Everything about TZM Alloys

TZM alloys occupy a unique position in the world of high-performance metals. Understanding TZM alloys—what they are, what differentiates them from other refractory metals, and where they are utilized—means taking a closer examination of their composition, properties, and applications.

TZM Alloys: Basics & Properties

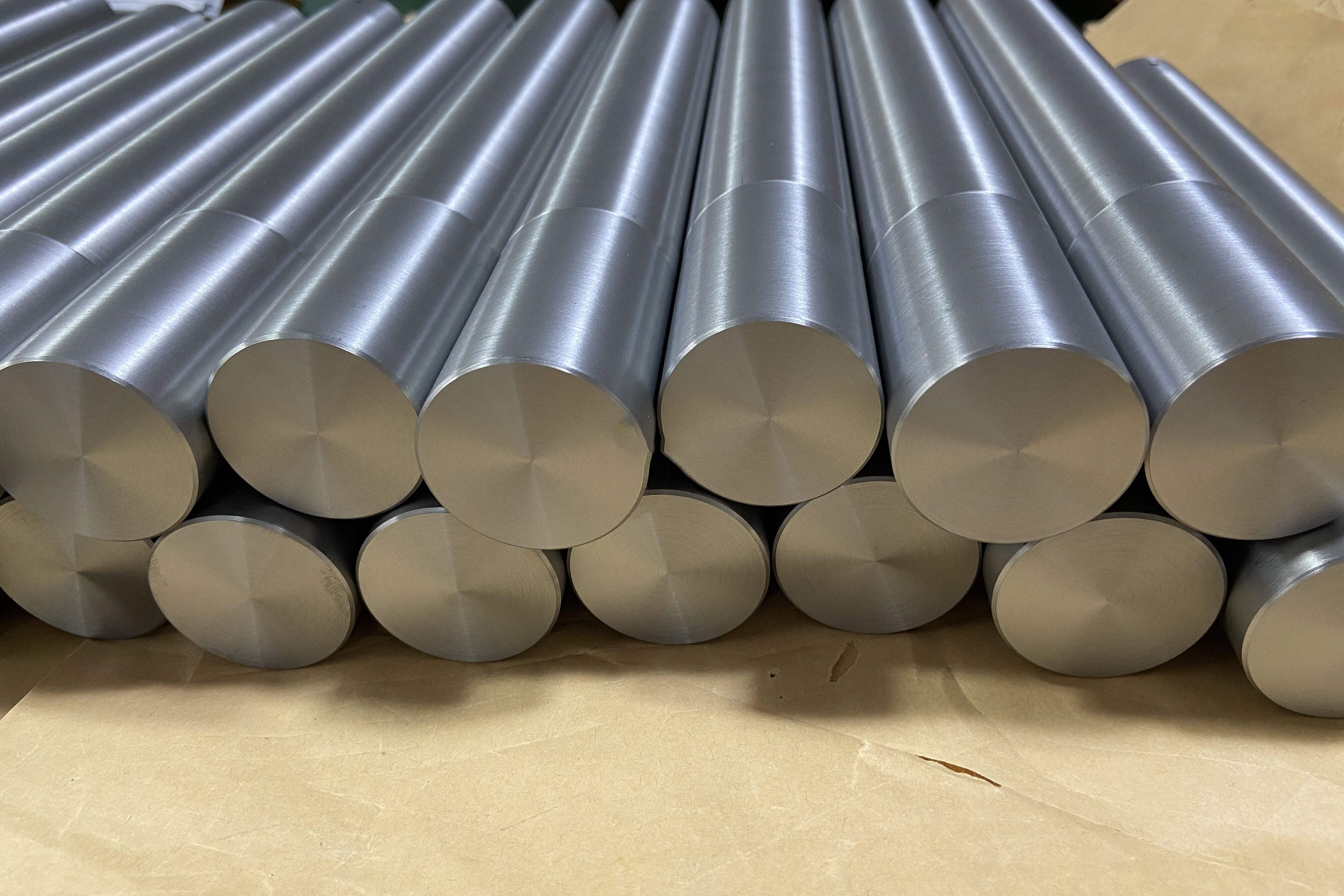

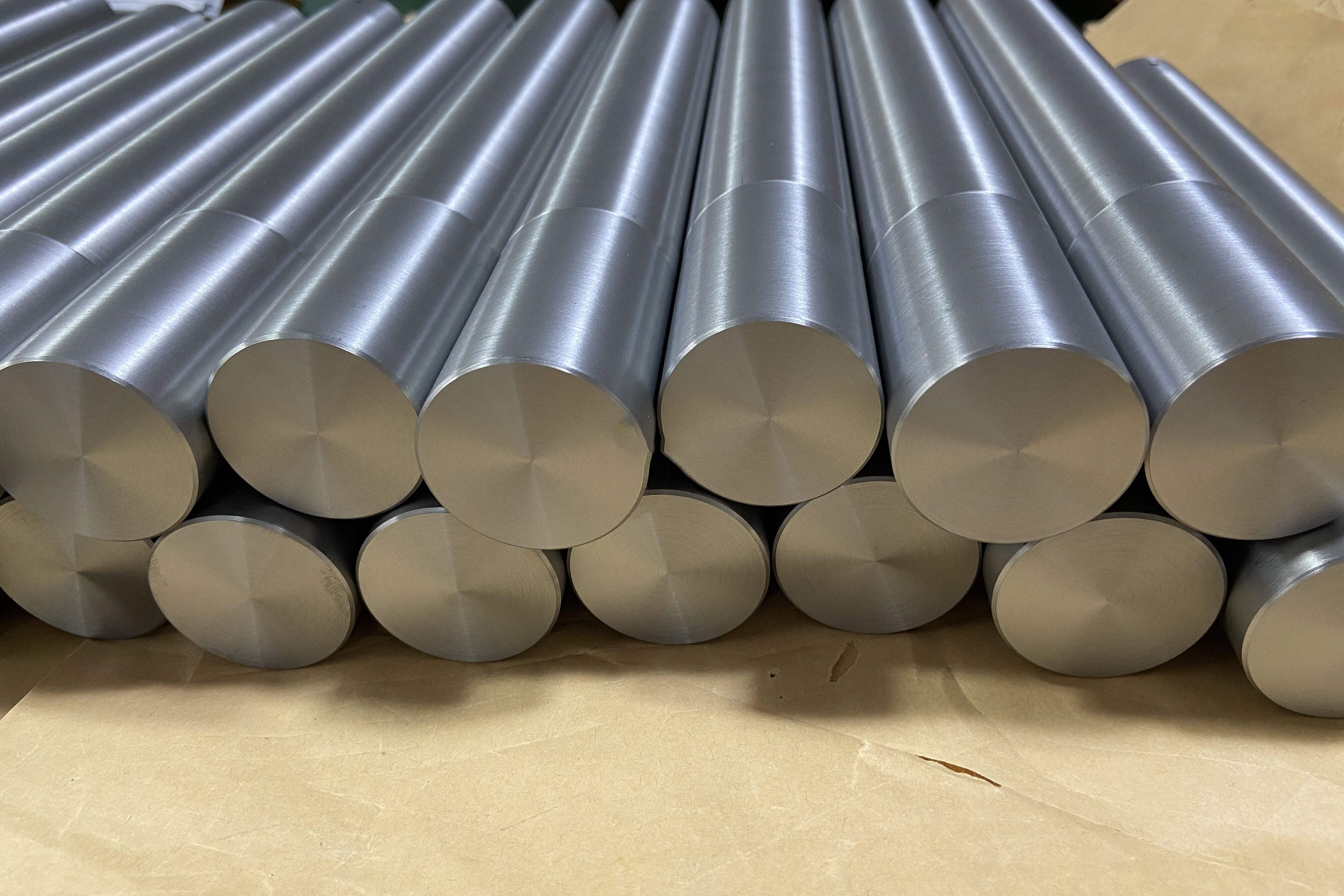

1. What Is TZM Alloy? Composition, Structure, and Primary. Properties

TZM alloy is a molybdenum-based refractory metal alloy primarily composed of molybdenum (Mo) with small amounts of titanium (Ti), zirconium (Zr), and sometimes carbon (C). Though these trace additions, not exceeding 0.5% Ti, 0.08% Zr, and 0.01% C, are of immense significance in enhancing the performance of the alloy.

TZM possesses a body-centered cubic (BCC) crystal structure, inherited from molybdenum. The BCC structure provides natural high-temperature stability, the low titanium and zirconium levels acting as fine carbides that retard grain growth and improve creep resistance. The combination makes TZM far stronger than molybdenum at high temperatures, preserving good ductility at room temperatures.

The following are the significant properties of TZM:

• First-rate strength at high temperatures (up to 1,200°C in air and higher in vacuum or inert atmosphere).

• Low thermal expansion, which ensures minimal dimensional shift in precision applications.

• GUI (heat conductivity), which allows for rapid dissipation of heat in hot environments.

• Dual-the-strength machinability against other refractory metals, thanks to controlled grain structure and alloying.

2. How Titanium, Zirconium, and Molybdenum Interact in TZM Alloy

The alloying of titanium, zirconium, and molybdenum defines TZM's high performance. Titanium and zirconium are carbide formers. When alloyed with carbon, they create extremely fine carbides distributed in the matrix of molybdenum. These carbides pin the grain boundaries, thereby preventing uncontrolled grain growth at higher temperatures—a process that would otherwise decrease pure molybdenum.

Molybdenum adds the base of the alloy, which provides it with a high melting point (2,623°C) and better creep resistance. Without the trace amounts of the minor alloying elements, molybdenum would develop fast grain growth when heated for an extended period, leading to structure failure. However, TZM maintains its mechanical properties even under severe thermal stress and is therefore ideal for aggressive industrial use.

3. The Science behind TZM Alloy's High-Temperature Strength

At higher temperatures, metals creep in time—creep. TZM has high-temperature strength because of the interaction between its BCC molybdenum matrix and the submicron carbides of titanium and zirconium. The carbides act as dislocation barriers to dislocation movement, the atomic structure's microscopic deformations in the metal that lead to creep.

In addition, TZM is very resistant to thermal fatigue, a condition that arises when metals keep on expanding and contracting due to continuous exposure to fluctuating temperatures. Its low coefficient of thermal expansion reduces internal stress buildup, preventing cracking or warping of precision parts. Combined, these features make TZM a good material for use in cases where strength and dimensional stability are critical.

TZM Alloys: Comparisons & Alternatives

1. TZM Alloy vs Tungsten: Which Material Conducts Heat Better?

Tungsten has an extremely high melting point (~3,422°C) compared to TZM's (~2,623°C), a desirable trait in which absolute resistance to temperature is paramount. Tungsten is also a disadvantage in being heavier (~19.3 g/cm³ versus TZM's ~10.2 g/cm³), leading to heavier parts—a serious drawback in aerospace. Tungsten is also brittle at room temperature, more difficult to machine, and prone to cracking by impact or thermal cycling.

On the other hand, TZM has combined high-temperature strength coupled with lower density and better workability. Examples:

• TZM retains ~400 MPa at 1,200°C but with pure tungsten, ductility falls rapidly with increasing temperature.

• TZM thermal expansion is ~5.5 × 10^-6 /K but tungsten is higher (~4.5 × 10^-6 /K) but with lower practical thermal stability in actual parts because of its brittleness.

In practice, TZM is more desirable for high-precision furnace parts, rocket nozzles, and aeronautical components where weight, strength, and machinability are a trade-off. Severe heat applications such as high-intensity arc electrodes or plasma-facing components are left for tungsten.

2. TZM Alloy vs Molybdenum: What's the Real Difference?

Pure molybdenum has excellent high-temperature properties but can creep at temperatures above 1,100°C. By adding titanium and zirconium to create TZM, creep resistance is greatly improved:

•Creep rate at 1,200°C: Pure Mo ~1.2 × 10^-3 %/h; TZM ~0.2 × 10^-3 %/h

•Yield strength at 1,200°C: Pure Mo ~150 MPa; TZM ~400 MPa

This improvement allows TZM to undergo dimensional stability under long-term high-temperature stress, which is beneficial for dies, furnace fixtures, and aerospace.

Related reading: TZM Alloy vs Pure Molybdenum

3. TZM Alloy vs Mo-La (Lanthanum Oxide Doped Molybdenum) Alloys

Mo-La alloys enhance oxidation resistance by adding lanthanum oxide but are weaker in high-temperature creep strength than TZM. For example:

•1,200°C, TZM has 400 MPa yield strength; Mo-La ~250 MPa

•Thermal conductivity of TZM (~135 W/m·K) is higher than Mo-La (~120 W/m·K), allowing better heat dissipation in die-casting dies.

While Mo-La is used in oxidizing environments, TZM benefits in situations where mechanical strength and precision are required under adverse heat.

Related reading: TZM vs. Mo-La: Which Molybdenum Alloy Is Better?

4. Alternatives to TZM Alloy in Modern Aerospace and Furnace Applications

Certain other high-temperature substances include:

•Tungsten and tungsten alloys: Excellent temperature resistance but dense and brittle

•Rhenium-based alloys: Extremely good high-temperature strength but expensive

•Ceramics (SiC, graphite composites): Excellent oxidation resistance and wear resistance but dense and difficult to machine

TZM remains the material of choice for use in applications that require a combination of dimensional stability, high-temperature strength, and machinability.

TZM Alloys: Applications

1. Why TZM Alloy Is the Go-To Material for Extreme Heat Applications

Those industries that operate continuously at temperatures higher than 1,000°C rely on TZM due to its exceptional strength and stability. Electrode supports for high-temperature furnace parts and tooling are a few of the common uses. Low thermal expansion and high thermal conductivity of TZM ensure stable performance and reduce thermal deformation or localized overheating.

2. TZM Alloy in Aerospace: From Rocket Nozzles to Jet Engines

Aerospace applications place very strict demands on materials. Rocket thrust chambers and nozzles, jet engine components, are exposed to severe thermal gradients and mechanical stresses. Low density, high temperature strength, and dimensional stability of TZM render it a first choice for such applications in order to meet safety and performance at extreme conditions.

3. Applications of TZM Alloy in Metal Forming and Die Casting Industry

In die casting and metal forming, dies, punches, and molds experience regular thermal cycling as well as severe stress. TZM alloys are better to work in these conditions since they are resistant to creep, possess low thermal expansion, and have sufficient thermal conductivity. Through maintaining the precise dimensions and structure, TZM enhances the quality of the product and tooling life.

Conclusion

In summary, TZM alloys are the perfect blend of engineering and chemistry. Of all the refractory metals, TZM walks the line between high-temperature strength, machinability, and dimensional stability better than anyone else. Its versatility is the reason it is used universally in aerospace, furnace systems, and metalworking industries, cementing TZM's status as the go-to alloy for extreme use.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}