How to Choose Electrode Wires in EDM Wire Cutting

What Is EDM Wire Cutting?

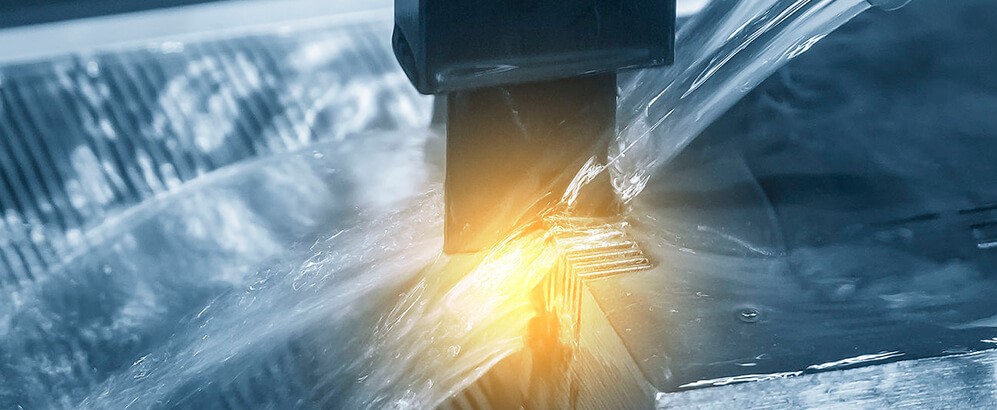

EDM wire cutting is a non-traditional machining process using electrical energy for erosion of electrically conductive workpieces with high precision. The electrode wire, being a thin wire, is used as the cutting tool in the process. A sequence of controlled electric discharges between the wire and workpiece sequentially remove material in a pre-determined path.

EDM wire cutting machines are typically classified into fast wire EDM (high-speed reciprocating wire) and slow wire EDM (low-speed unidirectional wire) systems. Both types are distinct from each other in both their wire feeding system and the nature of their wires.

--Fast Wire EDM

High-speed wire EDM machines typically use molybdenum wire (Mo wire) as the electrode. They are characterized by reciprocating motion of the wire while cutting, where the wire is repeatedly used by the same segment of wire. The dielectric fluid utilized is usually an emulsion (emulsified oil), which is utilized as a coolant and flushing medium.

Fast wire EDM uses reciprocating molybdenum wire and emulsion fluid. It is cost-effective and suited for rough, high-output cutting. It gives less accuracy and finish than slow wire EDM. It also imposes direction marks and requires skilled operation.

--Slow Wire EDM

Slow wire EDM machines utilize a unidirectional wire feed, with the wire being continuously fed and subsequently discarded after use once. Brass wire, coated (zinc-coated) wire, and tungsten wire are common electrode materials, based on the cutting performance intended. The dielectric medium employed is deionized water in most instances, which offers high insulation and flushing capabilities.

Slow wire EDM has high machining accuracy and fine surface finish with minimal striation. It is appropriate for thin features and complex geometries. It, nonetheless, employs increased wire consumption and cost, along with more advanced machines and controls.

Electrode Wire Selection Criteria

The right electrode wire selection is vital in an effort to obtain desired outcomes in EDM cutting. The following parameters should be considered:

In selecting electrode wire for EDM, workpiece thickness and desired cut width should be taken into account. Delicate parts or narrow gaps demand fine wire to achieve greater accuracy and narrower kerf widths. Heavy parts or high-current cutting demand thicker wire, which is more stable and offers better heat dissipation.

Corner detail and geometry also determine wire choice. For a sharp corner or complex shape, finer wire avoids overcutting and preserves dimensional integrity.

Typical wire size ranges differ by material: moly wire usually 0.08 to 0.2 mm, tungsten wire 0.03 to 0.1 mm, brass wire 0.1 to 0.3 mm, and coated or composite wires 0.1 to 0.3 mm.

Further reading: Why Can Molybdenum Wire Cut Metal?

Important Performance Characteristics of Electrode Wires

Electrode wires are tested based on several important performance characteristics. Electrically, their current-carrying capacity governs their potential to sustain stable discharges, while conductivity governs the efficacy of energy transfer during machining. Mechanically, tensile strength, which precludes wire breakage, memory effect, indicating resistance to permanent deformation, and elongation, which balances strength and flexibility, are important.

Geometrically, roundness and diameter accuracy are critical to maintain cutting accuracy and equal spark gaps. Thermally, high melting point and vaporization pressure are required in order to withstand the high temperatures generated while EDMing without degrading excessively.

Comparison Table: Common Types of Electrode Wires

|

Brass Wire |

Molybdenum Wire |

Tungsten Wire |

Coated Wire |

|

|

Content |

Copper-Zinc alloy |

Pure Mo |

Pure W |

Brass core with zinc or multi-layer coating |

|

Diameter (mm) |

0.1 – 0.3 |

0.08 – 0.2 |

0.03 – 0.1 |

0.1 – 0.3 |

|

Uses |

Slow wire EDM |

Fast wire EDM |

Micro-cutting, narrow kerf work |

High-speed, high-precision slow wire EDM |

|

Pros |

Good conductivity, smooth finish, widely available |

High strength, reusable, stable performance |

Very high melting point, excellent wear resistance |

Enhanced flushing, fast cutting, superior surface quality |

|

Cons |

Lower tensile strength, fast consumption |

Expensive, not for slow EDM |

Brittle, expensive, hard to handle |

More expensive than standard brass wire |

For more information, please check Advanced Refractory Metals (ARM).

Conclusion

Selecting the proper electrode wire in EDM wire cutting is fundamental to optimizing performance, reducing costs, and achieving high-quality results. Whether you operate a fast wire EDM system with molybdenum wire or a precision slow wire EDM machine with brass or coated wires, the right choice depends on application demands, material type, cut geometry, and cost constraints.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}