5 Interesting Facts about Tantalum

5 Interesting Facts about Tantalum

Tantalum is a metallic element with a bluish tint and excellent ductility. Tantalum is the third most refractory metal, only after tungsten and rhenium, with a melting point of 2980 ℃, element symbol Ta, atomic number 73, and a density of 16.68g / cm³. Except for the basics above, what else should we know about tantalum? Here are 5 interesting facts about tantalum you may want to know.

Interesting Facts about Tantalum

Interesting Facts about Tantalum - 1. How Tantalum Gets Its Name

In 1802, the Swedish chemist A.G. Ekaberg (1767-1813) discovered new elements while analyzing niobium-tantalite ore from Scandinavia. He named the element Tantalum after Tantalus, the son of Zeus in Greek mythology.

Interesting Facts about Tantalum - 2. The Distribution of Tantalum Resources in the World

Tantalum, as a rare metal, has a relatively small amount of resources on the earth compared with other metals. Globally proven tantalum resources are mainly distributed in Australia and Brazil. Australia alone accounts for nearly 62% of global tantalum reserves, followed by Brazil, which accounts for 36% of the total.

According to data released by the US Geological Survey (USGS) in 2015, the global reserves of tantalum resources exceeded 100,000 tons, including 67,000 tons in Australia and 36,000 tons in Brazil. The United States, Burundi, Canada, Congo (DRC), Ethiopia, Mozambique, Nigeria, and Rwanda all have tantalum resources, but the exact amount is uncertain.

Interesting Facts about Tantalum - 3. Global Tantalum Production

According to data released by the US Geological Survey (USGS) in 2015, global tantalum mine production totaled 1,200 tons in 2014, an increase of 30 tons over 2013. The main producing countries are Rwanda, Brazil, Congo (DRC), and Mozambique. Among them, Rwanda's production accounts for half of the global production.

Interesting Facts about Tantalum - 4. The Applications of Tantalum

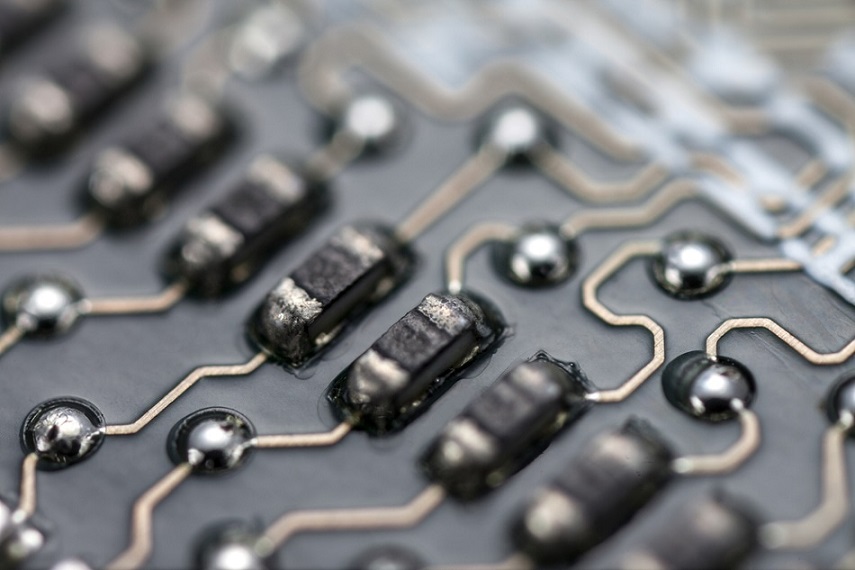

Tantalum has a series of excellent properties such as high melting point, low vapor pressure, good cold workability, high chemical stability, strong resistance to liquid metal corrosion, and a large dielectric constant of the oxide film on the surface.

Therefore, tantalum has important applications in high-tech fields such as electronics, metallurgy, steel, chemicals, cemented carbide, atomic energy, superconducting technology, automotive electronics, aerospace, medical and health, and scientific research.

Interesting Facts about Tantalum - 5. The Recycling of Waste Tantalum

Tantalum resources are few and expensive, and the use of secondary resources is of special significance. The secondary resources of niobium tantalum include two parts: one part is the waste generated during the smelting and processing of niobium-tantalum, and the other part is the components and parts scrapped during the use of niobium-tantalum products. Tantalum currently recovered from secondary resources accounts for about 15% to 20% of the amount of tantalum raw materials.

The Recycling of Waste Tantalum

According to the type of waste materials, tantalum niobium waste materials mainly include pure metals, compounds, and alloys. Pure metal waste is generally recovered by vacuum smelting, electron beam smelting, and hydrogenation powder smelting after chemical cleaning. Tantalum and niobium wastes, such as compounds and alloys, have many types and complex compositions, so various recycling processes have been developed.

Conclusion

Thank you for reading our article, and we hope it can help you have a better understanding of tantalum. If you want to know more about the interesting facts about tantalum, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, ARM is one of the leading manufacturers & suppliers of refractory metals across the world. We provide our customers with high-quality refractory metal products such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very affordable price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}