Titanium Wire Uses & Classification

Titanium Wire Uses & Classification

Pure titanium is a silver-white metal with many excellent properties. In recent years, with the continuous research and development of titanium, more and more titanium products can be found on the market today. And titanium wire is one of the common titanium products in our life. In this article, let's take a look at titanium wire uses and classification.

Titanium Wire Uses & Classification

Titanium Wire Uses

Titanium wire perfectly inherits the advantages of titanium and titanium alloys and has a series of excellent characteristics, such as good corrosion resistance, high specific strength, non-magnetic, high biocompatibility, low impedance to ultrasound, and good shape memory function, and many more. Therefore, titanium and titanium alloy wires are widely used in many fields.

1. At present, more than 80% of titanium and titanium alloy wires are used as welding wires, such as welding various titanium equipment, welding pipes, repair welding of turbine discs and blades of aircraft jet engines, and welding receivers.

2. Due to its excellent corrosion resistance, titanium wire has been widely used in chemical, pharmaceutical, and paper industries. It can be made into a mesh for seawater filters, purified water filters, and chemical drug filters.

3. Titanium and titanium alloy wires are also used to manufacture fasteners, load-bearing members, springs, etc. due to their good overall performance.

4. In the medical and health industry, due to their excellent biocompatibility, titanium and titanium alloy wires are used to manufacture medical devices, such as dental crown fixation and skull fixation implanted in the human body.

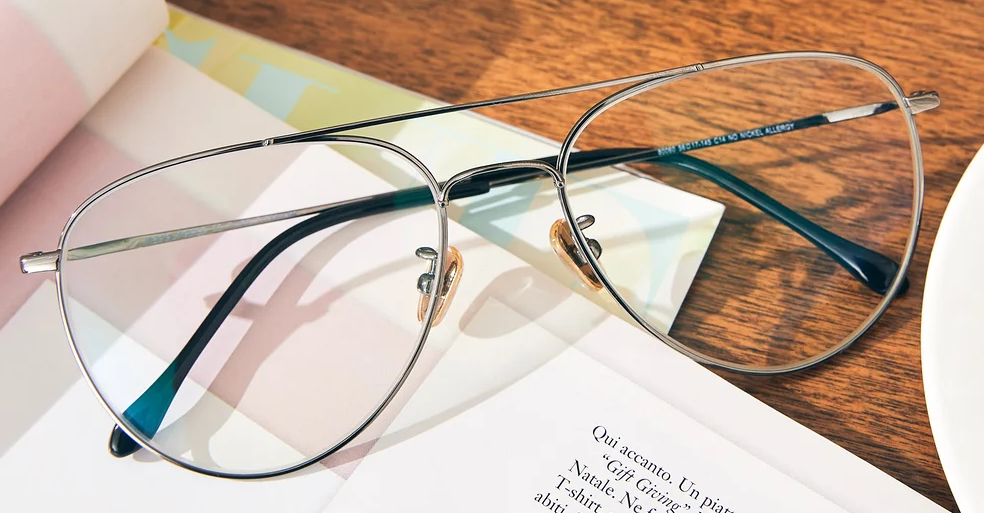

5. Some titanium alloy wires with shape memory function, such as titanium-nickel alloy wires, are used to make satellite antennas, shoulder pads for clothes, women's bras, and eyeglass frames.

6. In the electroplating and water treatment industries, titanium and titanium alloy wires are used to manufacture various electrodes.

Classification of Titanium Wire

According to the different properties of titanium and titanium alloy, different types of titanium wire can be produced. Generally, titanium wire can be divided into the following types: pure titanium wire, titanium alloy wire, pure titanium eyeglass wire, titanium straight wire, titanium welding wire, titanium hanging wire, titanium coil wire, titanium bright wire, medical titanium wire, titanium nickel alloy wire. And different types of titanium wire have different uses.

Titanium Wire Uses & Classification

For example, pure titanium eyeglass wire is mainly used to make eyeglass holders, titanium hanging wire is used to hang weight, and titanium nickel alloy wire is commonly used as a memory alloy material.

Conclusion

With economic development, the demand for titanium and titanium alloy wire is increasing. At present, titanium wire is in short supply and has great development potential.

Thank you for reading our article, hoping it can let you have a better understanding of titanium wire uses & classification. If you want to know more about titanium, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, ARM is a top manufacturer & supplier of refractory metals across the world. We provide our customers with high-quality refractory metals like tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}