Tungsten in TIG Welding: The Hero in Precise Metal Working

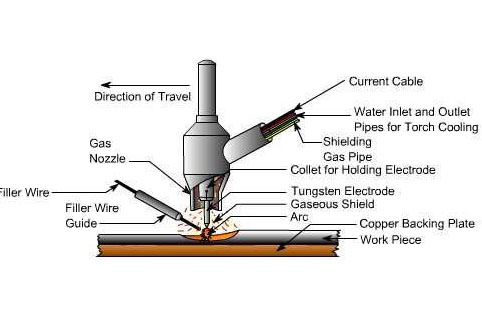

Tungsten is primarily important in TIG Welding, which is also referred to as Gas Tungsten Arc Welding or GTAW. TIG Welding is common in the aircraft industry, the automotive industry, the energy sector, as well as all sectors that require high-precision manufacturing. At the center of TIG Welding is the tungsten electrode, which is an essential, small, and vital tool that provides the precision required to control heat, the arc, as well as the flow of metal.

[1]

Why Tungsten Matters

Tungsten is selected for TIG welding on account of its various unique physical and chemical properties. Tungsten possesses the highest melting point among all metals and stands at 3422°C. This enables it to resist the high temperatures of an arc without melting or deforming. Tungsten's high electrical conductivity translates to a consistent arc to avoid any welding difficulties. Moreover, its low vapor pressure prevents any contamination of the weld by vapors, thus ensuring quality welds are achieved. Tungsten hardness enables it to preserve its pointed or shaped ends. This facilitates precise arc control during welding.

Various Kinds of Tungsten Electrodes

All tungsten electrodes are not the same. Tungsten electrodes are usually doped with trace amounts of thorium, cerium, lanthanum, or zirconium for better performance.

- Pure tungsten electrodes, usually colored green, are generally suited for alternating current (AC) welding of aluminum and, of course, magnesium.

- Thoriated tungsten electrodes, which have a low concentration of thorium, are preferred for their arc stability and are used in direct current (DC) welding of steel and stainless steel primarily due to their ability to produce a strong arc.

- The ceriated and lanthanated electrodes are preferred for their easy starts and greater durability in modern welding processes, while the doped tungsten electrodes are preferred in AC welding processes where sharpening of the electrode tip is important.

The selection of the tungsten electrode is based on the kind of metal being welded, the current being used, as well as the required precision. The selection of the correct tungsten electrode enables the welder to produce high-quality welds with minimal spatters.

[2]

[2]

Preparing the Electrode

The quality of a tungsten electrode largely relies on preparation. When it comes to DC, the electrode needs to be pointed, while for AC, a slightly rounded tip is preferred. When handling the electrode, it is important to do so while clean. Oils from the hands, for instance, may impact the arc. Also, the electrode needs to be sized according to the welding current. Otherwise, it will either burn out or the arc will not be manageable. Preparing the electrode right guarantees it a steady arc, which is responsible for smooth welds.

Cons and Pros of Tungsten in TIG Welding

High melting point, and strong, tungsten electrodes give a TIG welder a lot of flexibility and accuracy. The use of a tungsten electrode and an inert gas shield, most commonly argon, protects the weld from oxidation and contaminants. Thus, a wide variety of metals, ranging from steel and stainless steel, aluminum, magnesium, and titanium, can be welded by a TIG welder. With a higher melting point and greater strength, the tungsten electrodes can stand up to higher temperatures and resist deformation, making them suitable for heavy industrial welding and precision work.

Although it has various advantages, there are also some drawbacks of using the tungsten electrodes. Direct contact of the molten pool can donate impurities to the electrode. Thoriated tungsten can be considered slightly radioactive since it also contains some thorium. However, this problem is eliminated in the case of other alternatives like cerium and lanthanum electrodes. Tungsten electrodes are also considered more expensive than normal rods used in welding.

Data Table: Essential Characteristics of Tungsten Electrodes

|

Property |

Value |

Why It Matters |

|

Melting Point (°C) |

3422 |

Resists deformation under extreme heat |

|

Density (g/cm³) |

19.25 |

Helps maintain tip shape |

|

Electrical Resistivity (Ω·m) |

5.3×10⁻⁸ |

Provides a stable, consistent arc |

|

Thermal Conductivity (W/m·K) |

173 |

Dissipates heat to prevent melting |

|

Thermal Expansion (K⁻¹) |

4.5×10⁻⁶ |

Maintains tip geometry during heating |

|

Common Alloying Elements |

ThO₂, CeO₂, La₂O₃, ZrO₂ |

Improve arc stability and electrode lifespan |

Practical Applications

Tungsten electrodes are essential in sectors requiring accuracy and reliability. In the aviation industry, they are employed in the welding of aluminum, titanium, and stainless steel parts that require resistance to harsh environments. Car manufacturers also use the material in the welding of engine, exhaust, and chassis parts. In the energy industry involving nuclear and thermal power stations, the electrodes are utilized in the welding of corrosion-resistant and high strength steel. Even in aesthetic metalworking, the material enables the creation of flawless designs.

Conclusion

Tungsten is the workhorse of TIG welding. It possesses a distinct set of properties, including a high melting point, electrical conductance, and strength, that enable a welder to make clean, accurate, and strong joints effectively and efficiently for different types of metals. Though tungsten needs to be handled carefully, especially when used as an alloyed electrode, its advantages, including long life, versatility, and accuracy, make tungsten invaluable to the world of welding. Tungsten needs to be used to produce strong, accurate, and sound joints, irrespective of the sector, spanning aerospace, automotive, and power-related industries.

Reference:

[1] Gas tungsten arc welding. (2025, November 30). In Wikipedia.

[2] Ahmed, Javid & Ahmed, Jaleel & Musthak, Md. (2020). Study on behaviour of Process Parameters for TIG Welded Thin plates by Using Taguchi method. 10.6084/m9.figshare.16565001.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}