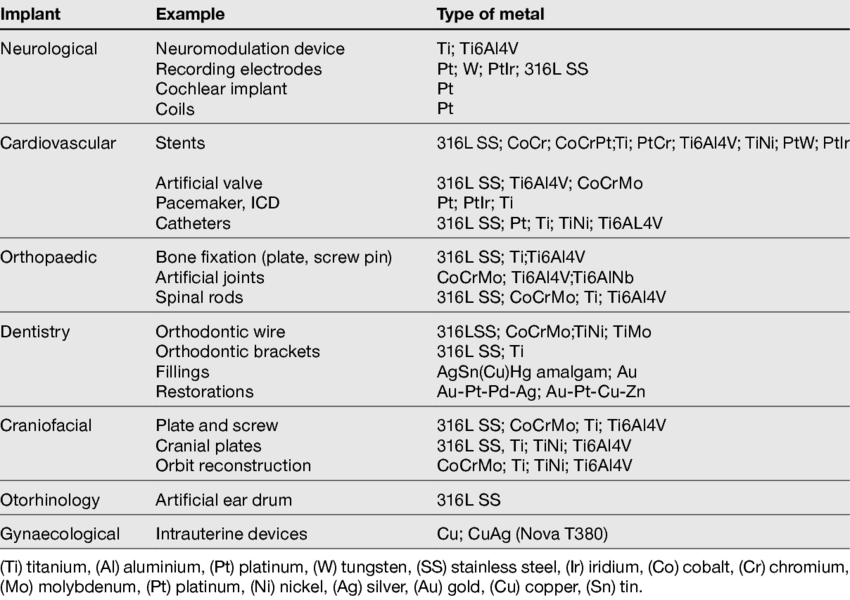

Fig.1 Major Metal Alloys and Their Selected Biomedical Applications [1]

Titanium and Titanium Alloys

Titanium was first isolated in the late 18th century, but its medical use began to flourish in the mid-20th century. In the 1950s and 60s, researchers discovered titanium's remarkable compatibility with human tissue, leading to its adoption in orthopedic and dental implants. Over time, advancements in metallurgy expanded the range of titanium alloys tailored for specific medical applications.

The most widely used grades in medicine are commercially pure (CP) titanium (Grades 1–4) and the titanium alloy Ti-6Al-4V (Grade 5). CP titanium offers excellent corrosion resistance and is typically used in dental implants and surgical instruments. Ti-6Al-4V, known for its superior mechanical strength, is the standard alloy for load-bearing implants such as hip and knee prostheses. There is also growing interest in Ti-6Al-7Nb and other beta alloys for their improved biocompatibility and lower toxicity.

Titanium and its alloys are used across a broad spectrum of medical applications:

- Orthopedic implants such as joint replacements, bone plates, and spinal fixation devices

- Dental implants due to their ability to osseointegrate with bone

- Surgical instruments that require durability and corrosion resistance

- Cardiovascular devices, including pacemaker cases and stents

Stainless Steel

Stainless steel has a long-standing history in medicine, dating back to the early 20th century. Its introduction revolutionized surgical tools and implants due to its corrosion resistance and mechanical strength. By the 1920s, stainless steel became a staple material for reusable medical instruments. The development of specialized medical grades in the latter half of the century further enhanced its role in orthopedic and cardiovascular applications.

Several stainless steel grades are commonly used in the medical field, each selected for specific performance characteristics. AISI 316L, a low-carbon variety, is widely used for implants due to its excellent corrosion resistance, especially in saline environments. AISI 304 is prevalent in non-implantable devices and general surgical tools. For applications requiring high strength and precision, such as cutting instruments, hardenable grades like 17-4 PH and 440C are preferred for their durability and ability to maintain sharp edges.

316L remains the most frequently used implant-grade stainless steel due to its biocompatibility and mechanical stability.

Stainless steel is a workhorse material across many medical applications:

- Surgical instruments such as forceps, scissors, and scalpels

- Orthopedic implants, including temporary bone fixation devices like screws, plates, and pins

- Cardiovascular applications, such as temporary stents and catheter guide wires

- Hospital equipment including trays, tables, and sterilization containers

Precious Metals

Precious metals have been used in medicine for centuries, from gold sutures in ancient civilizations to modern-day implants and diagnostics. Their medical relevance surged in the 20th century with the rise of electronic medical devices and improved understanding of biocompatibility. Due to their resistance to corrosion, electrical conductivity, and inertness in the human body, precious metals remain essential in both therapeutic and diagnostic technologies.

The most commonly used precious metals in the medical field include:

- Platinum and platinum alloys: Valued for stability and conductivity in electrodes and pacemaker components

- Gold: Used in dental restorations, drug delivery, and precision diagnostics

- Silver: Known for its antimicrobial properties, used in wound dressings, catheters, and coatings

- Palladium: Applied in dental alloys and occasionally in implantable electronics

Other Biomedical Metals

In addition to titanium, stainless steel, and precious metals, several other metals and alloys play important roles in biomedical applications due to their unique properties.

Nitinol, a nickel-titanium shape memory alloy, is especially valued for its superelasticity and shape memory effect, making it ideal for flexible stents, guidewires, and orthodontic devices. Cobalt-chromium alloys are widely used in orthopedic implants because of their exceptional strength and wear resistance, particularly in load-bearing joint replacements. Tantalum is prized for its outstanding biocompatibility and corrosion resistance, often employed in porous implants and coatings that encourage bone in-growth and implant fixation. Magnesium alloys have gained attention as biodegradable implant materials that gradually dissolve in the body, eliminating the need for removal surgeries in applications like bone fixation. Zirconium alloys are also utilized in dental and joint implants for their corrosion resistance and excellent compatibility with body tissues.

Further reading: The Versatility of Tantalum Marker Bands: Applications and Benefits

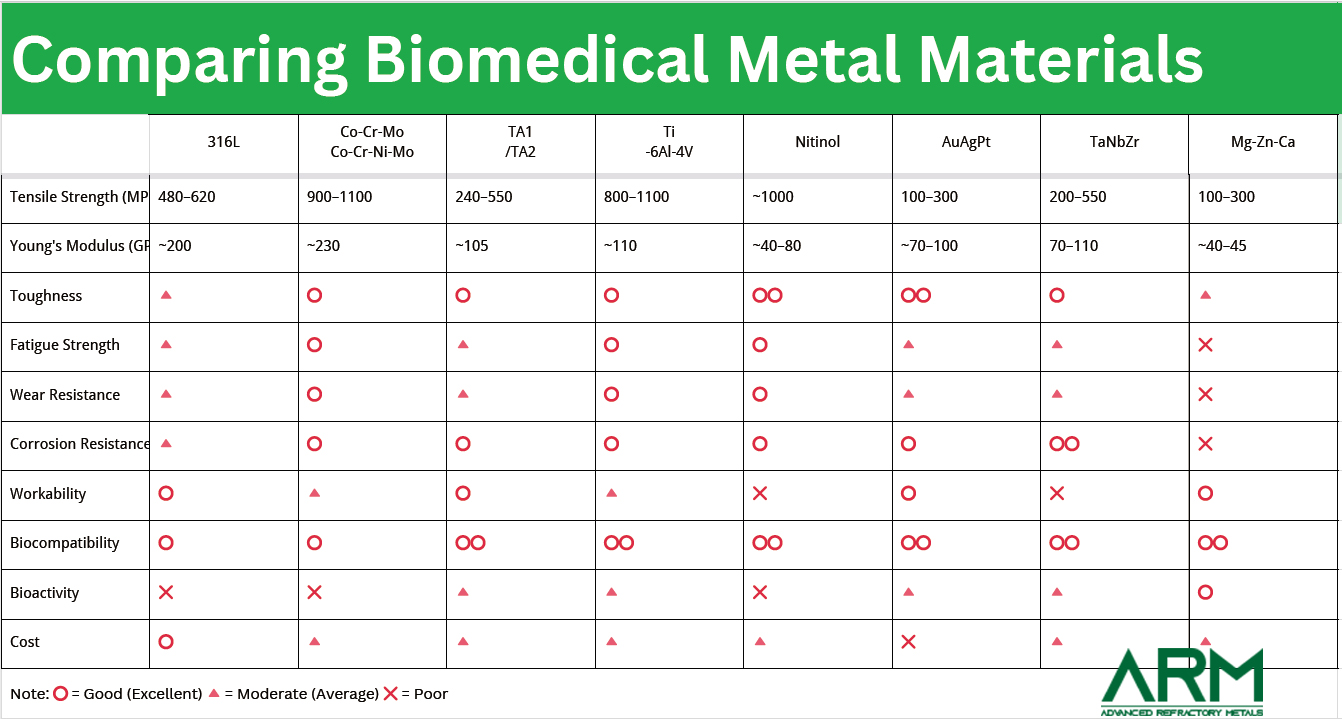

Summary Table: Comparing Properties of Biomedical Metal Materials

Fig.2 Properties of Biomedical Metal Materials

Conclusion

Biomedical metal materials form the backbone of many modern medical devices. Whether it’s the trusted strength of stainless steel, the lasting value of precious metals, the versatility of titanium alloys, or the special abilities of nitinol and cobalt-chromium, each metal has its own important role to play. As materials and technology continue to improve, these metals will keep helping doctors and patients by making medical treatments safer, more effective, and more reliable. For more information, please check Advanced Refractory Metals (ARM).

Reference:

[1] Langley, Adrian. (2015). Modern Metal Implant Toxicity and Anaesthesia.. Australasian Anaesthesia.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}