How Are Special Refractories Used in Steel Making?

Steel doesn’t come easy. Between raw materials, heat, and heavy machinery, you need materials that can take the punishment and keep working. That’s where special refractories come in. They’re the quiet workhorses of the steel industry—tough, heat-resistant, and absolutely essential. Let’s go over what they are, where they’re used, and how they help in steel production.

What Are Special Refractories?

Special refractories are a group of heat-resistant materials built to handle extreme conditions—high temperatures, sudden temperature changes, corrosion, and mechanical wear. These aren’t your average bricks. They’re engineered to hold up in the harshest parts of a steel plant. You’ll find them made from materials like alumina, zirconia, magnesia, silicon carbide, and even some rare earth compounds.

Think of them as the armor that protects the equipment that gets steel from raw ore to finished product. Without them, the furnaces and vessels would fall apart in no time.

Table 1 Common Types of Special Refractories

|

Types |

Key Properties |

Typical Applications |

|

Magnesia-Carbon (MgO-C) |

High thermal resistance, slag resistance |

Electric arc furnaces, ladles, converters |

|

Alumina-Carbon (Al₂O₃-C) |

Good corrosion resistance, high strength |

Slide gates, nozzles, ladle linings |

|

Zirconia (ZrO₂) |

Extreme thermal shock resistance, purity |

Nozzles, tundishes, continuous casting zones |

|

Silicon Carbide (SiC) |

High thermal conductivity, erosion resistance |

Furnace linings, taphole blocks |

|

Alumina-Magnesia |

Good spalling resistance, wear resistance |

Steel ladles, impact zones |

|

Spinel (MgAl₂O₄) |

Stability under load, corrosion resistance |

Slag lines, intermediate zones in ladles |

|

High Alumina (>90%) |

High melting point, good volume stability |

Induction furnaces, castable linings |

|

Chromite-Based |

Good slag resistance, basic environment stable |

Vessels with aggressive slags |

|

Castables and Ramming Mixes |

Easy to shape or patch, good bonding |

Repairs, complex shapes, backup linings |

For more information, please check Advanced Refractory Metals (ARM).

What Are the Applications of Special Refractories?

Special refractories show up anywhere there’s high heat and heavy wear. Some of their common applications include:

- Ladles and tundishes: These hold and transfer molten steel. Refractories keep the steel hot and the container safe.

- Electric arc furnaces (EAFs): Lining the inside to handle direct exposure to molten metal, electric arcs, and slag.

- Slide gates and nozzles: Precision areas that control the steel flow need highly durable refractories.

- Continuous casting equipment: Refractories here help guide and control the molten steel into its final shape.

- Induction furnaces: Used in smaller operations or for special alloys, they still need reliable refractory linings.

Each of these areas faces a combination of thermal shock, abrasion, and chemical attack. Special refractories are selected based on which problem is most pressing.

Further reading: What Are the Special Refractories Widely Used in Modern Industry?

[1]

[1]

How Are Special Refractories Used in Steel Making?

Steelmaking is a hot, rough business. From melting scrap and ore to shaping liquid steel into solid slabs or billets, it’s nonstop exposure to heat and slag. Here’s how special refractories help at each key step:

- Melting Stage

In electric arc furnaces, you get temperatures above 1,600°C. The inner walls are lined with magnesia-carbon bricks or alumina bricks. These refractories resist both heat and slag corrosion. Without them, the furnace shell would fail fast. - Refining and Holding

Once melted, the steel is moved to ladles or refining vessels. Special refractories keep the steel clean—resisting chemical attack and preventing contamination. They also hold heat, so the steel doesn’t cool too quickly. - Casting Stage

Molten steel flows from ladle to tundish to mold. Slide gates and nozzles control this flow. Zirconia-based refractories are often used here—they hold up under high pressure and rapid temperature swings. - Repair and Maintenance

In high-wear zones, refractories can be injected or gunned into place between heats. These aren’t just bricks—they come in castables, ramming masses, or pre-formed shapes, depending on the job.

It’s not a one-size-fits-all situation. Engineers and metallurgists pick specific refractories based on the steel grade, furnace type, and even the type of slag used. It’s all about balance—thermal resistance, chemical durability, mechanical strength, and cost.

Summary

Special refractories might not get the spotlight, but without them, steelmaking would grind to a halt. They’re the unsung heroes behind the scenes—taking the heat, handling the pressure, and letting the process run smoothly. Like any good set of tools, the right refractory in the right spot can save time, cut costs, and keep things safer.

Reference:

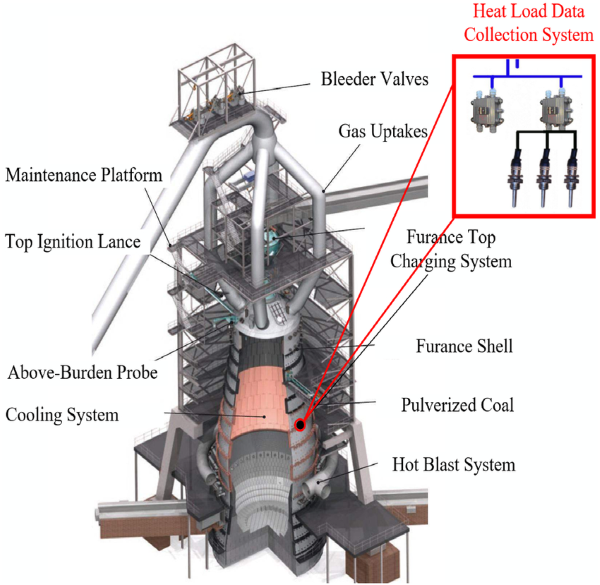

[1] Xu, Hong-Wei & Qin, Wei & Sun, Yan-Ning & Lv, Youlong & Zhang, Jie. (2023). Attention Mechanism-Based Deep Learning for Heat Load Prediction in Blast Furnace Ironmaking Process. Journal of Intelligent Manufacturing. 35. 10.1007/s10845-023-02106-3.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}