Rhenium Foil: Properties, Applications, and Comparison

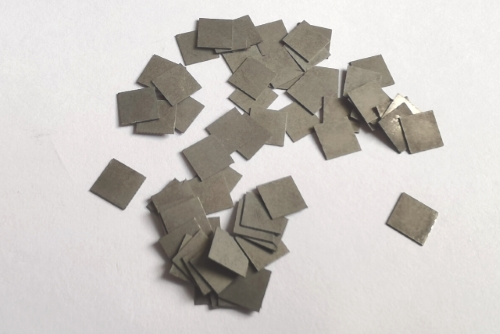

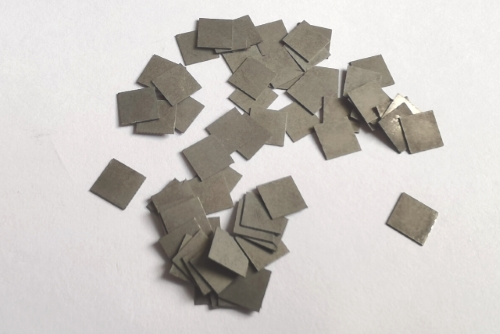

Rhenium is one of the rarest and most valuable refractory metals. It is prized for its high melting point, strength retention at extreme temperatures, and chemical stability. In foil form, rhenium’s unique traits make it indispensable in aerospace, electronics, and chemical industries where few other materials can survive.

We are going to have a comprehensive overview of rhenium foil—its properties, applications, and how it compares with other refractory metal foils. Hope that you can have better understanding of rhenium foil with these cases and data.

1. Physical and Mechanical Properties of Re Foil

Rhenium (atomic number 75) sits in Group 7 of the periodic table, neighboring tungsten and molybdenum. It is silvery-white, dense, and remarkably stable at high temperatures.

Below lists the key properties of rhenium foil:

|

Property |

Value |

Notes |

|

Melting point |

3,180 °C |

Third highest after tungsten and carbon |

|

Density |

21.02 g/cm³ |

Higher than tungsten (19.25 g/cm³) and tantalum (16.65 g/cm³) |

|

Tensile strength (RT) |

~900 MPa |

Retains >500 MPa at 2,000 °C |

|

Ductility (elongation at RT) |

>30% |

Allows deep forming without cracks |

|

Thermal conductivity |

~48 W/m·K |

Moderate, useful for thermal management |

|

Oxidation limit in air |

500–600 °C |

Requires vacuum or inert atmosphere for higher temps |

|

Acid resistance |

Stable in HCl, H₂SO₄, HNO₃ at RT |

Minimal degradation over extended exposure |

For example, NASA’s J-2X rocket engine program used rhenium-lined combustion chambers that maintained structural integrity after repeated firings at >2,400 °C, where nickel-based superalloys failed due to creep and oxidation.

2. Manufacturing Rhenium Foil

Producing rhenium foil is a precision-intensive process:

- Powder preparation – Rhenium is recovered as a by-product of molybdenum or copper refining, often as ammonium perrhenate (NH₄ReO₄).

- Reduction – Hydrogen furnaces reduce the oxide to metallic powder.

- Pressing and sintering – Powder is pressed into billets and sintered at 1,800–2,200 °C in a high-vacuum or hydrogen atmosphere.

- Rolling – Multiple rolling passes reduce thickness to as little as 0.025 mm; intermediate annealing restores ductility.

- Final surface finish – Foils are polished or chemically cleaned to meet aerospace-grade surface roughness (Ra < 0.4 μm).

3. Applications of Rhenium Foil

3.1 Aerospace and Space Propulsion

- Rocket thruster liners: Rhenium foil is often diffusion-bonded to graphite substrates, then overlaid with iridium for oxidation resistance. NASA’s NSTAR ion engine used this configuration to survive 30,000+ hours of operation in space.

- Heat shields: In satellite re-entry modules, thin rhenium layers act as erosion-resistant barriers at peak heating phases (>1,800 °C).

3.2 Electronics and Electrical Components

- X-ray tube targets: Rhenium–tungsten composite targets use a rhenium layer to reduce surface evaporation, improving lifespan by up to 50% in continuous medical imaging systems.

- Electrical contacts: In aerospace switching devices, rhenium’s resistance to arc erosion reduces contact pitting, extending maintenance cycles.

- Vacuum electronics: Rhenium foil grids in traveling-wave tubes remain dimensionally stable above 1,500 °C for prolonged operation.

3.3 Chemical Processing

- Catalyst substrates: In reforming units, rhenium foil-coated supports enhance platinum catalyst life by resisting sintering.

- Acidic environment liners: Rhenium foil has been used in small-scale high-purity acid production where tantalum was cost-prohibitive or mechanically insufficient.

3.4 Scientific Research

- High-temperature crucible liners: In thermogravimetric analysis above 2,200 °C, rhenium foil prevents sample contamination from ceramic crucibles.

- Thin-film deposition: Foil serves as both a base layer and an evaporation source in molecular beam epitaxy setups.

4. Comparison with Other Refractory Metal Foils

|

Property / Metal |

Rhenium (Re) |

Tungsten (W) |

Molybdenum (Mo) |

Tantalum (Ta) |

|

Melting Point (°C) |

3,180 |

3,422 |

2,623 |

3,017 |

|

Density (g/cm³) |

21.02 |

19.25 |

10.22 |

16.65 |

|

Tensile Strength (RT) |

~900 MPa |

~750 MPa |

~550 MPa |

~200 MPa |

|

Ductility (RT) |

Excellent (>30%) |

Poor–Moderate |

Good |

Good |

|

Strength @ 2,000 °C |

>500 MPa |

~450 MPa |

<300 MPa |

~100 MPa |

|

Corrosion Resistance |

Excellent |

Good |

Good |

Outstanding |

|

Typical Service Life in Rocket Liner Tests |

2–3× tungsten |

Baseline |

Not suitable |

Not suitable |

In sum:

- Rhenium outperforms tungsten in ductility and creep resistance, despite tungsten’s slightly higher melting point.

- Molybdenum and tantalum have their niches, but neither can match rhenium in prolonged ultra-high-temperature vacuum service.

- In aerospace trials, rhenium foil liners have been shown to double engine service life compared to tungsten, justifying the higher material cost in critical missions.

5. Conclusion

From deep-space ion thrusters to long-life X-ray targets, rhenium foil’s rare combination of high-temperature strength, ductility, and chemical resistance has proven itself in field trials and laboratory tests alike.

For engineers designing components where failure is not an option, rhenium foil remains the material benchmark among refractory metals. For more information, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}