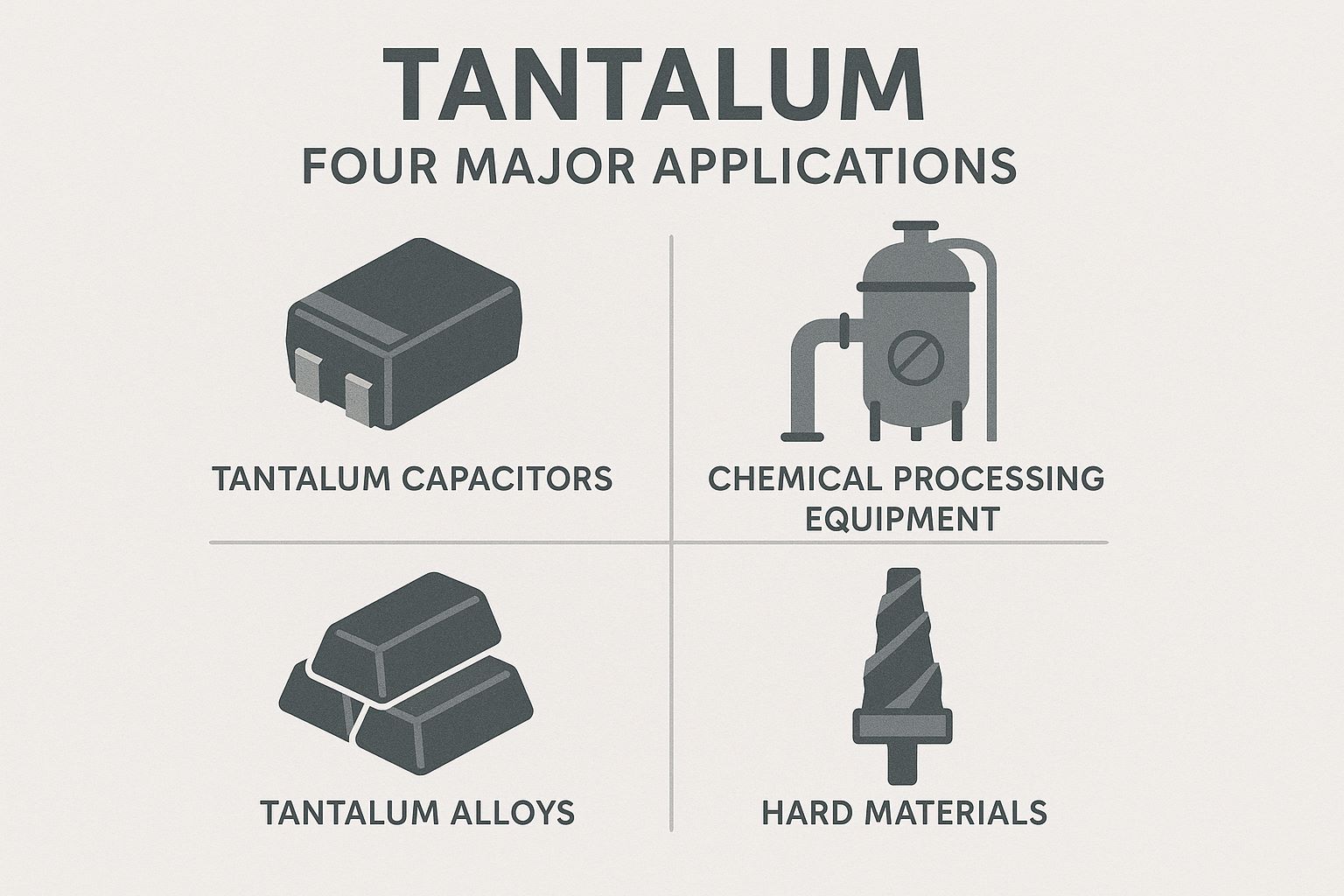

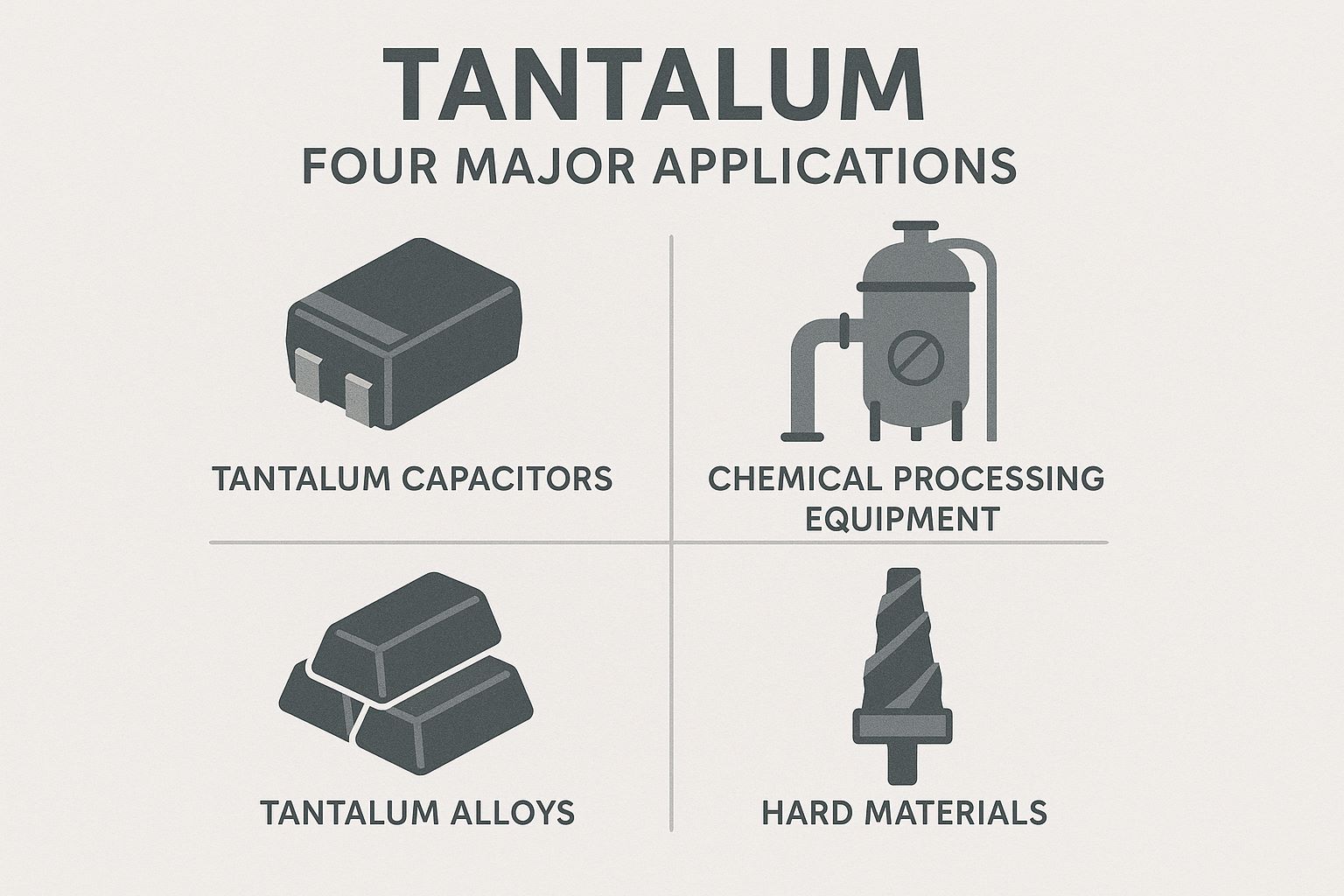

Tantalum: 4 Important Uses and Global Demand

Tantalum (Ta) is a very dense, scarce metal that boasts outstanding corrosion resistance, high melting point, and high strength. All these tantalum properties make it an important element in numerous high-technology uses. According to latest market analysis, the overall market value of tantalum was close to $387.3 million in 2024 and is expected to grow up to a maximum of $550.4 million by 2030 with a 5.1% CAGR (Next MSC, 2024). All due to four pillar applications: chemical processing plant equipment, tantalum capacitors, hard materials such as tantalum carbide, and tantalum alloys.

1. Tantalum Capacitors: The Backbone of Modern Electronics

Tantalum capacitors are an indispensable component of the enormous array of electronic products ranging from smartphones, notebooks, and automotive applications to renewable energy products. Their small volume per capacitance, thermal shock resistance, and low leakage current render them extremely ideal for high-performance small devices.

The world market value for tantalum capacitors in 2024 was $2.22 billion and is projected to grow to $4.25 billion in 2034 with 6.7% growth (FactMR, 2024). Growth drivers are primarily increased demand for miniature electronics and new solid polymer electrolytes with greater performance and safety than the traditional manganese dioxide-based tantalum capacitors (Mordor Intelligence, 2024). In spite of the danger of competition from the multi-layer ceramic capacitors and the aluminum electrolytic, the latter are nonetheless selected in high-reliability applications because of their efficiency and durability.

2. Chemical Processing Equipment: Corrosion Resistance in Harsh Environments

The corrosion resistance of tantalum is a favorite among chemical processing, pharmacy, and specialty chemical production companies. Tantalum components such as heat exchangers, reactors, piping, and lining containers are applied for dealing with aggressive chemicals such as concentrated sulfuric acid and hydrochloric acid.

Although tantalum is extremely costly to buy in the first place, its performance over a very long period of time and very little maintenance to do have made it an extremely high return on investment. The toughness of the metal in very corrosive atmospheres has served to make it always utilized instead of such commodities as specialty steels, glass, and plastics. Tantalum finds application in gas purifying appliances, electron emitting devices, and vacuum equipment at high temperatures, which depicts the adaptive nature of the metal towards chemical and advanced applications.

3. Tantalum Alloys: High-Temperature Performance Improvement

Alloys of tantalum are also strategically useful in aerospace due to their ability to have high thermal stability, high melting point, and oxidation resistance. Tantalum alloys find applications in building structures like turbine blades, rocket nozzles and building frames to impart stability in harsh environments.

Alloys are typically filled with tungsten or metallic elements to provide mechanical strength in addition to resistance against corrosion. The global market for tantalum alloys expands with advances in new aerospace technology and material requirements featuring high-stress, high-temperature applications (24 Chemical Research, 2024). Specifically, nickel-based superalloys with the inclusion of tantalum have improved grain structure, hardness, and tensile strength to offer improved service life and performance compared to unalloyed metals.

4. Hard Materials: Hardening Cutting Tools and Wear Parts

Tantalum carbide (TaC) is one of the hardest ceramic materials widely used to improve the quality of cutting tools and wear parts. Its corrosion resistance, heat stability, and hardness are very valuable in drilling, mining, and precision machining.

The global market for tantalum carbide totaled $190.8 million in 2024 and is anticipated to grow to $341 million by 2034 at a CAGR of 6% (GMI Insights, 2024). Tantalum carbide is mostly mixed with other carbides such as niobium carbide (NbC) and titanium carbide (TiC) in order to improve hardness, toughness, and thermal shock resistance. Though other materials such as TiC-based carbides are in higher demand, tantalum carbide continues to be crucial in very wear-resistant and high-performance cutting tools.

Conclusion

The combination of corrosion resistance, high melting point, and mechanical strength in tantalum ensures its application in all high-technology industries. Major applications include miniaturized electronic devices, resistant chemical process equipment, aerospace materials, and hard materials. Due to increasing technology demands and aerospace, chemical, and electronics industries expansion, global demand for tantalum will increase consistently. For more tantalum products, please check Advanced Refractory Metals (ARM).

References

1. Next MSC, 2024. Tantalum Market Report 2024-2030.

2. FactMR, 2024. Tantalum Capacitor Market Analysis 2024-2034.

3. Mordor Intelligence, 2024. Tantalum Capacitors Market Overview.

4. 24 Chemical Research, 2024. Tantalum Alloy Strip Market Trends.

5. GMI Insights, 2024. Tantalum Carbide Market Report.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}